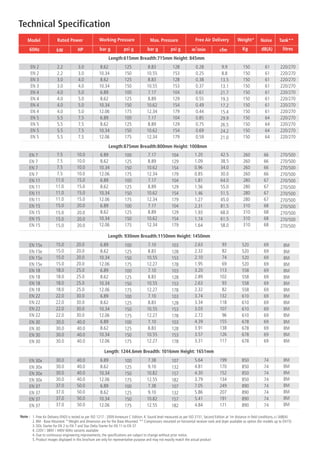

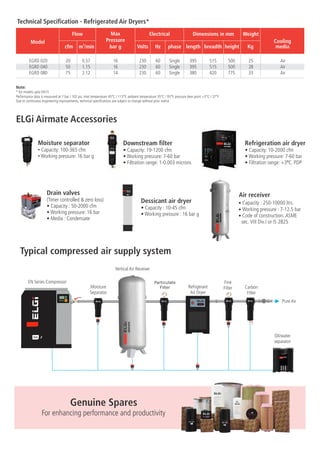

Elgi, established in 1960, designs and manufactures diverse air compressors, emphasizing reliability, innovative technology, and energy efficiency through continuous R&D and strategic partnerships. The company produces a range of products including oil-lubricated and oil-free rotary screw compressors, with modern manufacturing operations across multiple countries, ensuring high quality and advanced technology. Their EN series screw compressors feature a compact design, low maintenance requirements, and are ideal for various industrial applications, backed by industry-leading warranties and support.