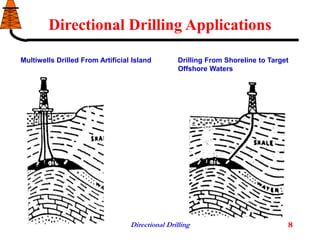

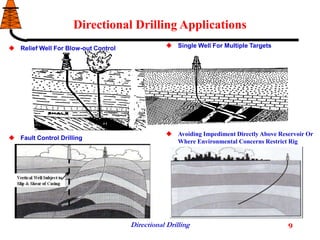

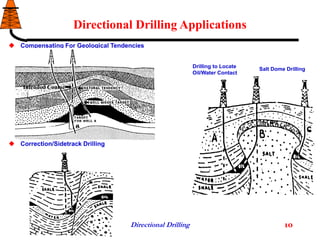

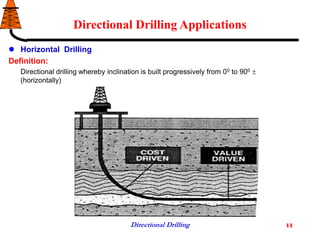

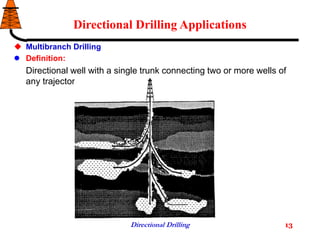

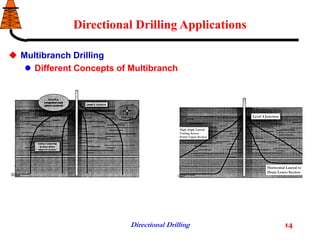

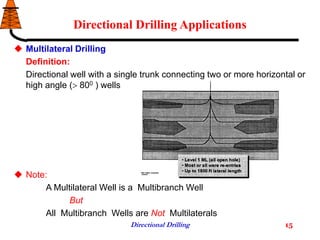

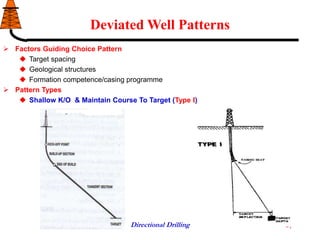

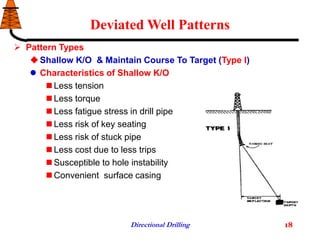

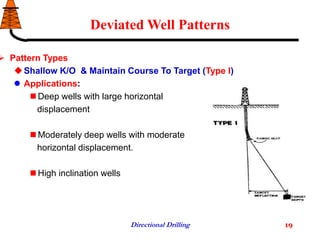

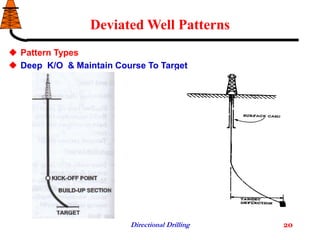

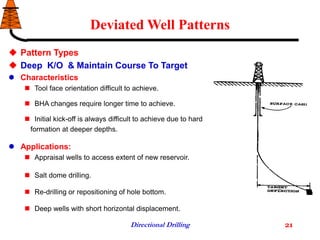

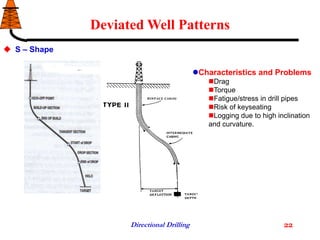

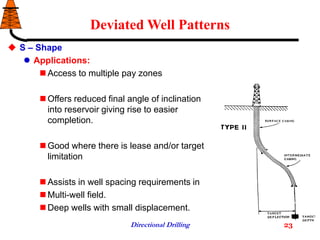

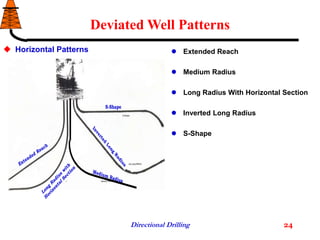

This document provides an introduction to directional drilling and its applications. It defines directional drilling as deviating a well from vertical to a planned subsurface target. Directional drilling is mostly used to avoid structural impediments, for river crossings, high angle wells, and maximizing production from structurally restricted reservoirs like fractured or cavernous reservoirs. Applications include multi-well drilling from artificial islands or shorelines, relief wells, fault control drilling, and horizontal drilling. Deviated well patterns include shallow and deep kick-offs, S-shapes, and horizontal patterns like extended reach and various radius wells.