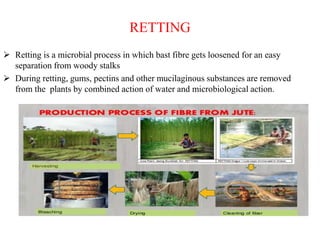

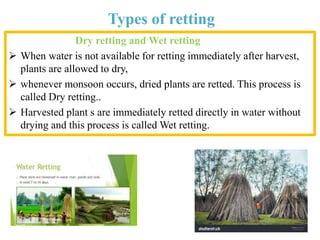

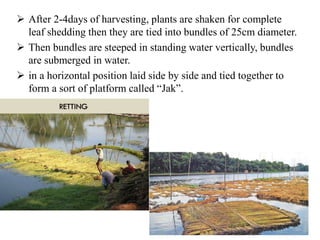

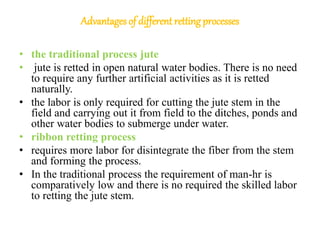

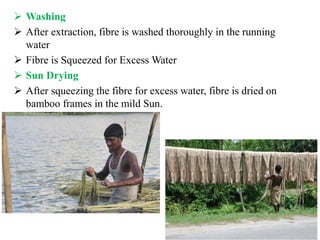

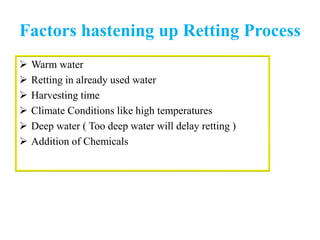

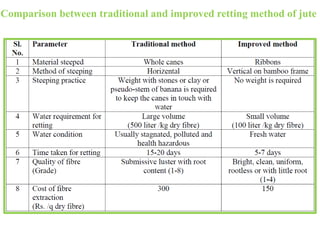

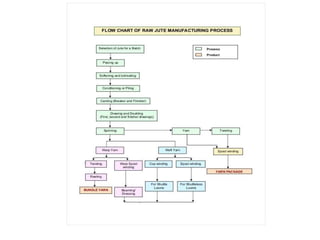

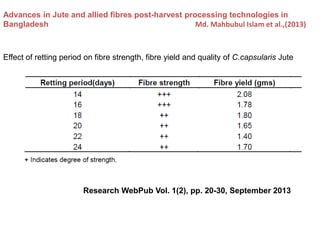

This document discusses the process of retting jute plants to extract the fibers. It begins with an introduction to jute as an important natural fiber crop and raw material. There are then sections that describe the different types of retting processes, including dry and wet retting. Wet retting involves submerging bundled jute plants in water for 8-30 days to allow microbes to loosen the fibers from the stalk. The document provides details on best practices for wet retting, such as water temperature and depth of submergence. It also notes potential issues like under-retting or over-retting fibers. Finally, it compares traditional and improved retting methods and discusses factors that influence fiber quality.