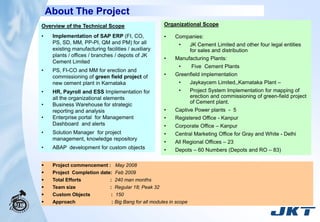

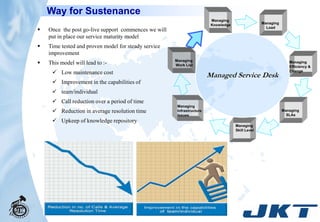

JK Cement Ltd is a large cement producer in India seeking to implement SAP ERP to integrate its various legacy systems and manual processes. It has five cement plants, five captive power plants, and sells cement and derivatives across India through 23 offices and 60 warehouses. The SAP implementation will cover key modules to integrate finance, supply chain, production, sales, and human resources. The goals are to improve financial management, reduce costs through optimized procurement and distribution, and increase revenue growth through better customer insights. The project will follow ASAP methodology over 240 man months from May 2008 to February 2009 across JK Cement and involve custom development. After go-live, a service maturity model will ensure ongoing support and improvements.