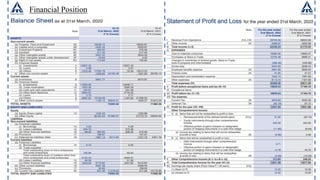

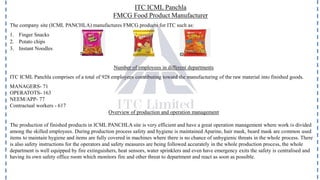

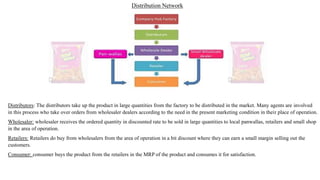

ITC is a diversified company established in 1910 with businesses in FMCG, hotels, personal care, paperboards, and stationary. It has products available in 6 million retail outlets and employs over 36,500 people across India. The company was ranked as India's most admired company in a survey. ITC has a strong foundation in consumer insights, R&D, product development, distribution networks, and human resources. It is a leading FMCG marketer and market leader in paperboard and packaging. The summary discusses ITC's vision, mission, values and provides an overview of its financial position and SWOT analysis.