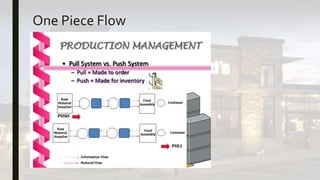

McDonald's is the world's leading fast food organization, founded in 1955. It has maintained its position through adopting lean practices like poka-yoke, one-piece flow, and kanban to reduce waste. McDonald's new "Made for You" kitchen system and mobile ordering experience the future concept improve process time and customer service. Constant innovation in its layout plans, from indoor seating to self-service kiosks, helps McDonald's adapt to changing customer demands.