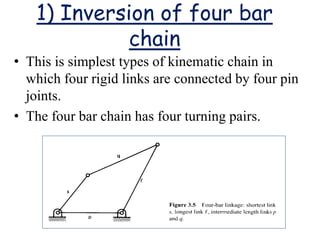

This document discusses the inversion of mechanisms. It begins by defining inversion of mechanisms as generating different mechanisms by fixing one link in a kinematic chain. It then discusses three types of inversions: 1) inversion of a four bar chain, which includes inverting links in a chain with four rigid links connected by four pin joints, 2) inversion of a single slider crank chain, which includes mechanisms like a pendulum pump or oscillating cylinder engine, and 3) inversion of a double slider crank chain, which includes mechanisms like an elliptical trammel or scotch yoke mechanism. Diagrams and examples are provided for each type of inversion.

![[a] Pendulum pump:

• When the sliding pair is

fixed, the mechanism is

known as pendulum pump.

• As the figure, link 2 (crank)

rotates, link 3 (connecting

rod) oscillates about a pin C

and the piston attached to

piston rod (link 1)

reciprocates in the cylinder.](https://image.slidesharecdn.com/inversions-230128090758-b7c9903c/85/Inversions-ppt-8-320.jpg)

![[b] Oscillating cylinder engine:

• In this mechanism link 3 is fixed. The link 2

rotates, the link 1 (piston rod) reciprocate and

the link 4 (cylinder) oscillate about a pin A.](https://image.slidesharecdn.com/inversions-230128090758-b7c9903c/85/Inversions-ppt-9-320.jpg)

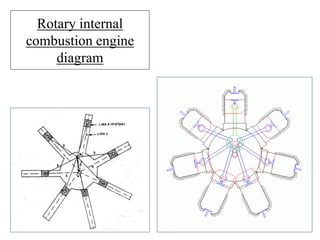

![[c] Rotary internal combustion engine:

• This mechanism is used in multi cylinder

engine.

• It consists of several cylinders in one plane and

all revolve about fixed center O, as shown

figure.

• The crank (link 2) is fixed.

• When the connecting rod (link 4) rotates, the

piston (link 3) reciprocates inside the cylinder

forming link 1.](https://image.slidesharecdn.com/inversions-230128090758-b7c9903c/85/Inversions-ppt-10-320.jpg)

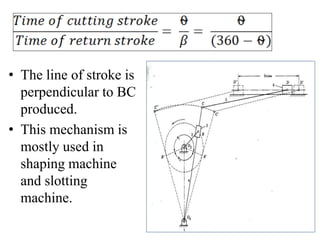

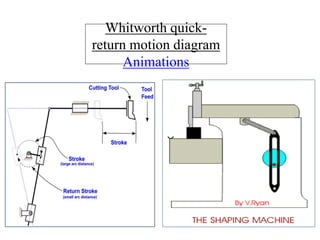

![[d] Crank and slotted lever quick-

return motion mechanism:

• In this mechanism, link 1 is slider which slide in

slotted lever.

• The slotted lever is link 4. link 3 is fixed where

the center of crank attached.

• Link 2 is crank which rotates in clockwise

direction.

• Link 4 is the arm which oscillates about point C.

• A short link DE transmits the motion with

reciprocates with the tool along line of stroke.](https://image.slidesharecdn.com/inversions-230128090758-b7c9903c/85/Inversions-ppt-12-320.jpg)

![3) Inversion of Double

slider crank chain

• There are four type of inversion of double

slider crank chain mechanism as:

[a] Elliptical trammel

[b] Scotch yoke mechanism

[c] Oldham’s coupling

[d] Donkey Pump](https://image.slidesharecdn.com/inversions-230128090758-b7c9903c/85/Inversions-ppt-15-320.jpg)

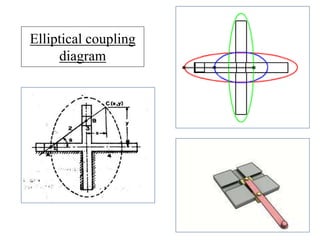

![[a] Elliptical Coupling:

• In this mechanism two slots are cut at right

angles in a plane which is fixed.

• Two blocks slide in these two slots.

• Two sliding blocks form two links, which are of

sliding type.

• Two sliding blocks are connected by one link.

• Point on this link at anywhere generate ellipse,

when any ne blocks slides in its slot.](https://image.slidesharecdn.com/inversions-230128090758-b7c9903c/85/Inversions-ppt-16-320.jpg)

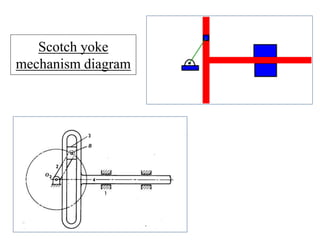

![[b] Scotch yoke mechanism:

• This mechanism converts rotary motion to

reciprocating motion (simple harmonic motion).

• It is used in vibration exciter to produce vibration

of desired frequency.

• This Chain has two revolute pairs and two

prismatic pairs.

• The first inversion is with a link with revolute

pair and prismatic pair is fixed.](https://image.slidesharecdn.com/inversions-230128090758-b7c9903c/85/Inversions-ppt-18-320.jpg)

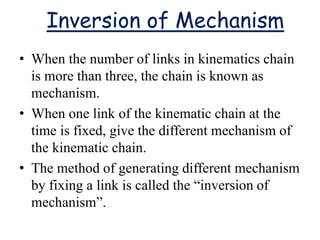

![[c] Oldham’s Coupling:

• When the distance between two shaft axes is

small, motion is transmitted by oldham’s

coupling.

• At the end of both the shafts there is flanges.

• This flange forms links 2 and 4.

• Both this links forms a turning pair with link 3.

• There is a diametrical slot on both the flange.

• An intermediate piece have a diametrical outside

tongues at right angle on both sides.](https://image.slidesharecdn.com/inversions-230128090758-b7c9903c/85/Inversions-ppt-20-320.jpg)