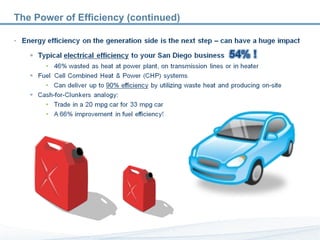

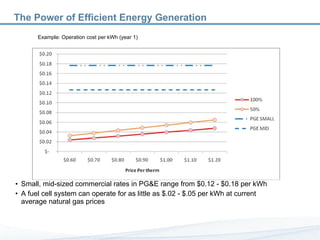

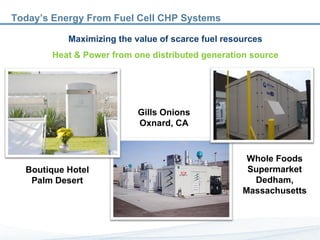

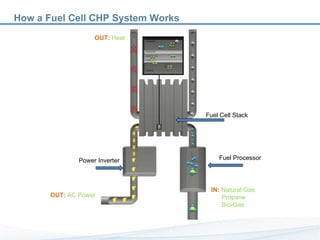

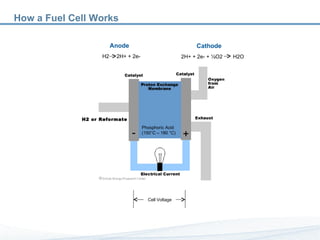

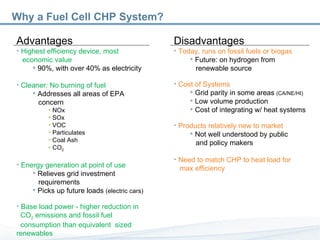

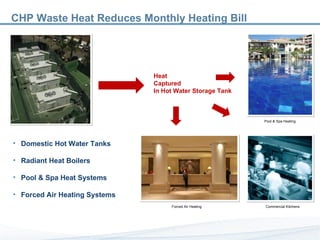

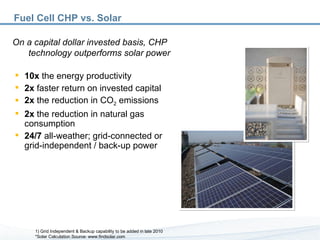

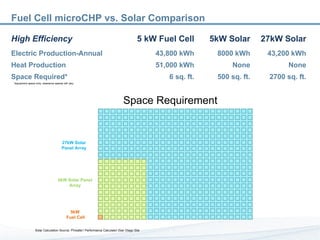

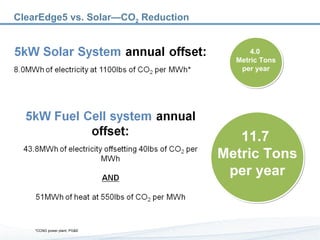

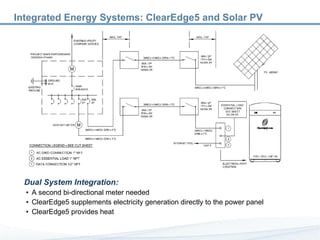

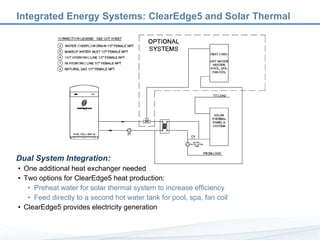

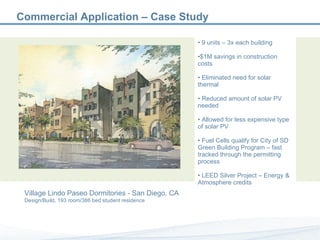

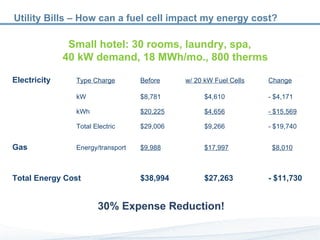

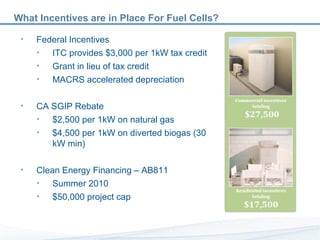

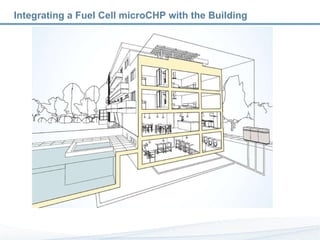

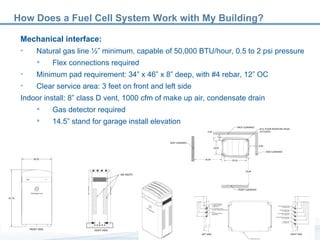

The document summarizes the benefits of stationary fuel cell systems for commercial real estate. Fuel cells provide clean, efficient distributed energy generation that can significantly reduce energy costs and carbon emissions compared to grid power. They operate at a lower cost per kWh than utility rates and can provide both electricity and heat for buildings. Various incentives are available to support the installation of fuel cell CHP systems.

![ClearEdge Power LEADING THE SMART ENERGY REVOLUTION Contact Info: Ryan Stepp, Business Development (805) 340-3626 [email_address]](https://image.slidesharecdn.com/irempresentation-final-100510124949-phpapp01/85/Irem-presentation-final-36-320.jpg)