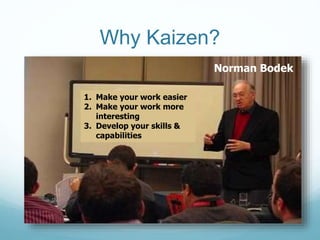

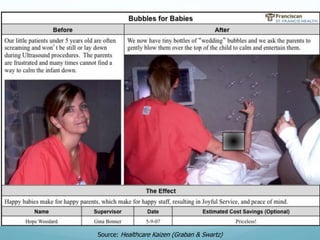

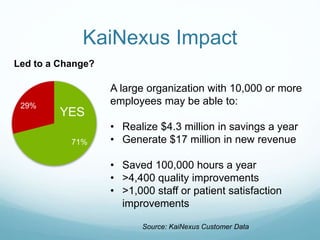

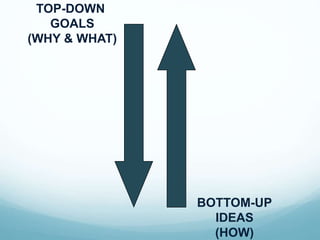

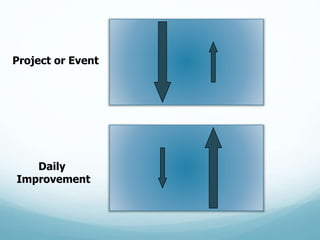

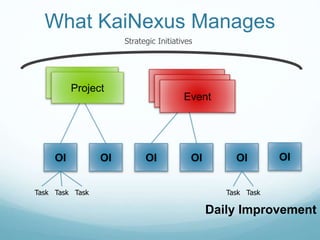

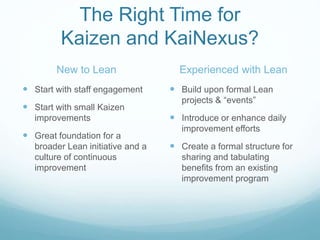

Kaizen and KaiNexus are presented as tools for continuous process improvement. Kaizen emphasizes small, incremental changes and empowering workers. KaiNexus is a web-based platform that manages the lifecycle of improvement opportunities from submission to resolution. It allows tracking outcomes across projects, events, and daily improvements. Leaders are encouraged to coach teams and participate in improvements to set an example. The presentation argues that starting improvement efforts helps create a culture of continuous learning and that organizations should not wait for a perfect culture before beginning.