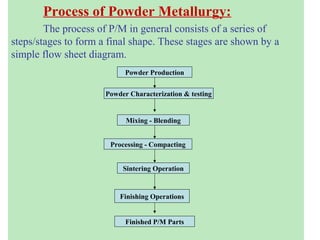

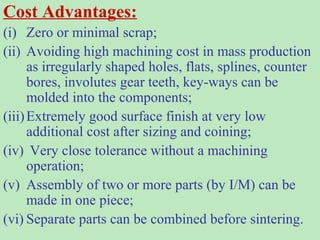

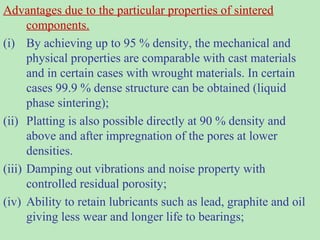

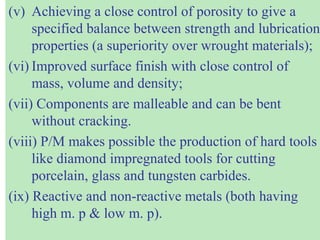

Powder metallurgy is a process that produces metal or ceramic parts from metal or ceramic powders. It allows for compositions and properties not possible with other methods. Parts are made by mixing powders, compacting them into a desired shape, and sintering below the melting point to bond the material. The process offers advantages over other methods like close tolerances, net shape production, and cost savings from reduced machining. However, it is limited by part size and complexity due to compaction requirements.