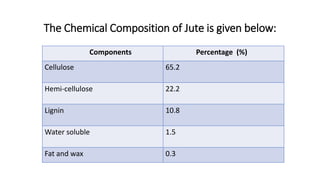

Jute is a natural fiber known as the "Golden Fiber" that comes from the stem of the jute plant. It is the second most produced textile fiber in the world after cotton. Bangladesh is the largest cultivator and producer of raw jute. Jute requires a warm, humid climate and is harvested between 120-150 days after planting. It is composed mainly of cellulose and lignin. Jute is used to make sacks, packaging cloth, carpets, and mixed with wool for clothing due to its strength and low cost. While jute processing can cause pollution, the fiber is biodegradable and adds nutrients to soil. Its global harvest and sale amounts to over 3 million tons annually worth