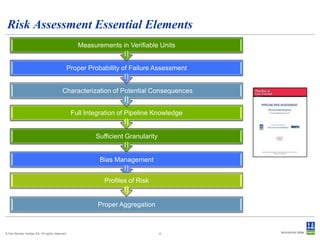

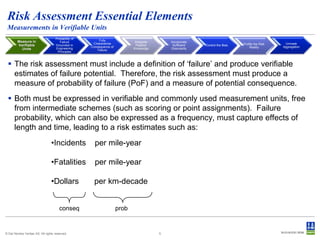

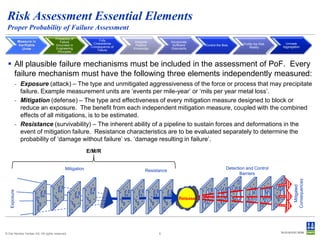

This document outlines essential elements for effective risk assessment of pipelines and pipeline segments. It discusses elements in three main categories: (1) proper probability of failure assessment grounded in engineering principles, including estimating exposure, mitigation, and resistance; (2) fully characterizing potential consequences; and (3) fully integrating available pipeline knowledge. The goal is for risk assessments to produce profiles of changing risk along pipelines using unbiased, granular methods and proper aggregation, leading to optimized safety and integrity decision-making.

![Risk Assessment Essential Elements

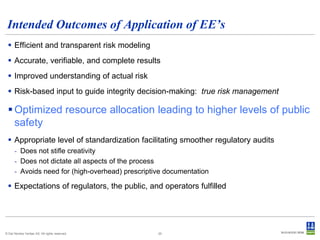

Proper Probability of Failure Assessment (continued)

Measure in

Verifiable

Units

Probability of

Failure

Grounded in

Engineering

Principles

Fully

Characterize

Consequence of

Failure

Integrate

Pipeline

Knowledge

Incorporate

Sufficient

Granularity

Unmask

Aggregation

Profile the Risk

Reality

Control the Bias

Measuring Mitigation

Strong, single measure

Or

Accumulation of lesser measures

1 - (remaining threat)

Remaining threat = (remnant from mit1) AND (remnant from mit2)

(remnant from mit3) …

AND

Mitigation

Mitigation % = 1-[(1-mit1) x (1-mit2) x (1-mit3)…]

Exposure

Coating

© Det Norske Veritas AS. All rights reserved.

8

CP

Mitigated

Exposure

Mitigation % =](https://image.slidesharecdn.com/mangoldessentialelementsofriskassessment-wkm-131129123240-phpapp02/85/Mangold-essential-elements-of-risk-assessment-8-320.jpg)

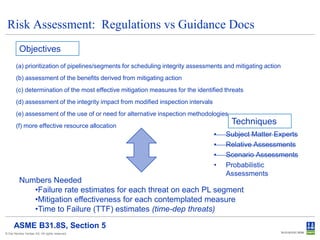

![Risk Assessment Essential Elements

Proper Aggregation

Measure in

Verifiable

Units

Probability of

Failure

Grounded in

Engineering

Principles

Fully

Characterize

Consequence of

Failure

Integrate

Pipeline

Knowledge

Incorporate

Sufficient

Granularity

Control the Bias

Profile the Risk

Reality

Unmask

Aggregation

A proper process for aggregation of the risks from multiple pipeline segments must

be included.

Summarization of the risks from multiple segments must avoid simple statistics or

weighted statistics that mask the actual risks

PoF total = PoF1 + PoF2 + PoF3 + PoF4 + … PoFn

PoF total = Avg(PoF1, PoF2, … PoFn)

Overall PoF is probability of failure by [(thd pty) OR (corr) OR (geohaz)…]

Ps = 1 - PoF

Overall Ps is probability of surviving [(thd pty) AND (corr) AND (geohaz)….]

So…

PoFoverall = 1-[(1-PoFthdpty) x (1-PoFcorr) x (1-PoFgeohaz) x (1-PoFincops)]

© Det Norske Veritas AS. All rights reserved.

19](https://image.slidesharecdn.com/mangoldessentialelementsofriskassessment-wkm-131129123240-phpapp02/85/Mangold-essential-elements-of-risk-assessment-19-320.jpg)