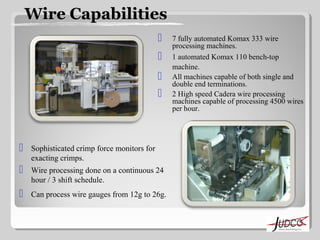

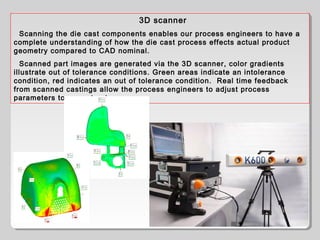

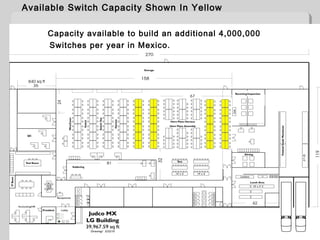

This document provides information about Judco Manufacturing's facilities and capabilities for producing automotive switches and components. It describes their manufacturing facilities in Harbor City, CA and Mexicali, Mexico, which include injection molding machines, wire processing equipment, and assembly lines operating 24/7. Engineering capabilities including CAD software, rapid prototyping, and testing equipment are also summarized. Judco has extensive experience in designing and manufacturing switches and electrical components for automotive OEMs.