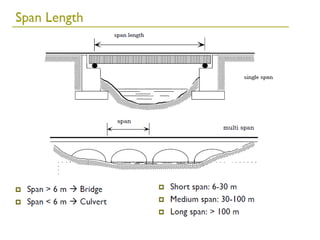

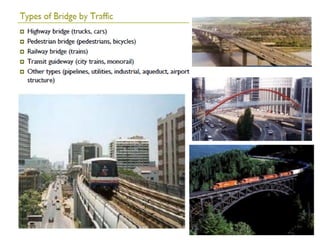

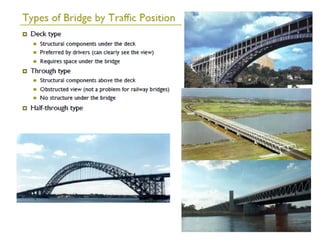

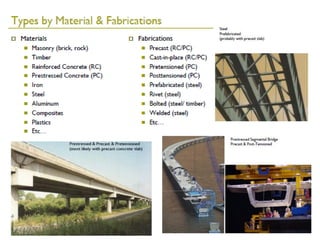

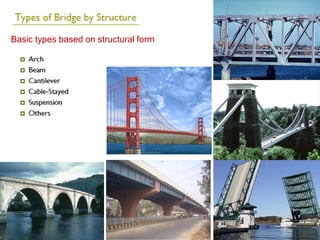

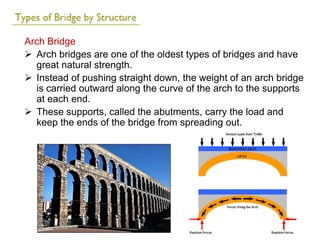

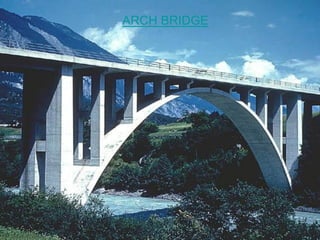

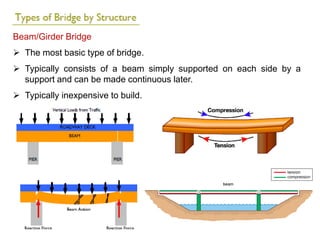

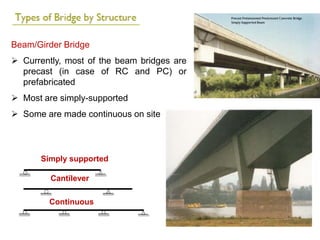

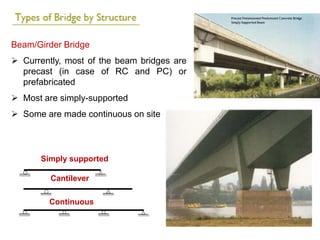

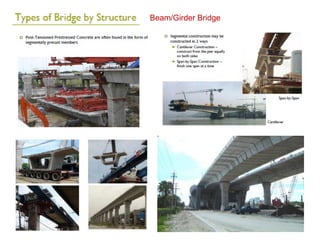

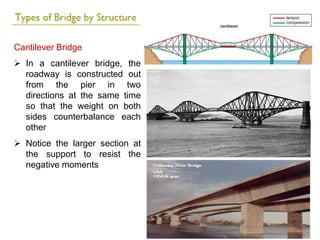

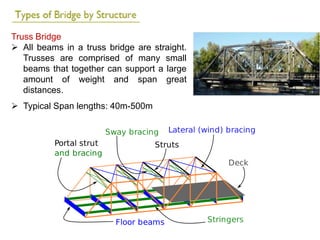

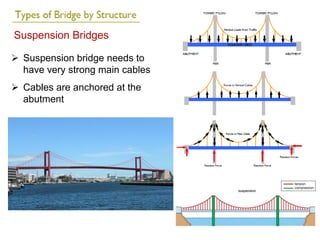

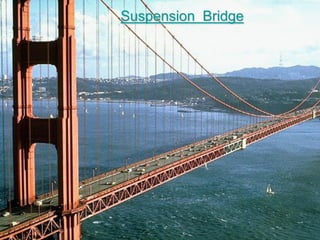

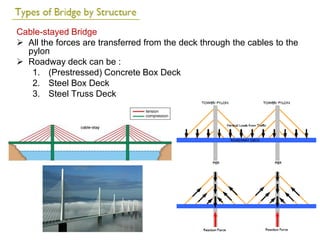

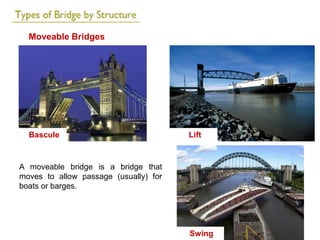

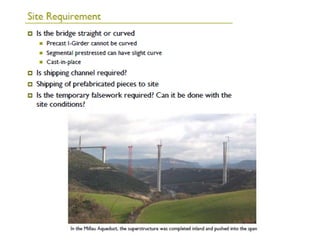

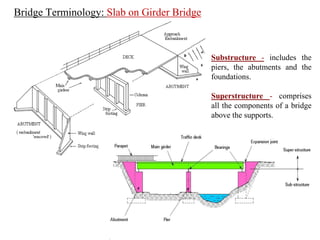

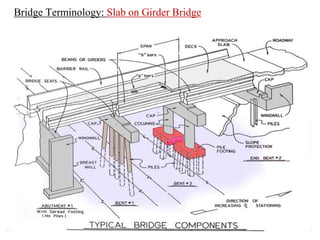

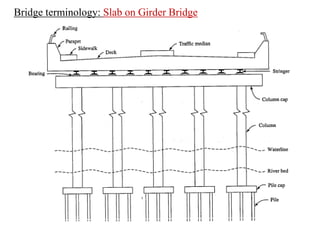

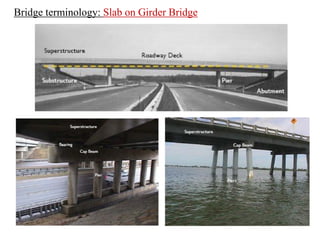

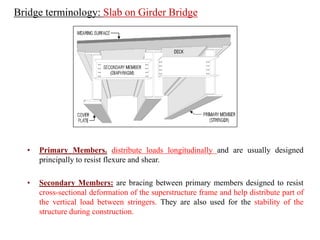

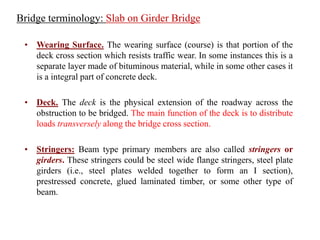

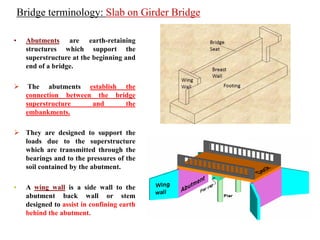

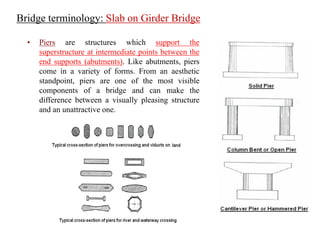

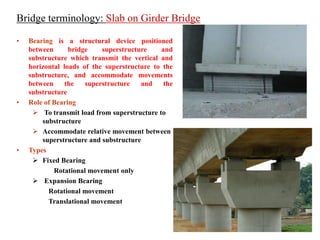

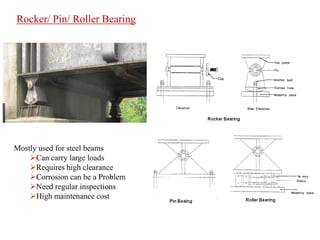

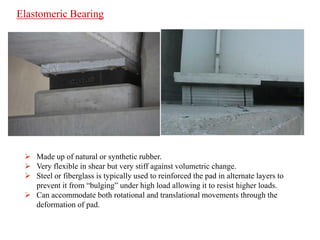

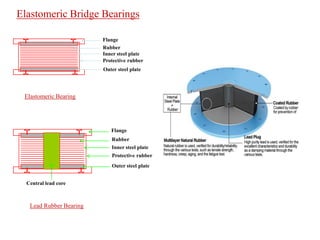

This document provides an introduction to bridge engineering. It defines what a bridge is as a structure that provides passage over an obstacle without blocking the way below. It then discusses basic bridge types including arch bridges, beam/girder bridges, cantilever bridges, truss bridges, suspension bridges, and cable-stayed bridges. The document also covers bridge terminology such as substructure, superstructure, abutments, piers, bearings, and provides descriptions and purposes of these components. Finally, it discusses aesthetics in bridge design and considerations for context, comprehensiveness, cost, and constructability.