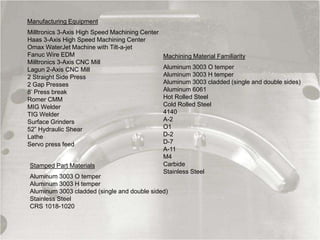

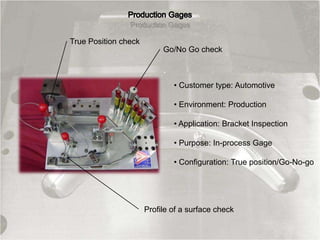

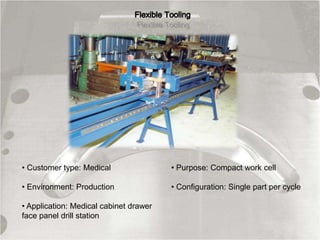

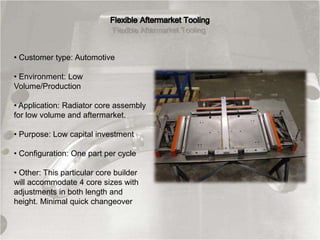

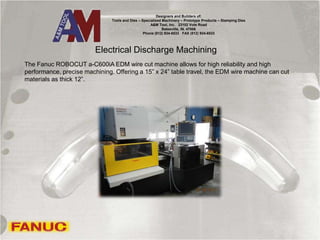

A&M Tool, Inc. is a tool, die, and machinery design and manufacturing company located in Batesville, Indiana. They have over 100 years of combined experience in tooling and manufacturing. Their services include tool design, manufacturing engineering, and contract manufacturing. They have various CNC machining centers, stamping presses, a waterjet cutting machine, and an EDM machine. Their customers come from industries like automotive, medical, and consumer products.