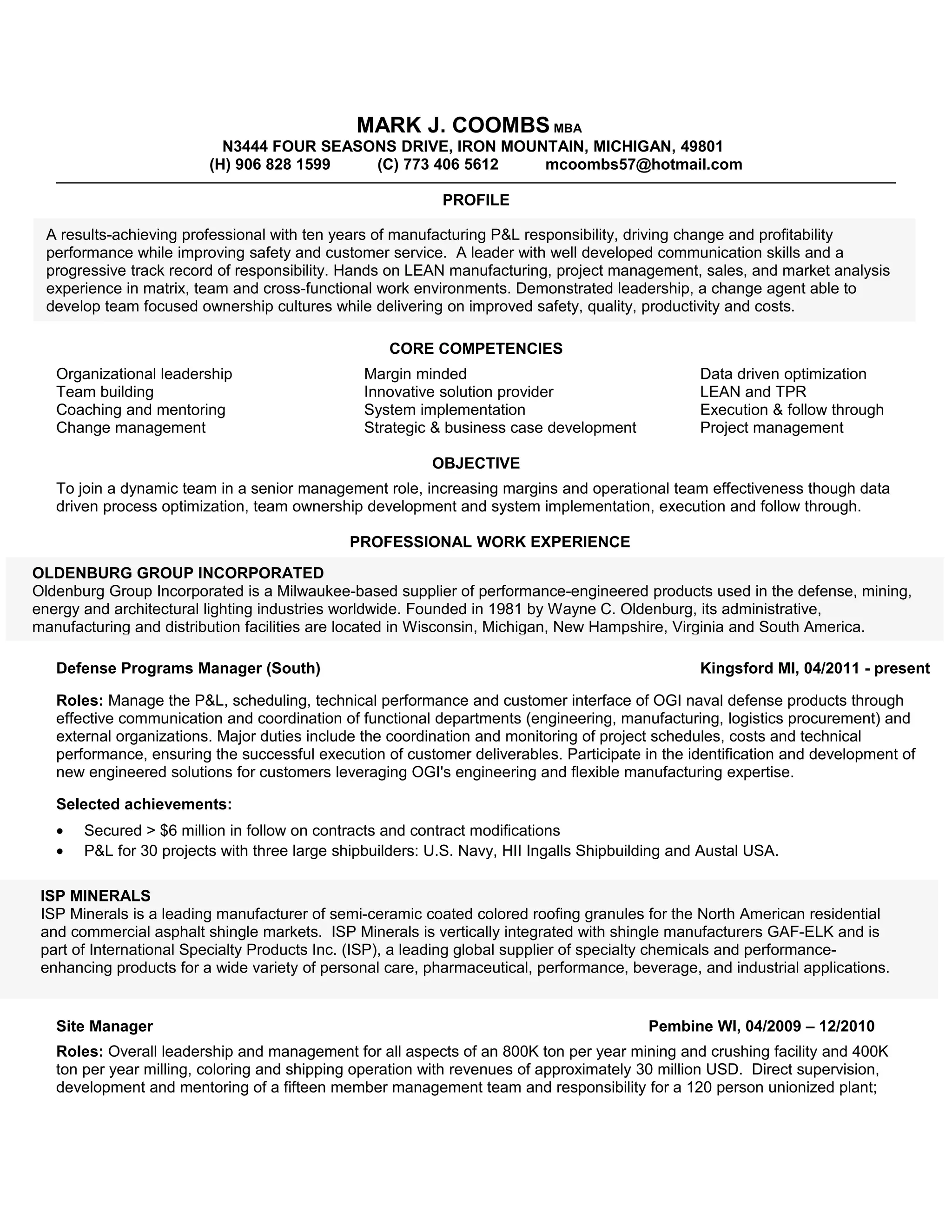

Mark Coombs has over 10 years of experience in manufacturing leadership roles, with a track record of improving safety, quality, productivity and costs. He currently manages the profit and loss, projects, and customer relationships for a defense manufacturing division. Previously he held site manager roles with responsibilities including production, safety, quality, costs and leadership of over 100 employees. He has an MBA from Purdue University and supplementary training in areas including leadership, negotiation, root cause analysis, and manufacturing systems.