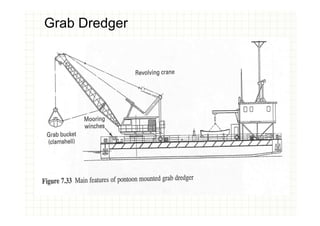

Dredging involves excavating sediments and relocating them using specialized floating equipment called dredgers. There are several types of dredgers that differ in how they excavate and transport sediments. Mechanical dredgers use buckets and grabs to lift sediments, while hydraulic dredgers use pumps to create a slurry of sediments and water. Common dredgers include bucket ladder dredgers, grab dredgers, cutter suction dredgers, and trailing suction hopper dredgers. Dredging is used for capital projects like deepening ports, coastal engineering, and maintenance to maintain navigation depths. While necessary for development, dredging can disturb aquatic ecosystems by changing water chemistry and releasing nutrients and toxicants from sediments.