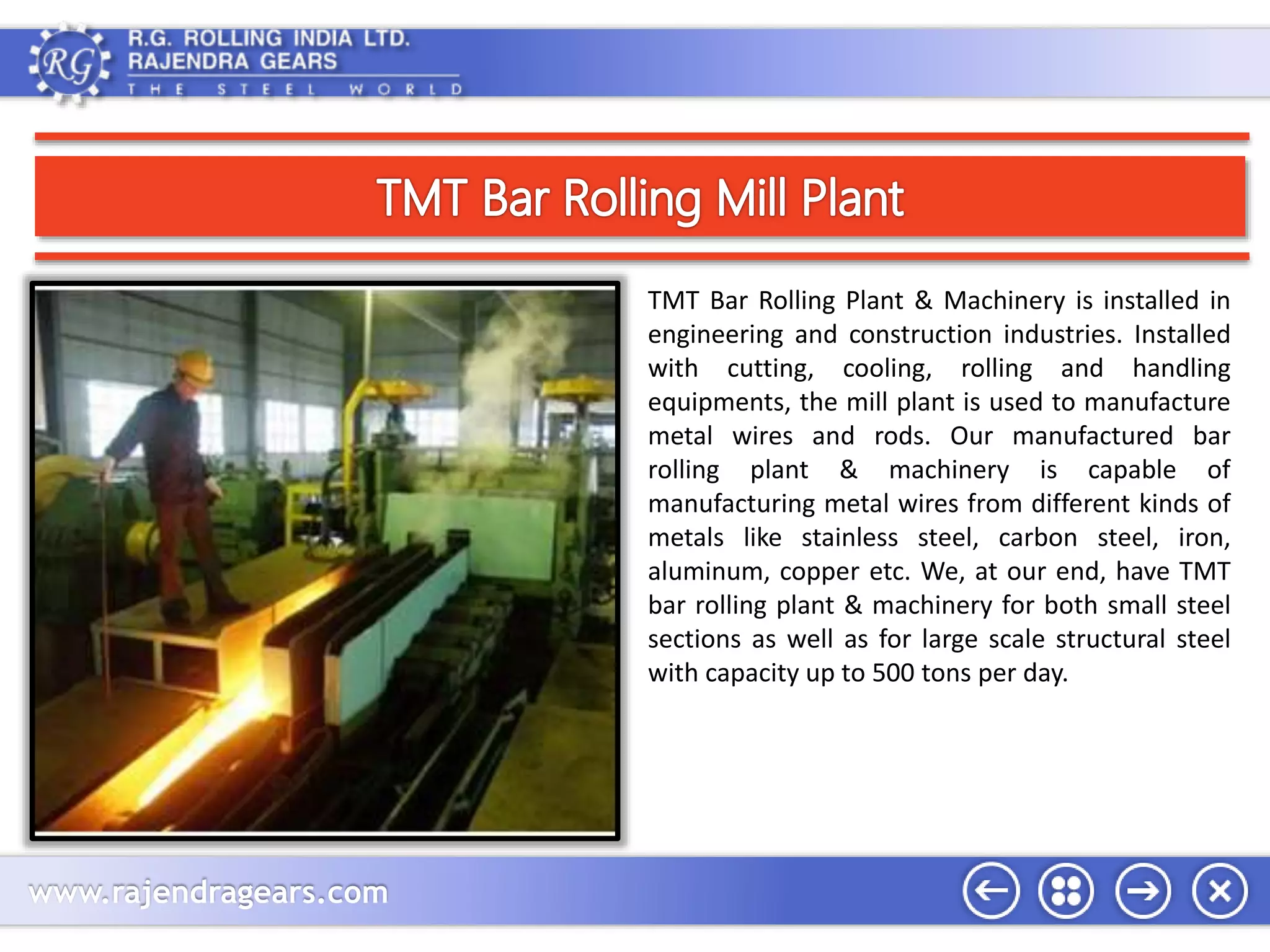

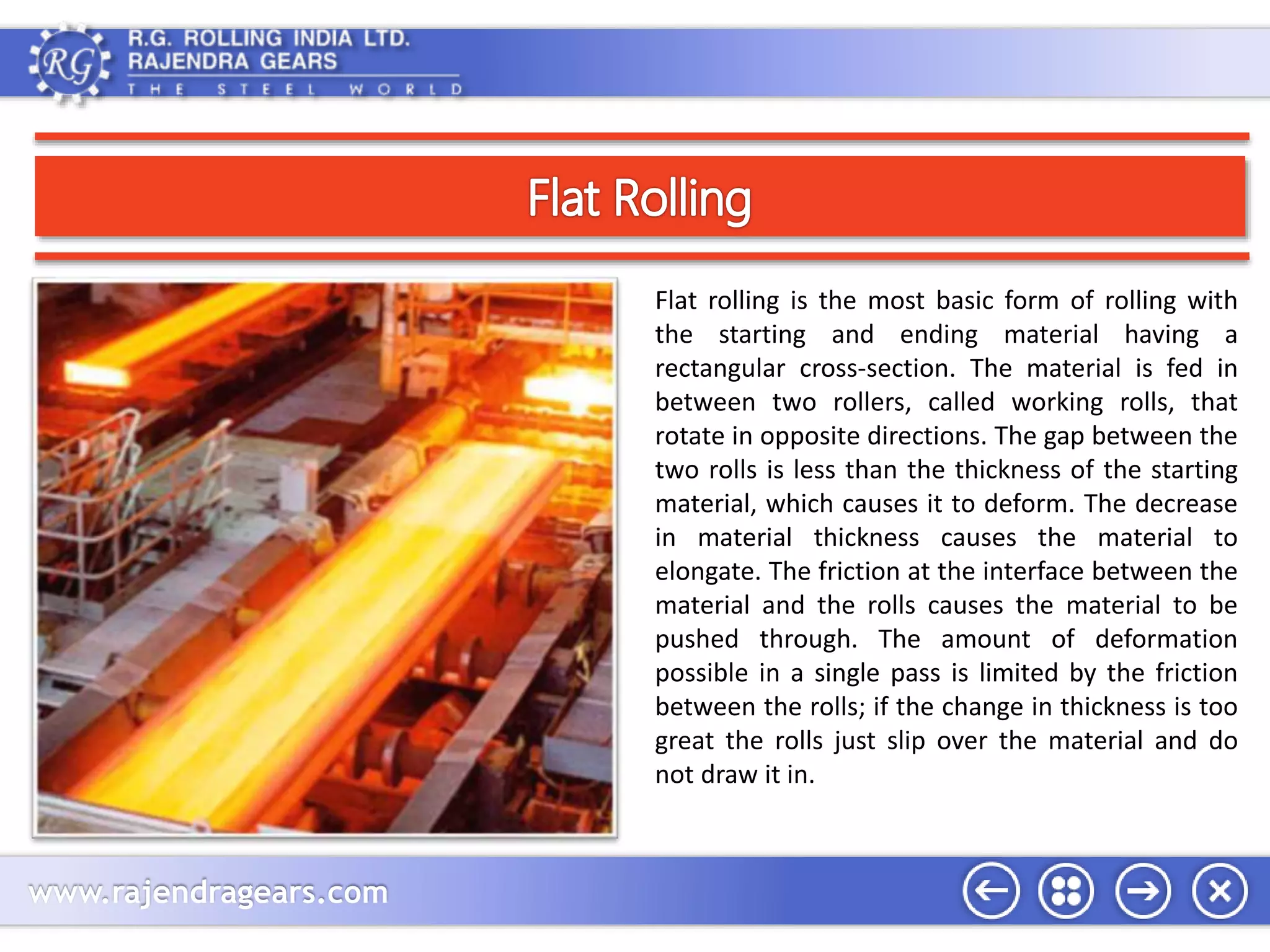

Rajendra Gears Co. & R.G. Rolling India Ltd. is a leading manufacturer and exporter of rolling mill plants and machinery based in Ghaziabad, India, specializing in high-quality equipment and consultancy services for the rolling mill industry since 1980. The company prides itself on utilizing advanced technology, quality control measures, and a customer-centric approach to deliver tailored solutions, ensuring reliability and performance in manufacturing various steel products. With over 30 years of experience, Rajendra Gears has built a solid reputation in the industry, supported by ISO certifications and a commitment to quality and timely delivery.