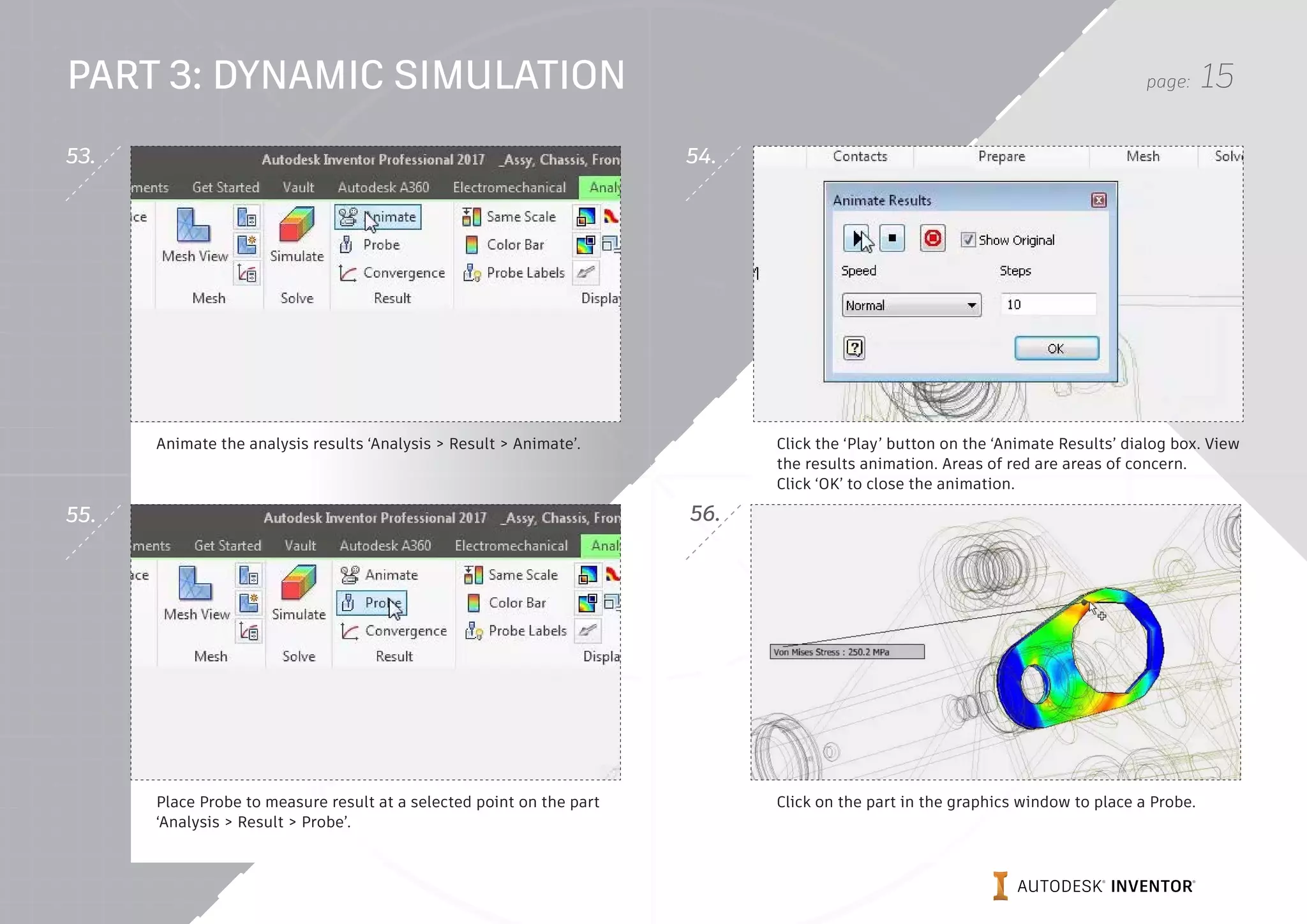

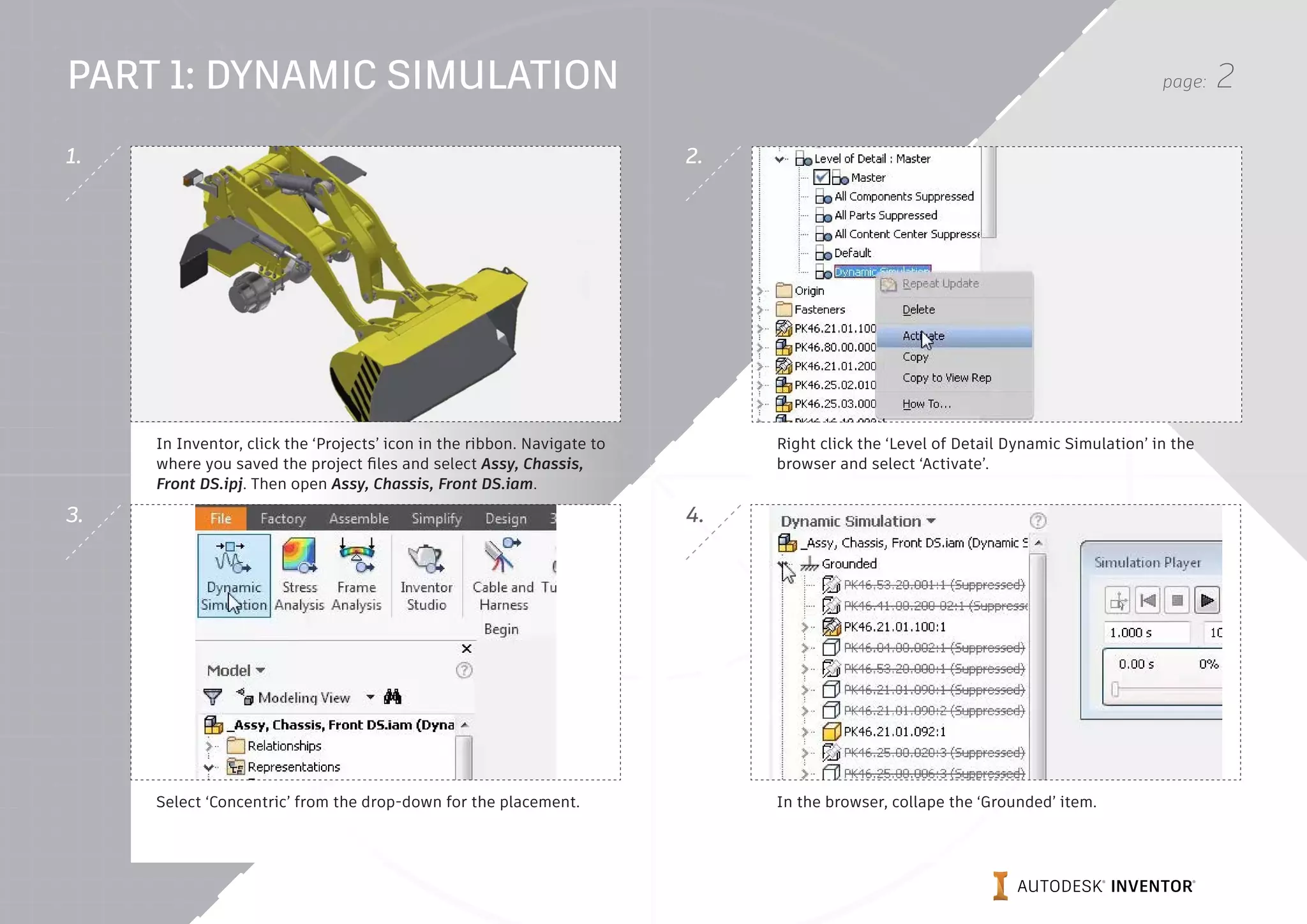

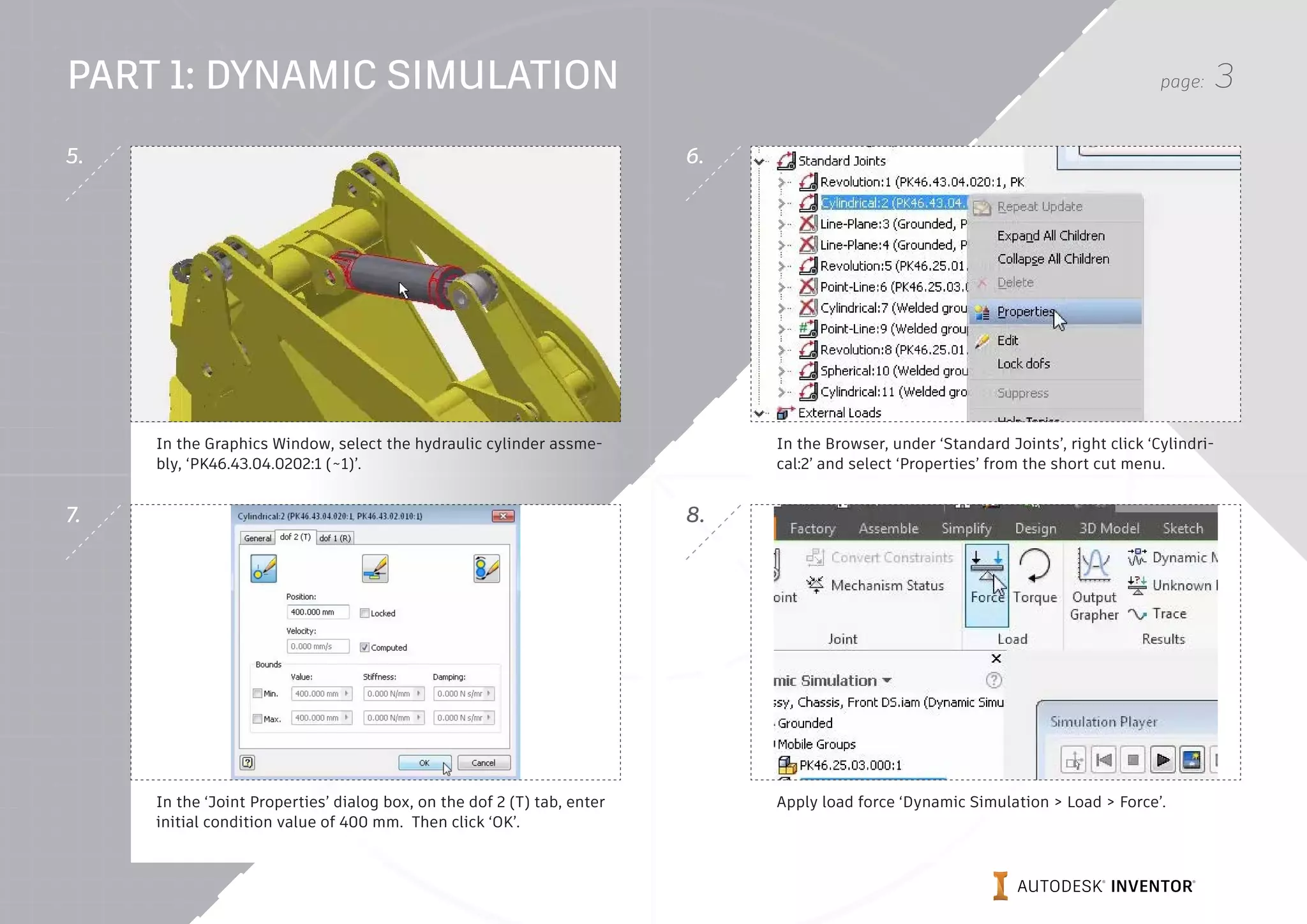

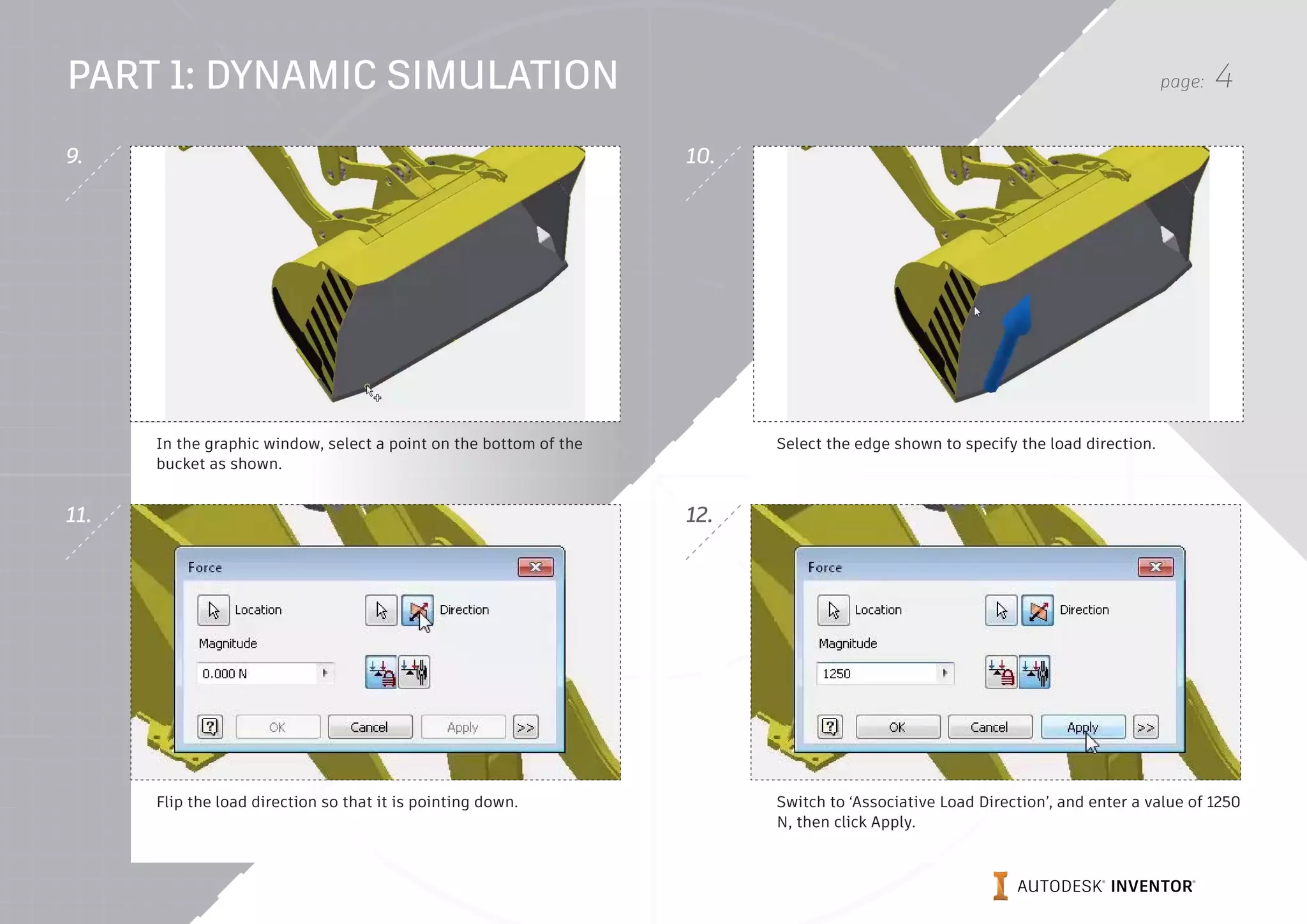

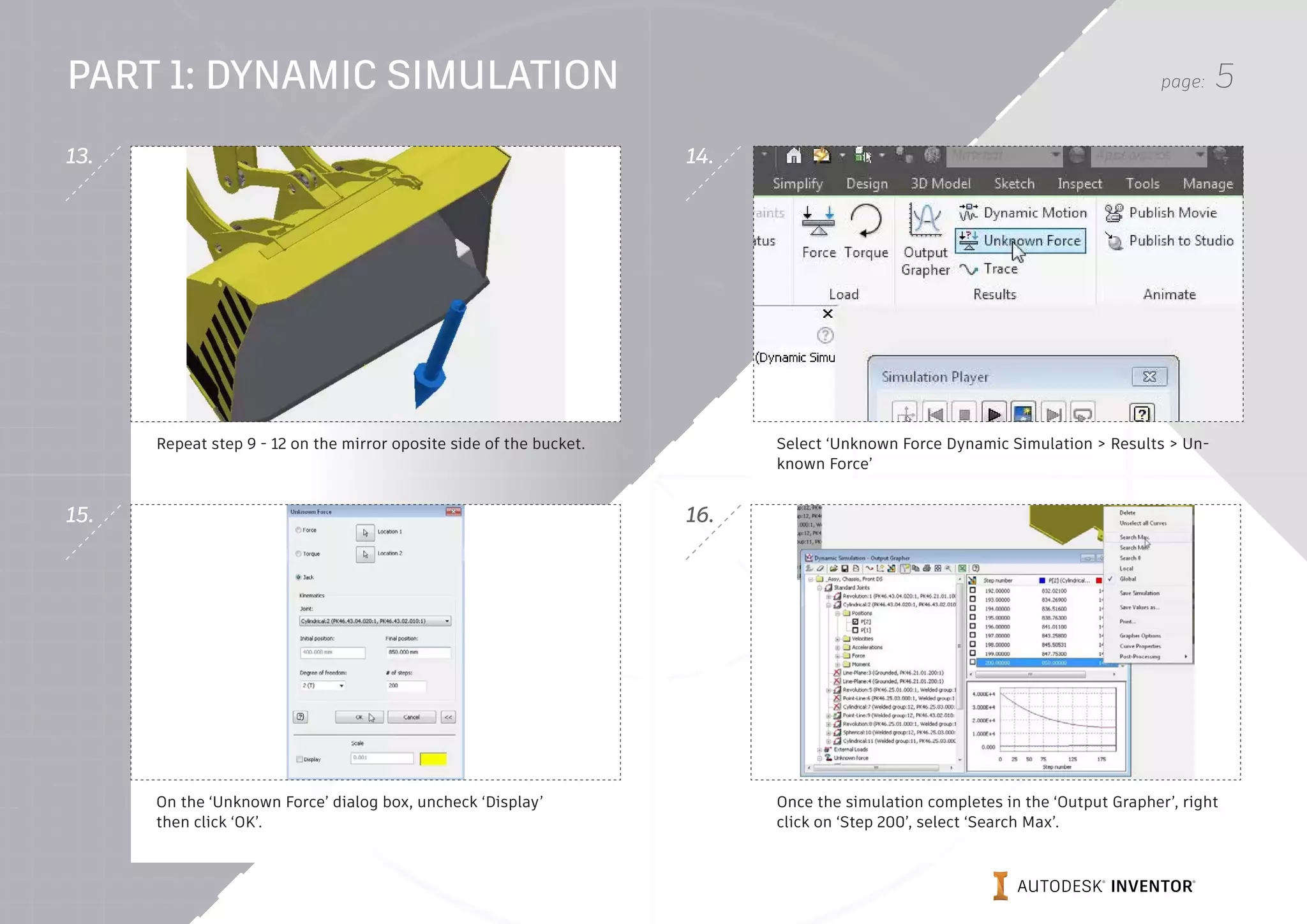

The document provides instructions for using Autodesk Inventor to perform dynamic simulations on a front loader assembly. It describes how to activate the dynamic simulation environment, apply forces to simulate hydraulic cylinders and bucket loading, export the simulation to stress analysis, mesh parts, run the stress analysis simulation, and view displacement and stress results. The goal is to analyze stresses on the assembly under simulated loading conditions.

![page: 10

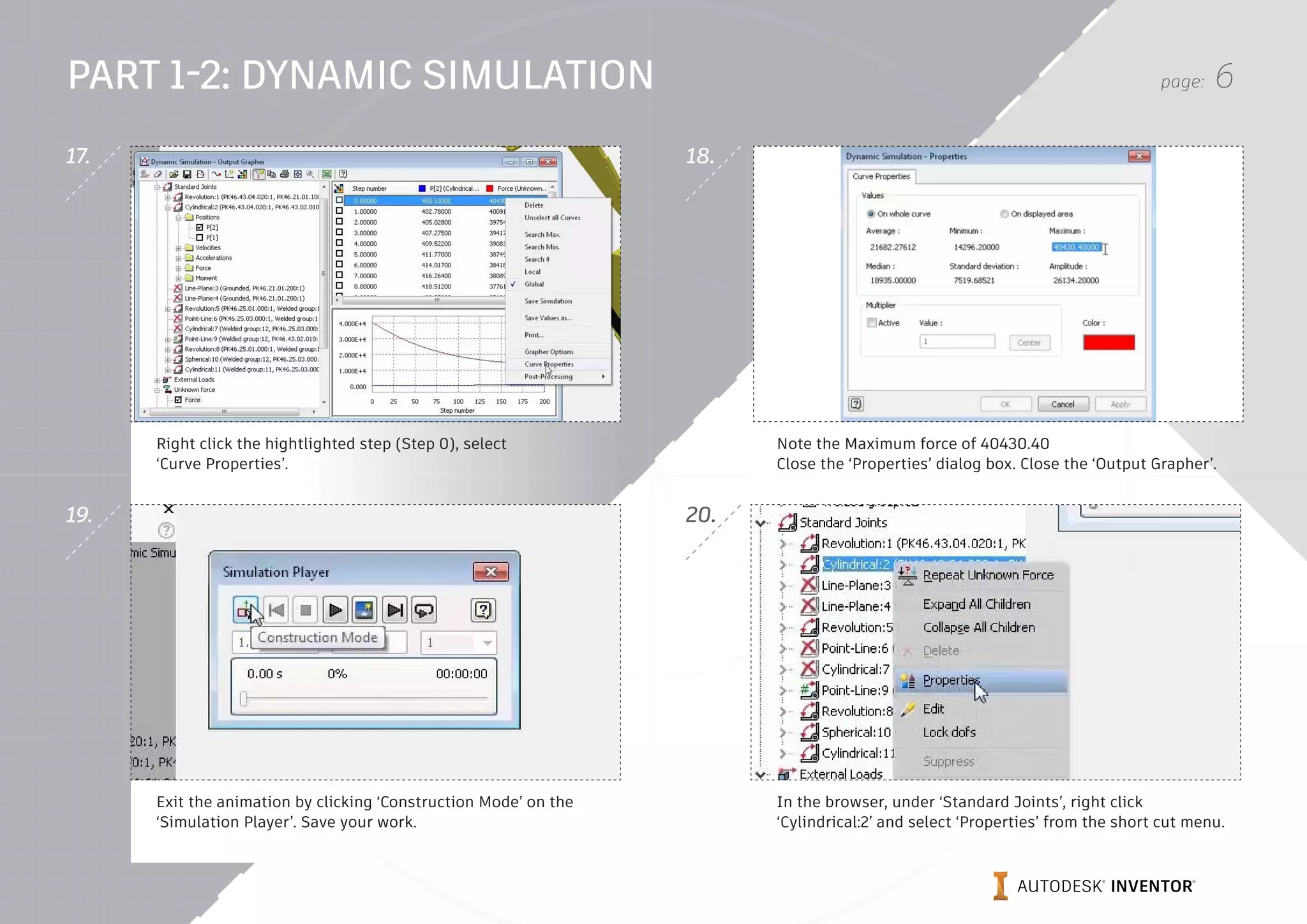

On the ‘Output Grapher’, expand ‘Joint Revolution:14’, then

expand the Force folder, then check ‘On Force’.

On the ‘Output Grapher’, under ‘Joint Cylindrical:2’, uncheck

‘P[2]’.

On the ‘Output Grapher’, check ‘Time Step 1.00000’ to export it. On the ‘Output Grapher’, double click on the graph at the ‘0.5

time mark’.

34.

36.

33.

35.

PART 2: DYNAMIC SIMULATION](https://image.slidesharecdn.com/inventor-project-dynamic-simulation-guide-en-211220221740/75/Inventor-project-dynamic-simulation-guide-en-10-2048.jpg)