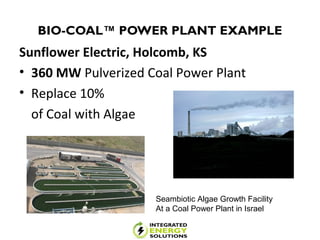

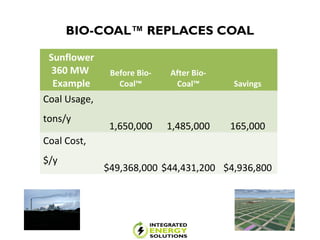

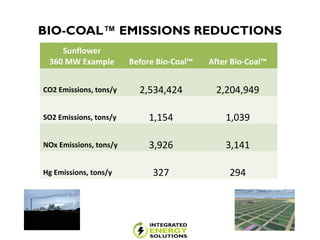

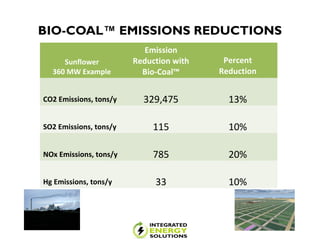

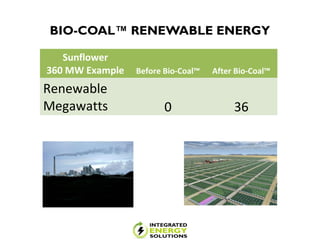

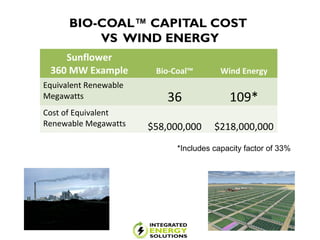

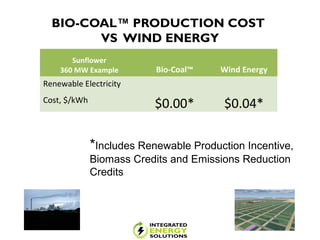

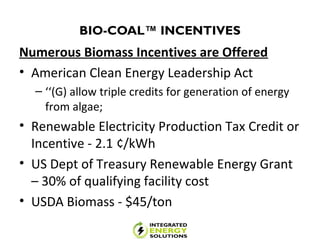

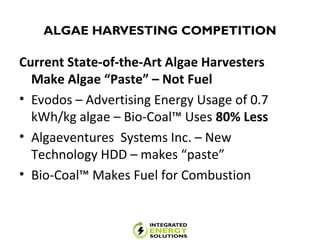

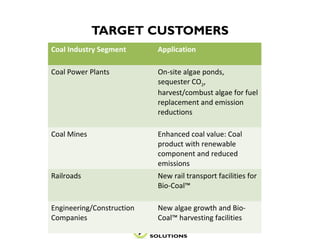

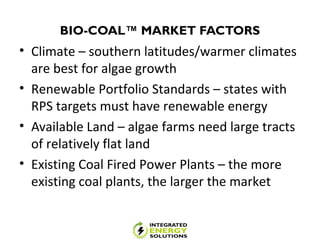

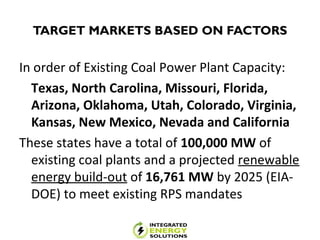

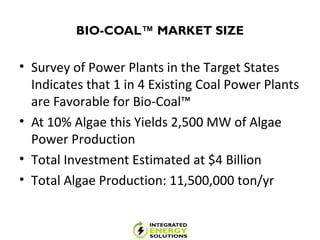

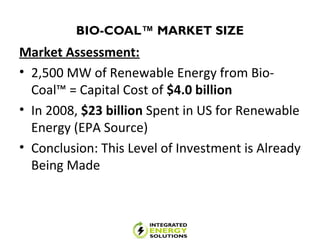

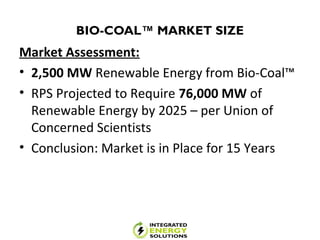

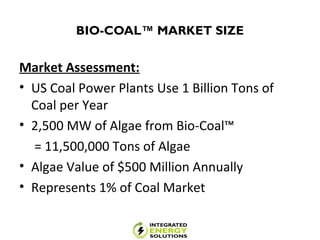

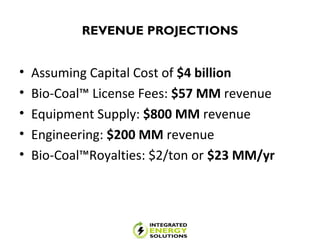

This document provides an overview of Integrated Energy Solutions LLC and their Bio-Coal technology for co-firing algae and coal at power plants. The technology involves cultivating algae, harvesting it, and mixing it with coal for combustion. It can generate renewable energy at existing coal plants while reducing emissions. The company projects developing a $4 billion market by installing the technology at 2500 MW of capacity across favorable coal plant locations in the southern US.