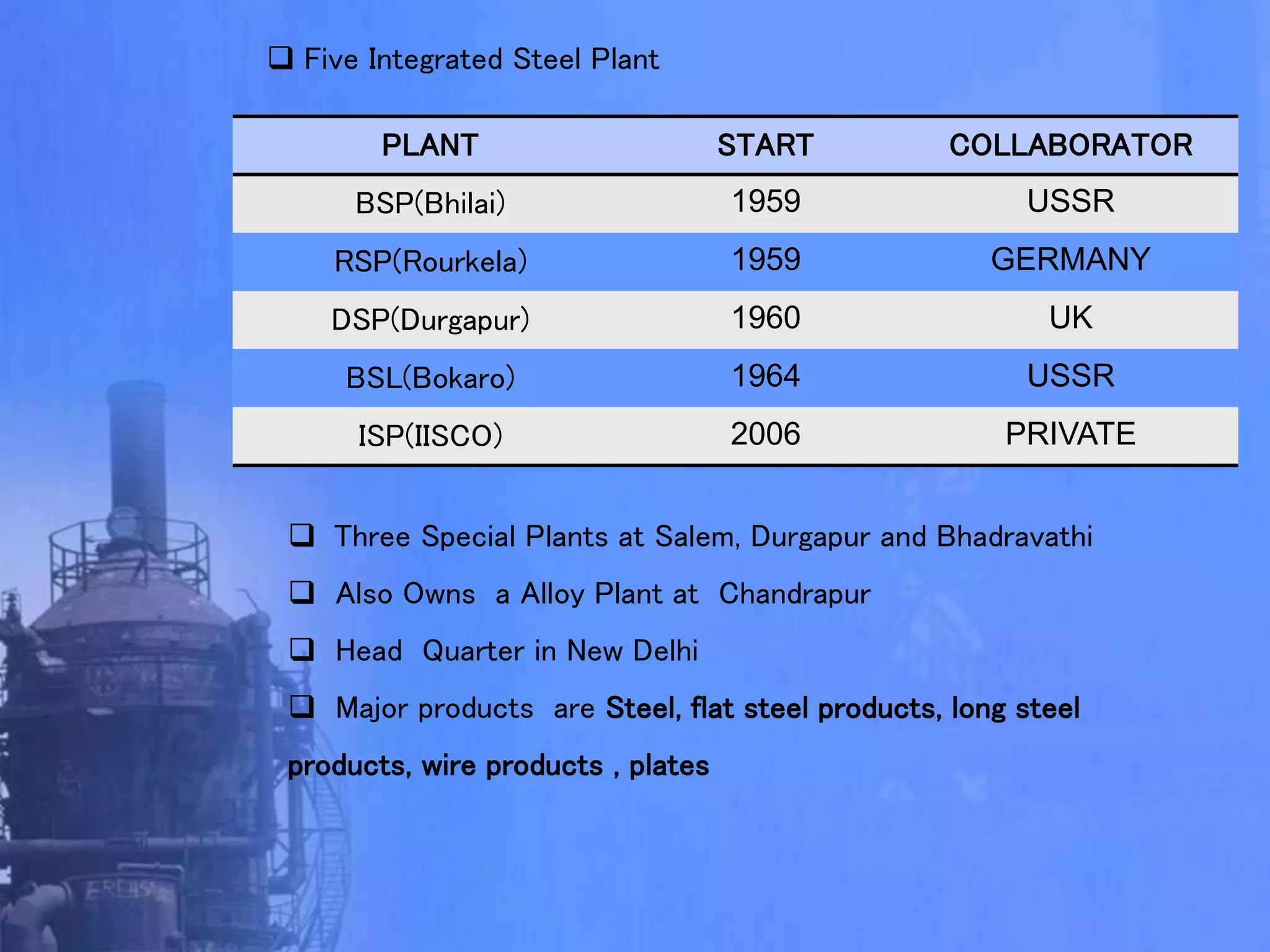

The document outlines a seminar presentation on the Bhilai Steel Plant, a key facility of the Steel Authority of India Limited (SAIL), highlighting the plant's production capabilities and achievements. It provides an overview of SAIL, the plant's history, major products, and operational details, including its electrical repair shop and power systems. Notably, Bhilai Steel Plant is recognized as India's primary producer of steel rails and has received multiple awards for excellence in safety and quality management.