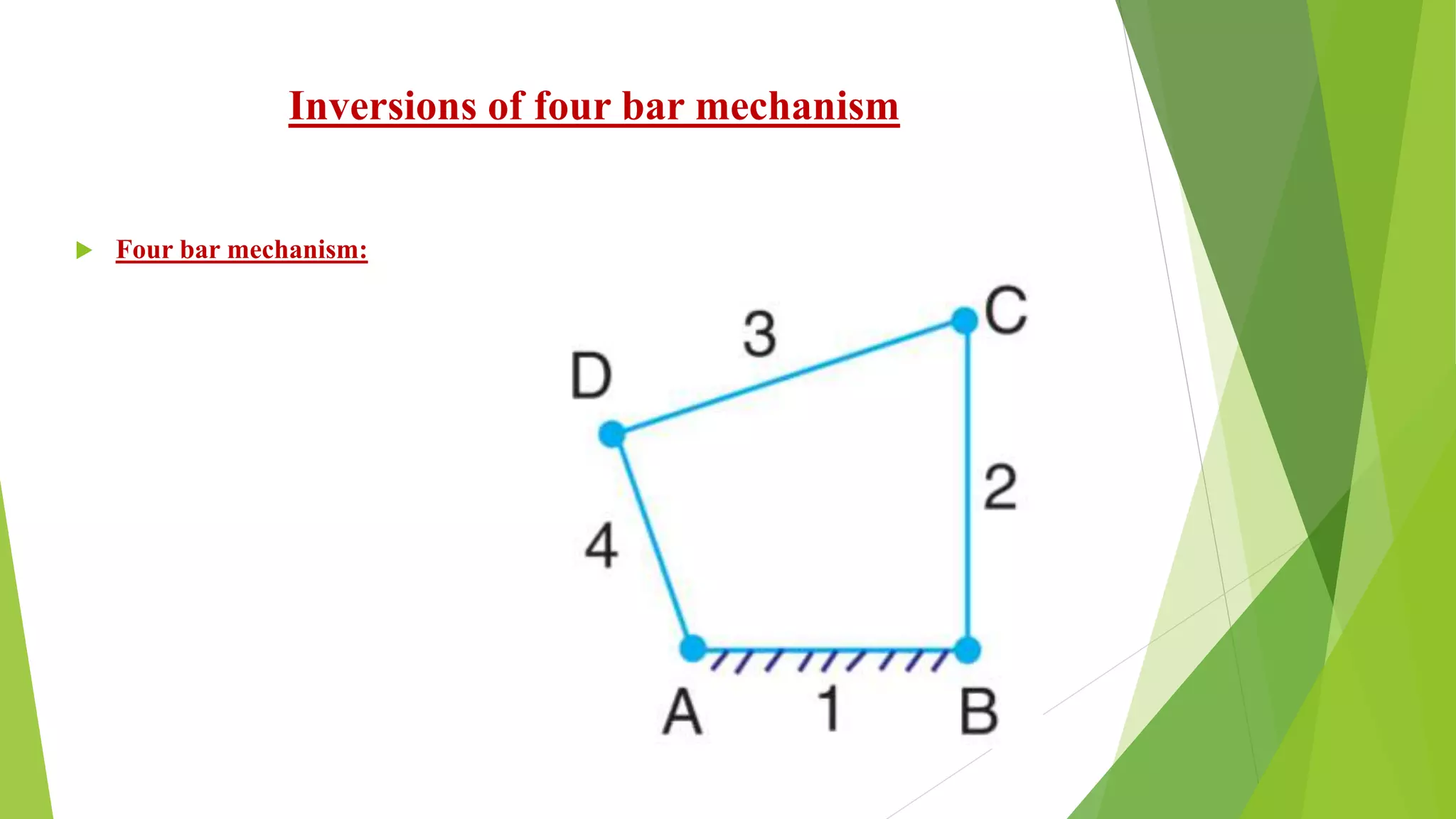

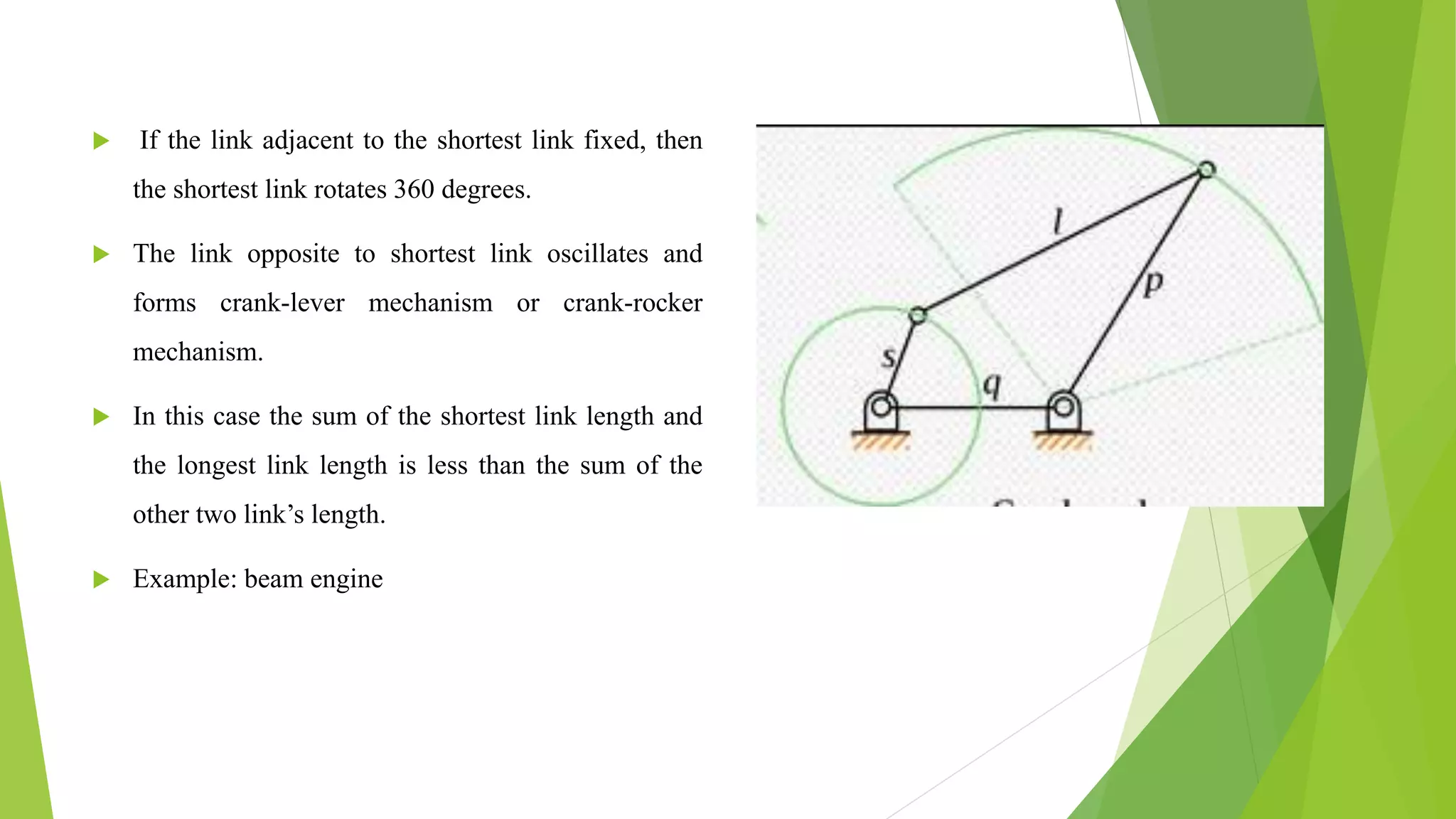

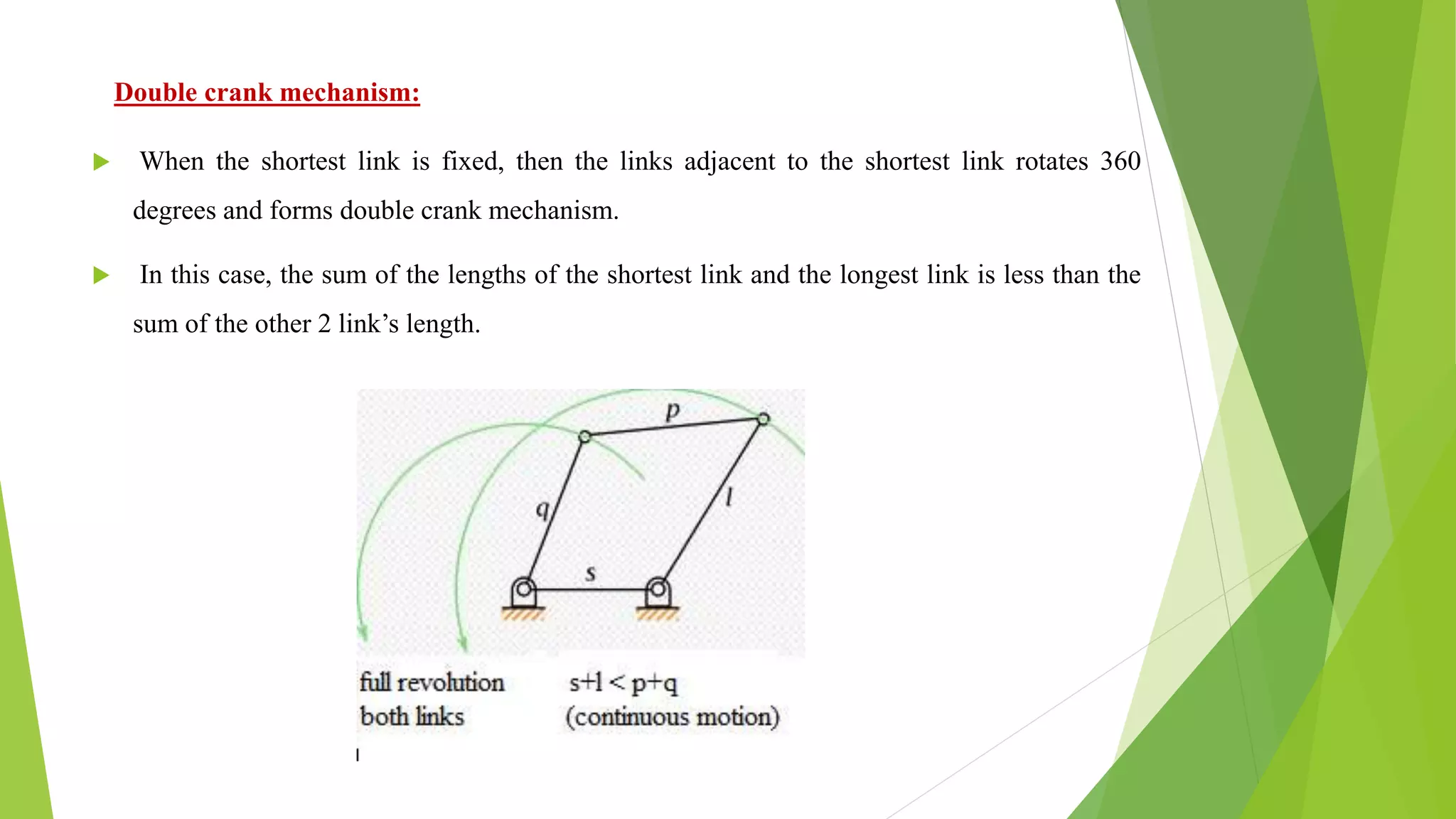

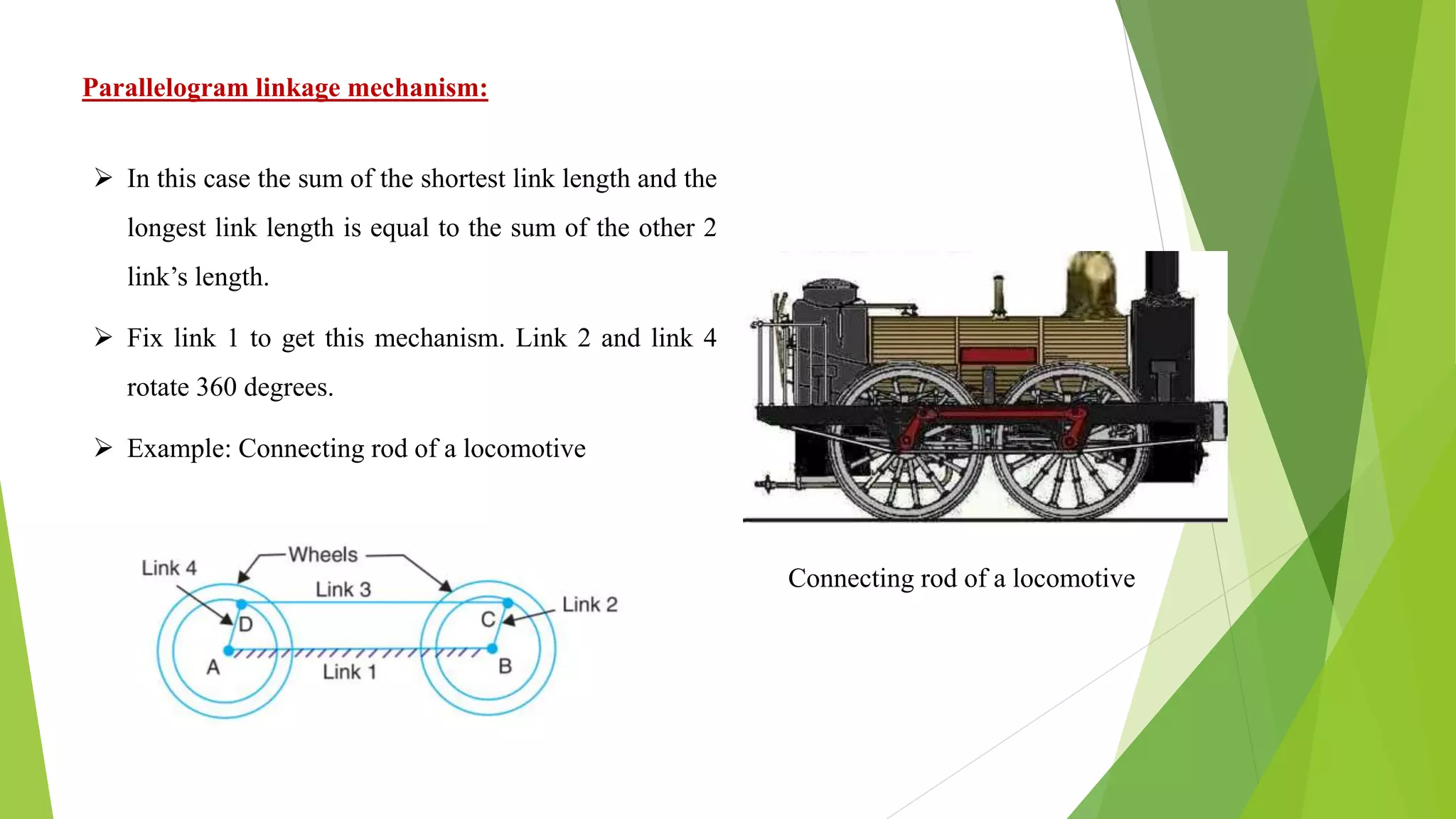

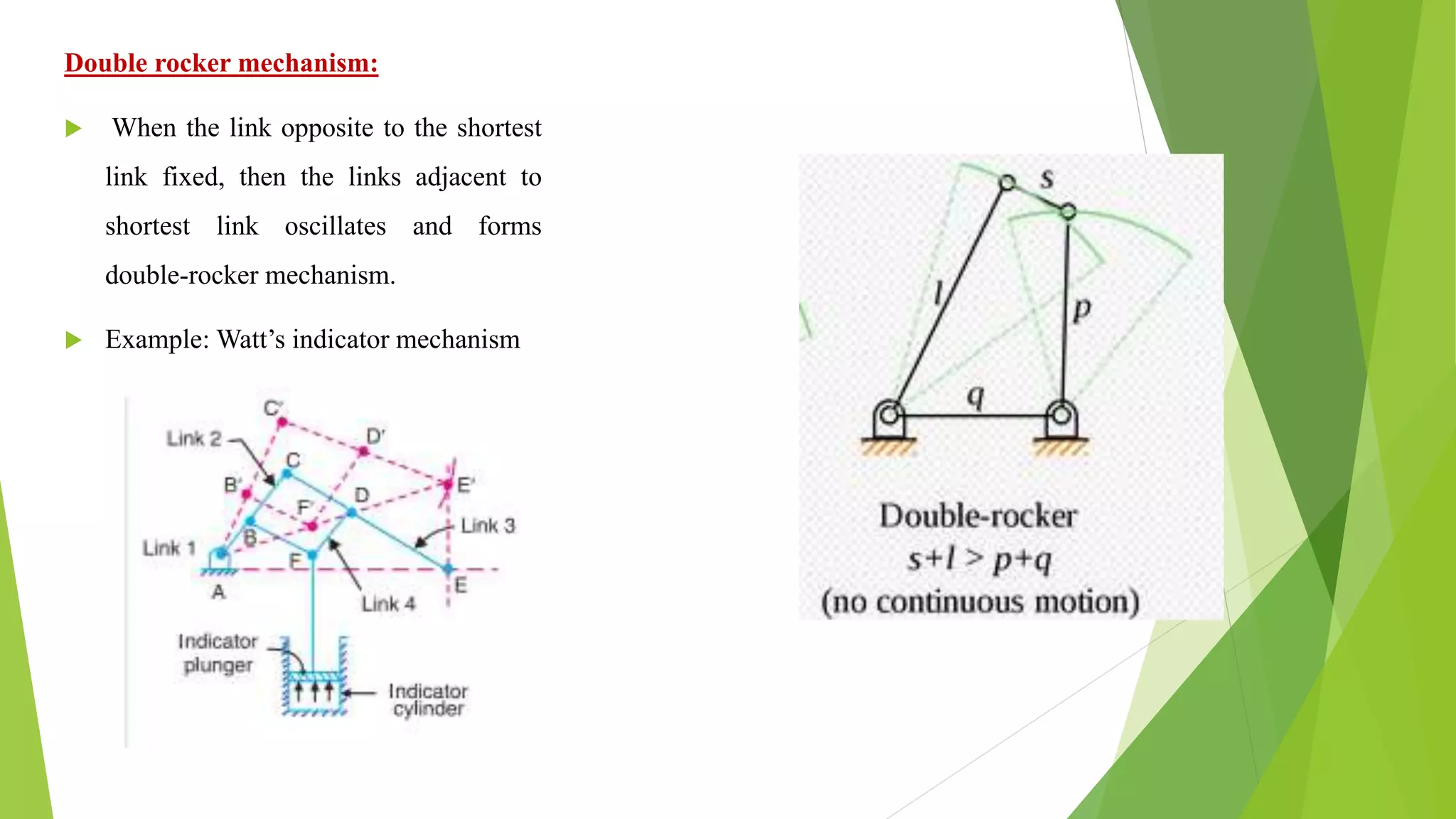

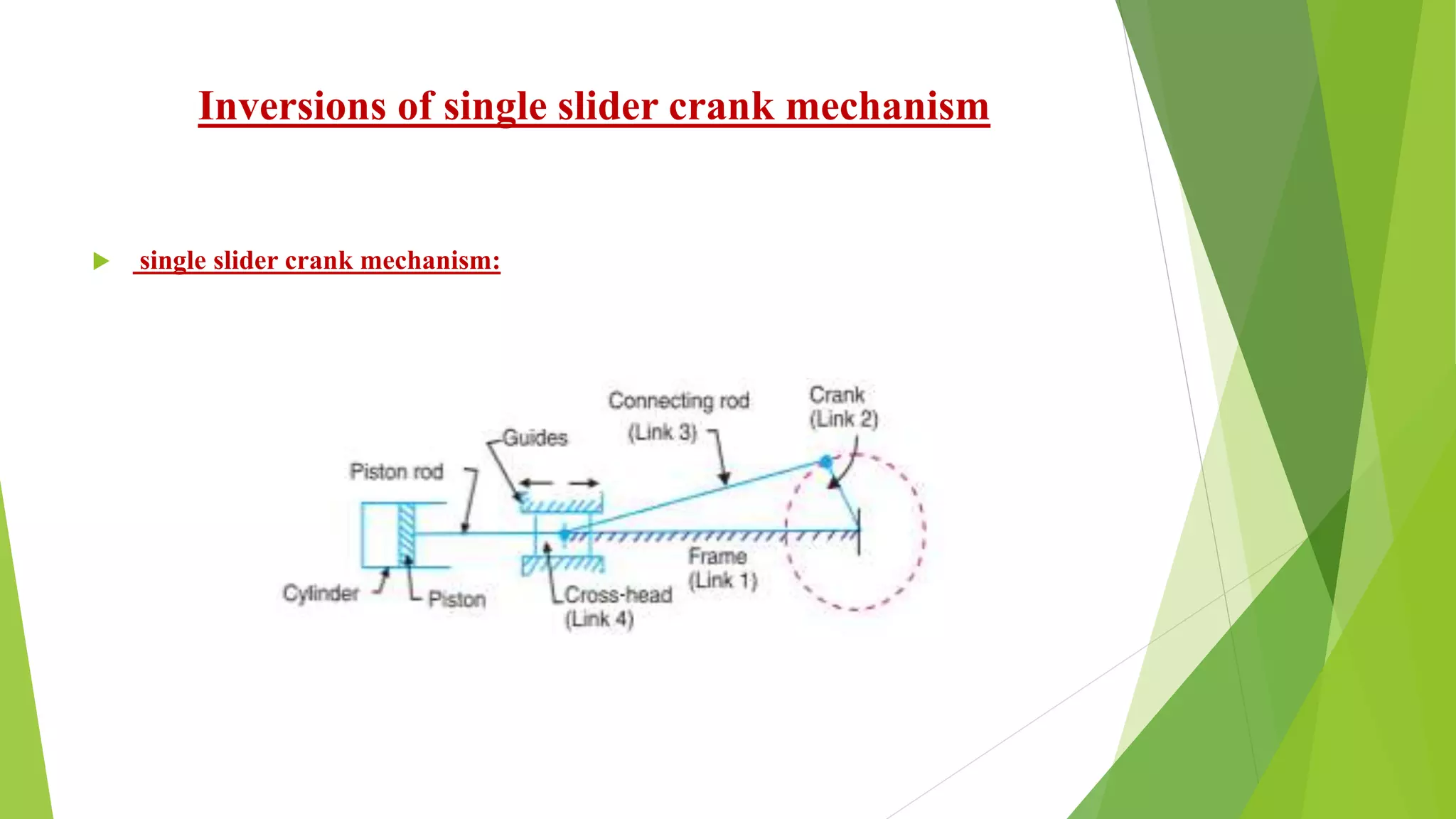

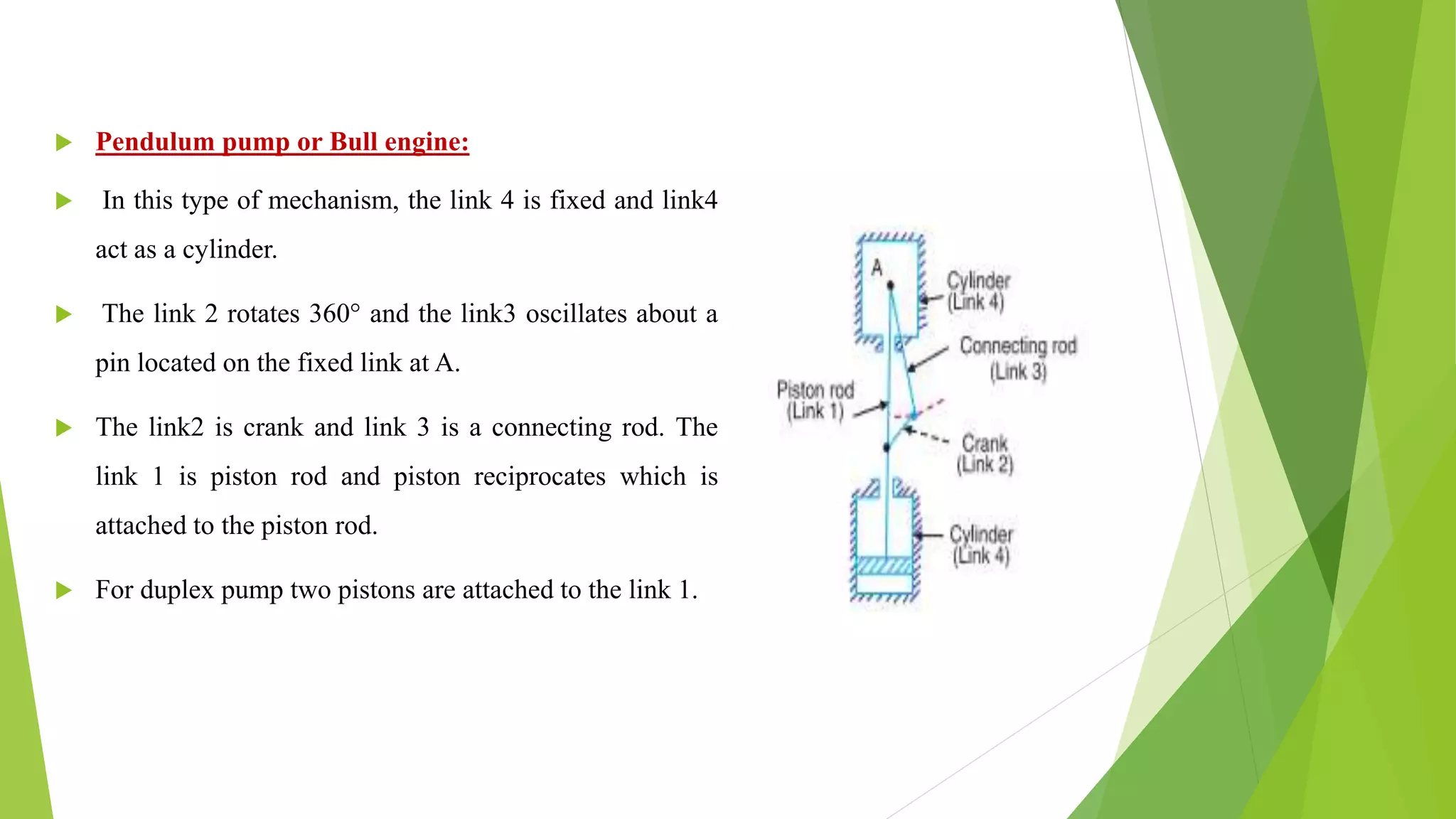

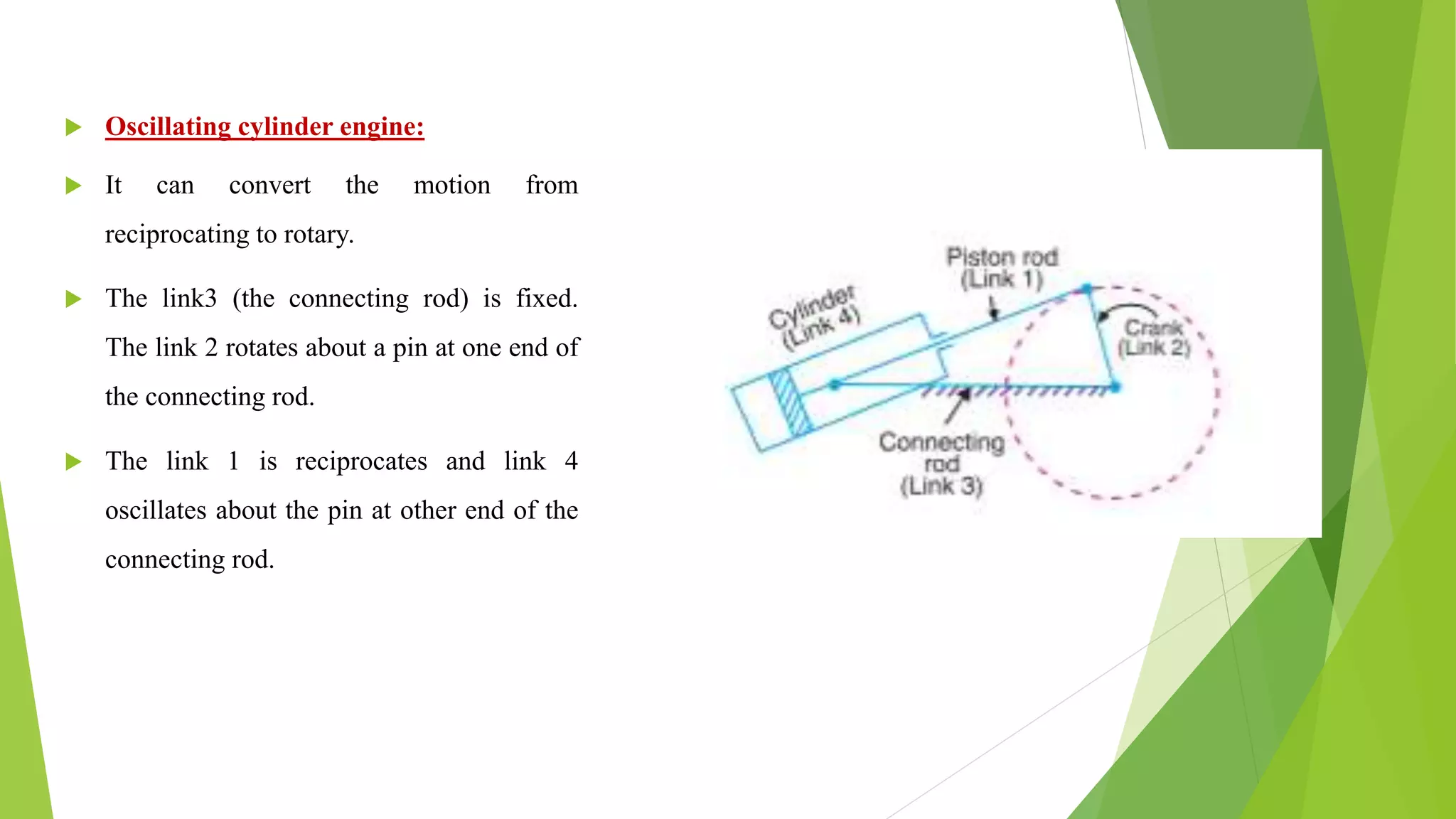

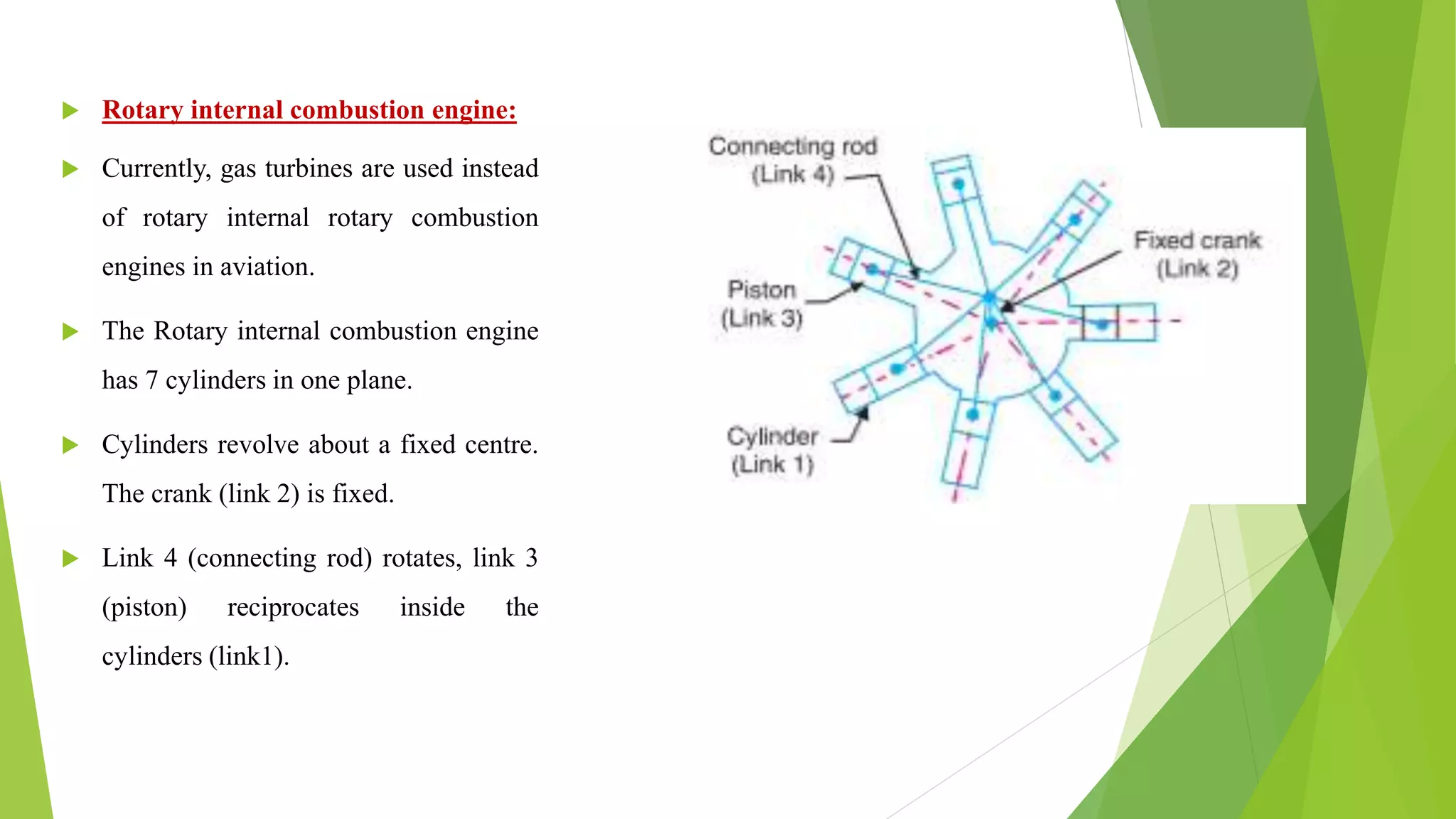

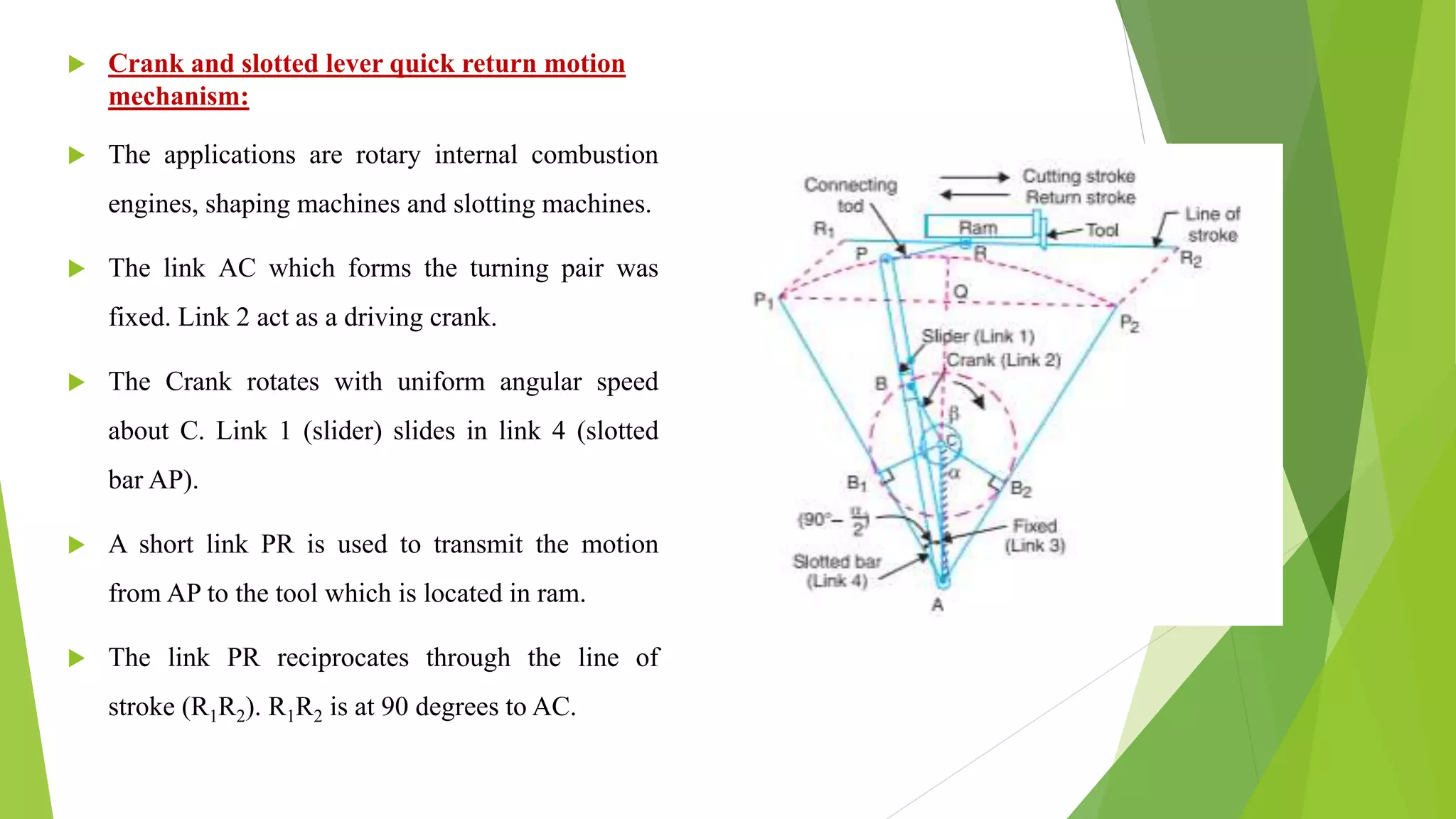

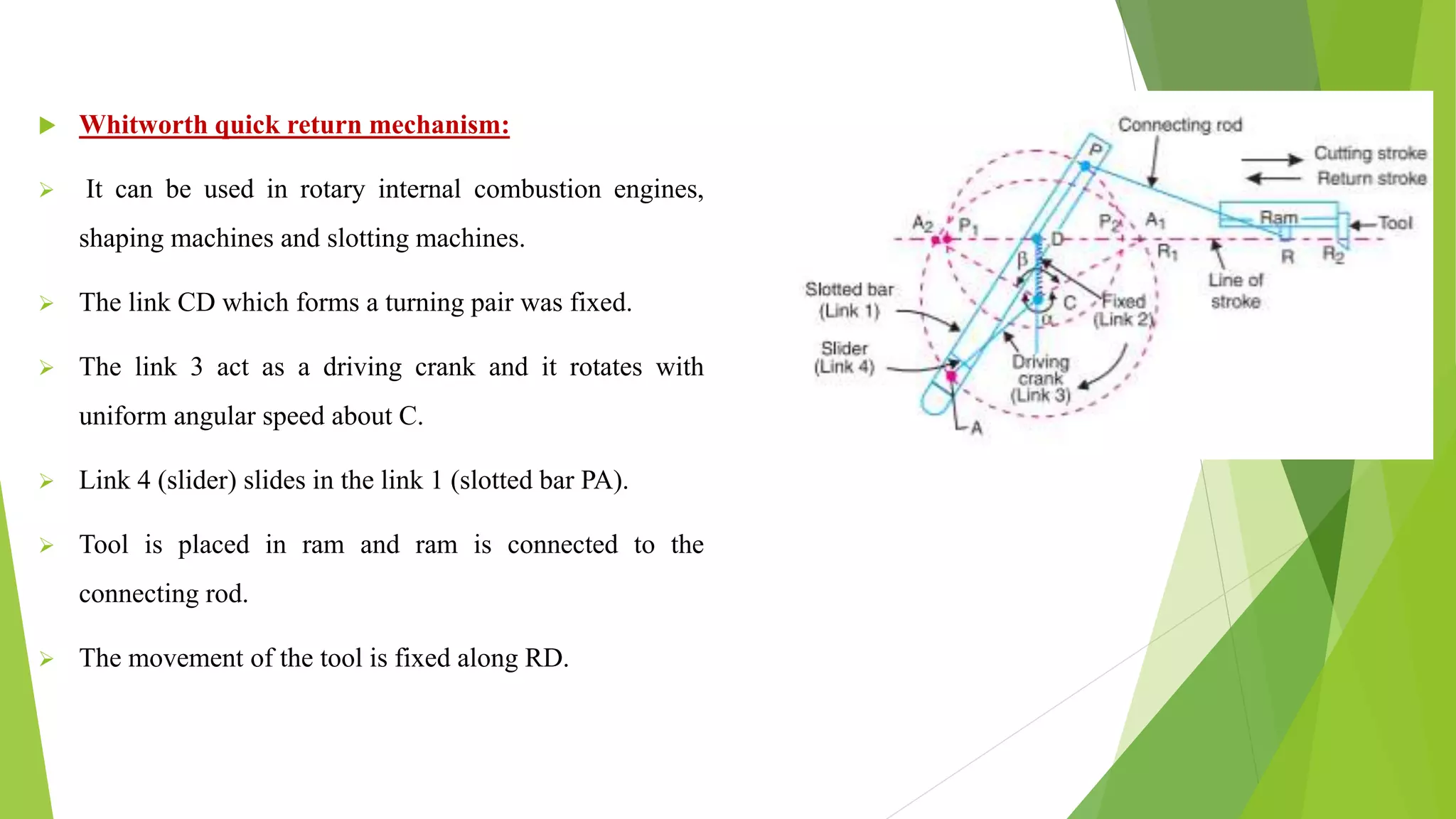

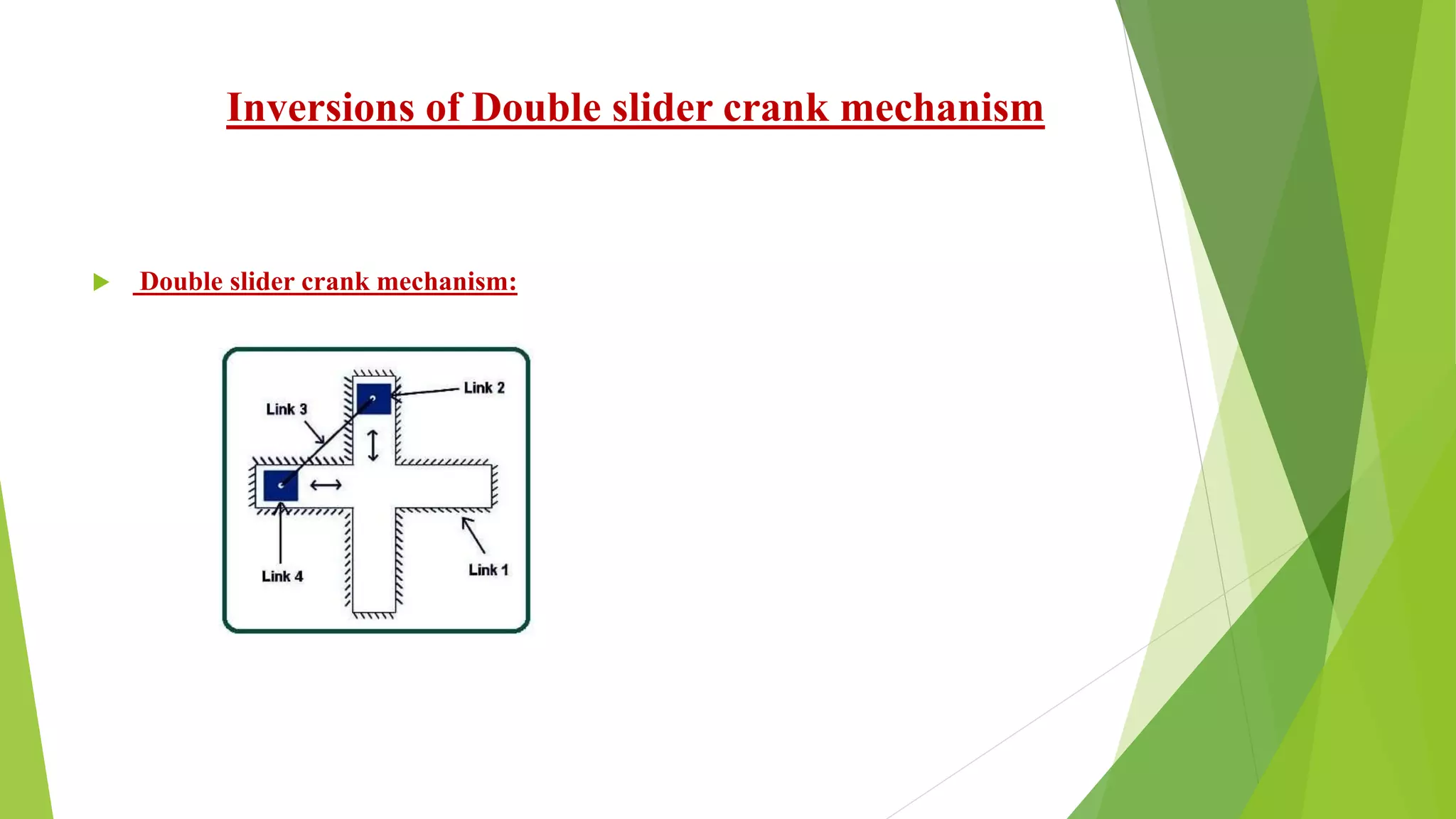

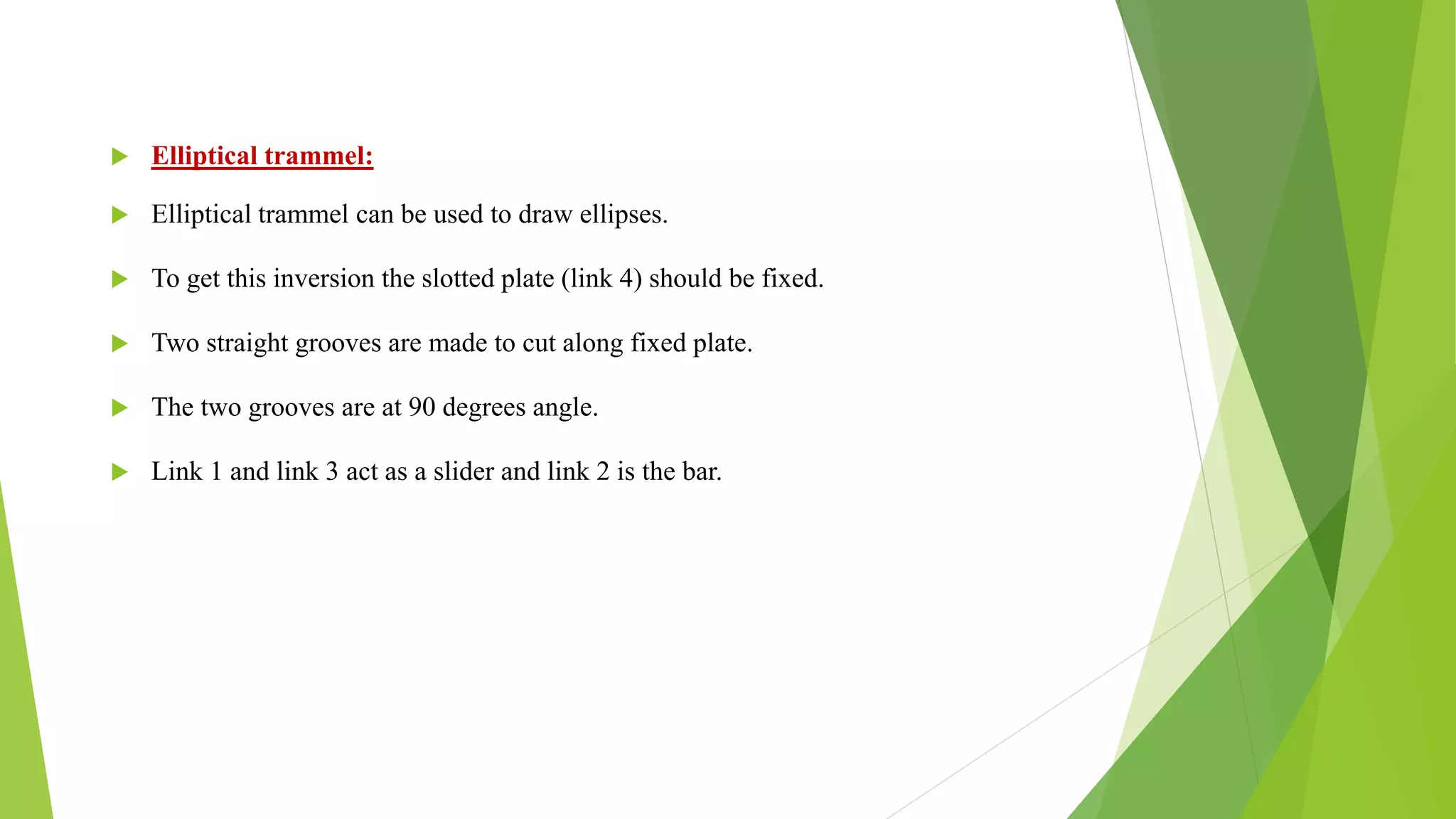

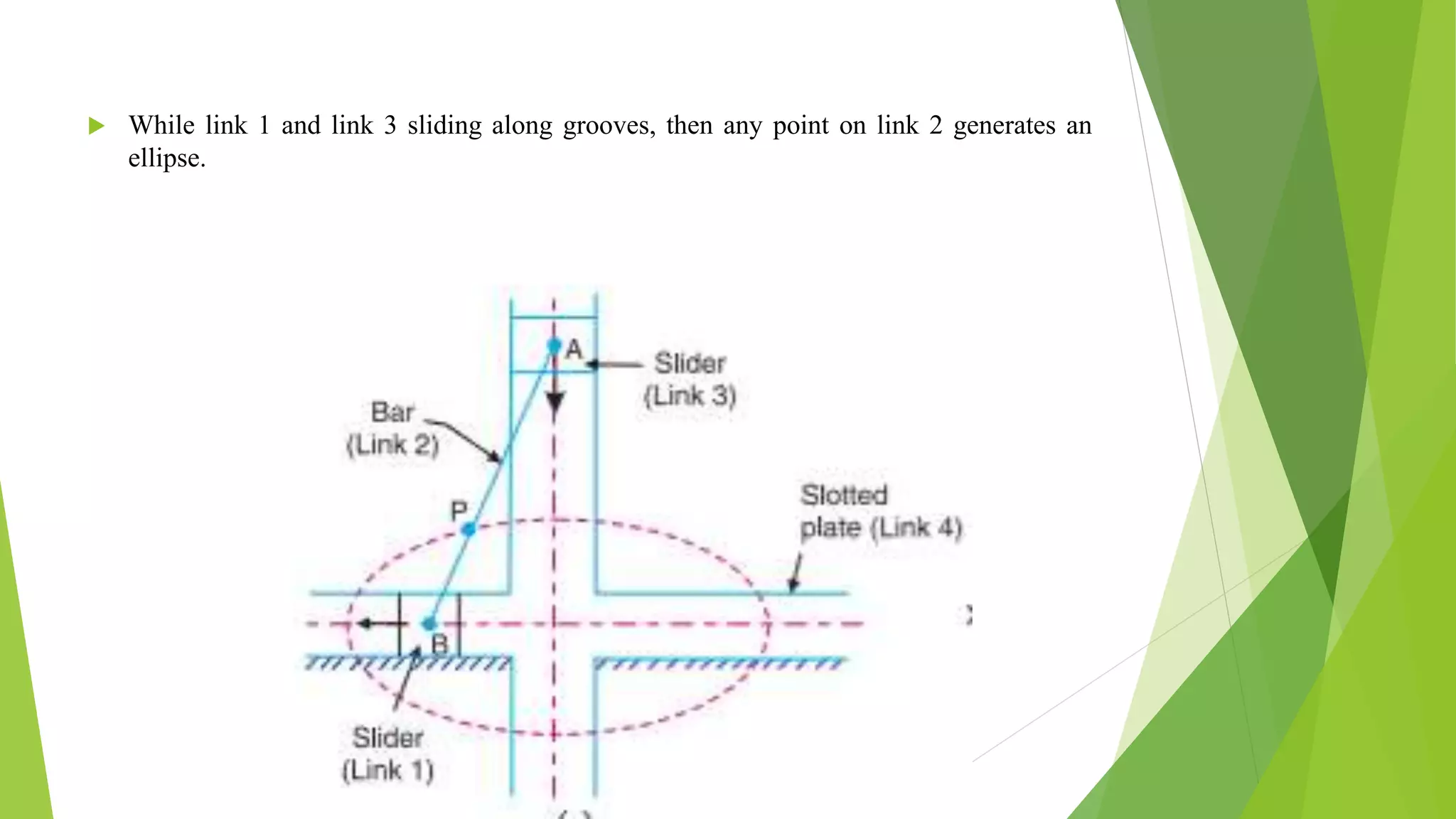

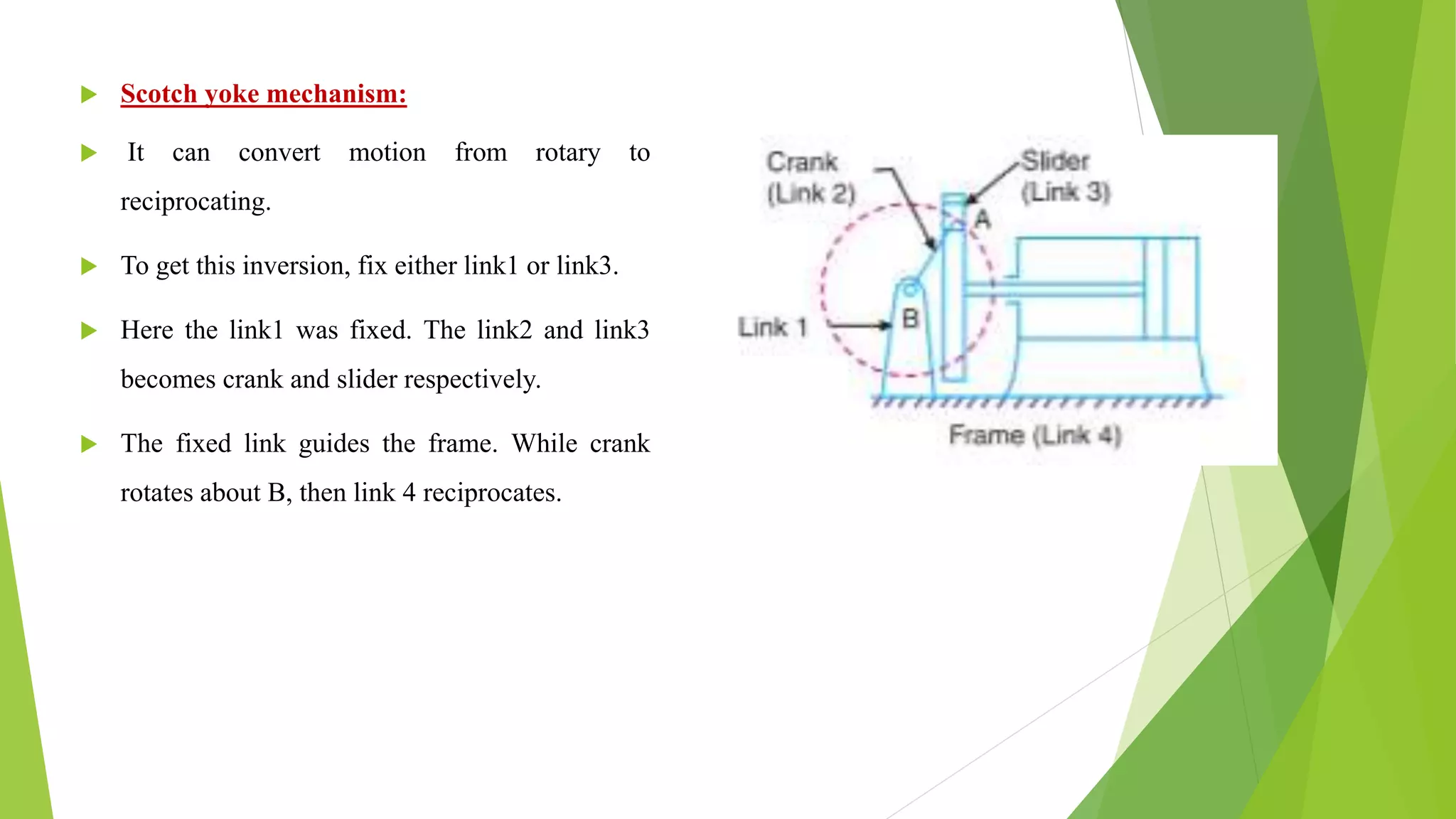

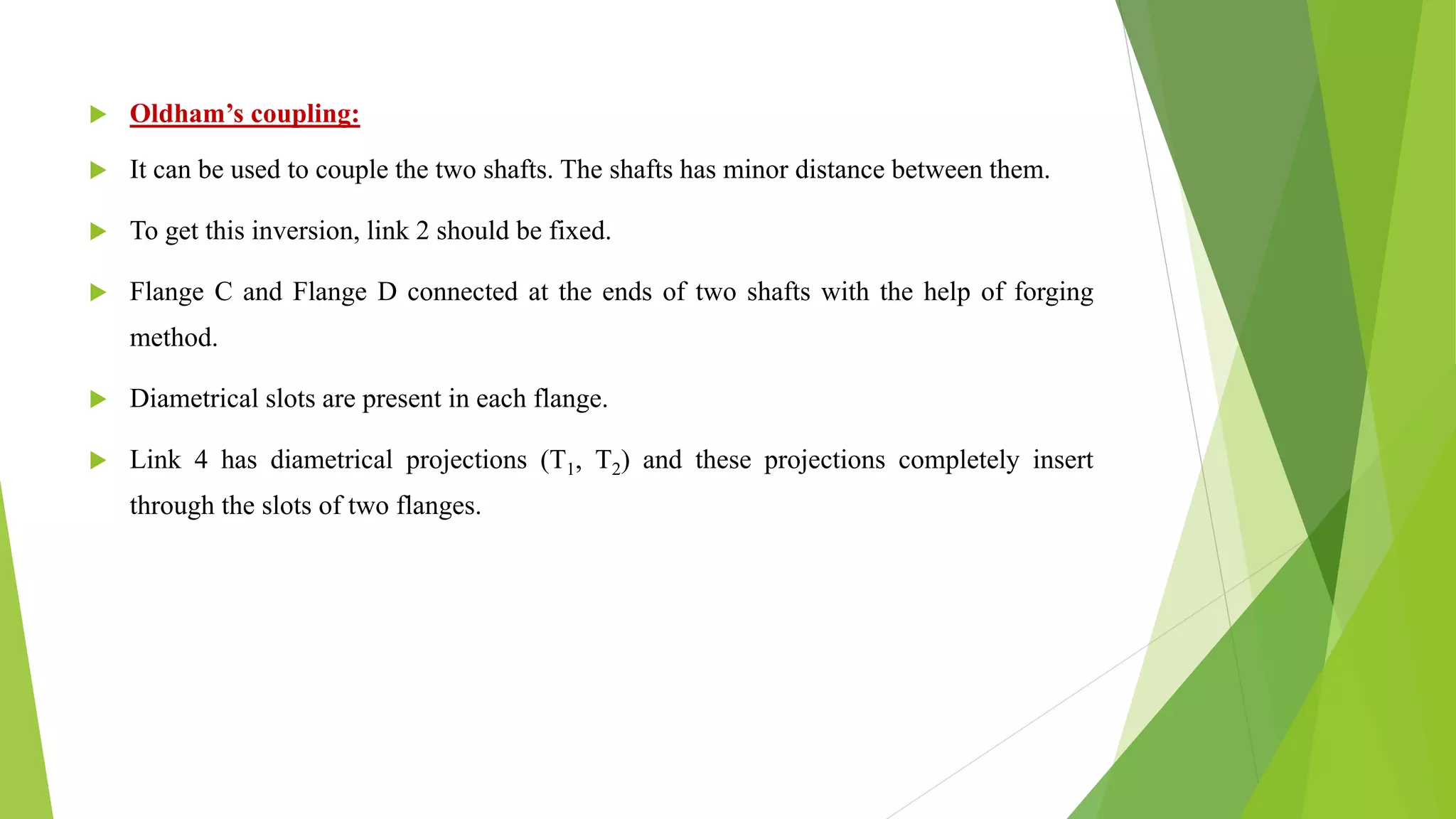

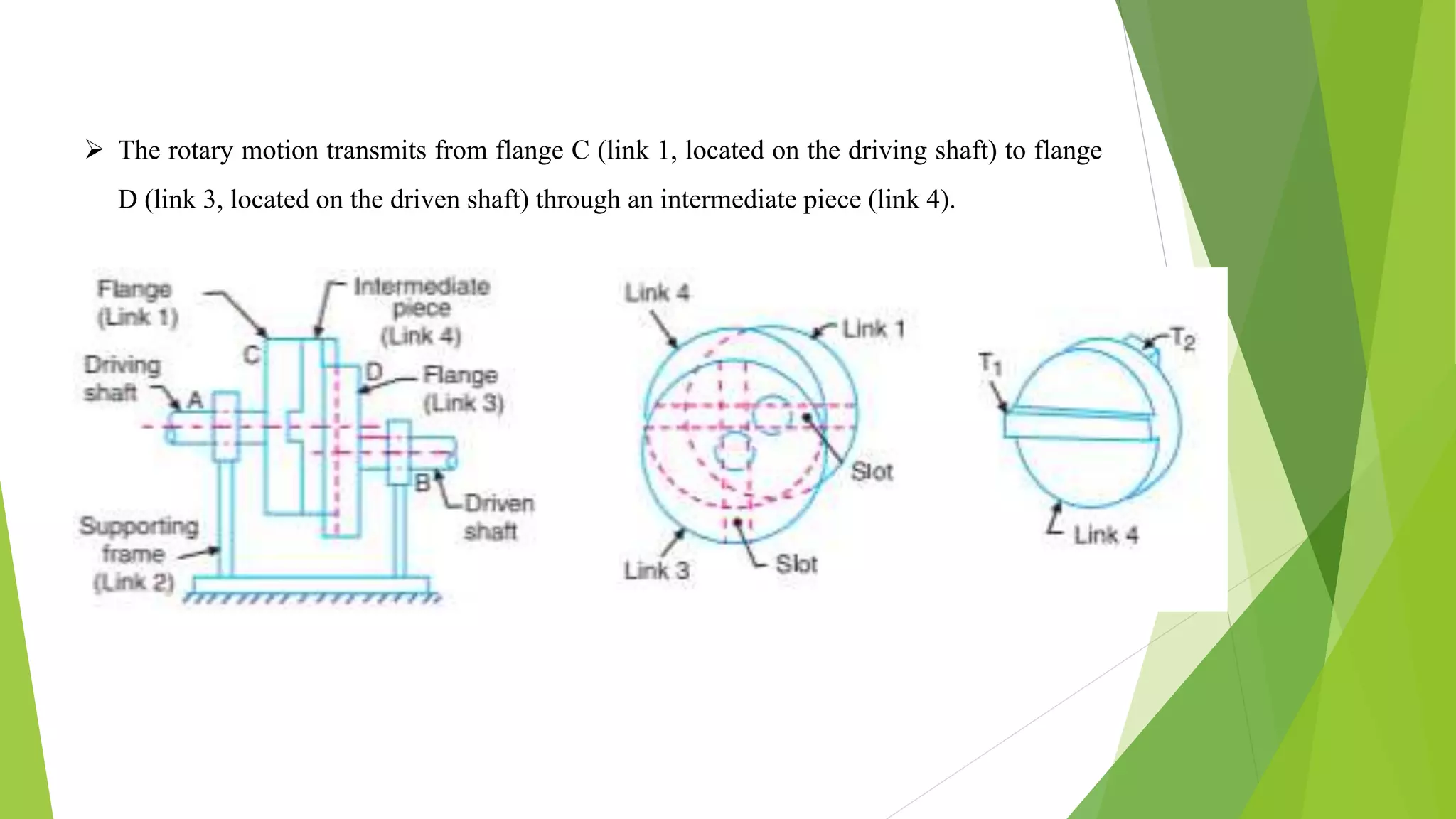

The document outlines a seminar on inversions of mechanisms and technical writing, focusing on various kinematic chains and their classifications. It details different mechanisms such as four-bar, single slider crank, and double slider crank mechanisms, explaining their components and operational principles. References are provided for further reading on the theory of machines.