Embed presentation

Downloaded 882 times

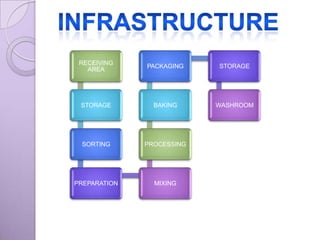

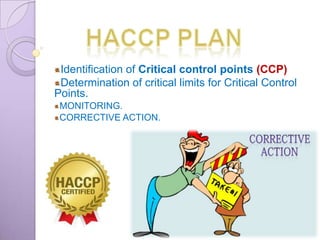

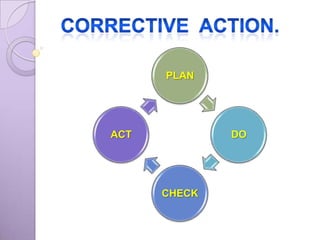

This document outlines the key elements of a food safety management system according to ISO 22000:2005. It discusses identifying, evaluating, and controlling food safety hazards. It also covers management responsibility, resource management, critical control points, verification, and continual improvement of the food safety management system. The overall goal is to plan and realize safe food products by identifying and controlling biological, chemical, and physical hazards and cross-contamination risks at all stages of production.