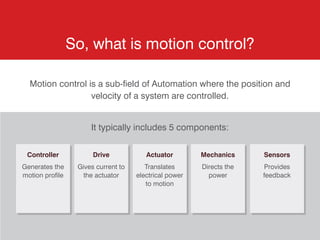

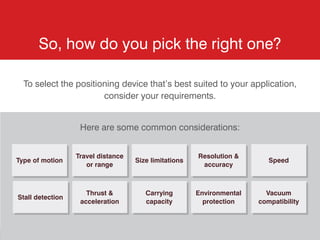

Zaber Technologies, founded in 1997 in Vancouver, specializes in precision motion control technology with a diverse range of products, including linear actuators and rotary stages, designed for high-performance applications in various industries such as photonics, aerospace, and laboratory automation. Their motion control solutions integrate key components like controllers, actuators, and sensors to facilitate precise positioning, catering to specific customer requirements for speed, resolution, and environmental compatibility. Zaber offers user-friendly setup processes with built-in controllers and supports their products with a 30-day satisfaction guarantee and available technical assistance.

![www.zaber.com

Do you need consistent motion?

Repeatability is the deviation in actual position when a device is

repeatedly instructed to move to a target position from the same

direction.

50

45

40

35

30

25

20

15

10

5

0

Measured final position [µm]

Numberoftrials

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8](https://image.slidesharecdn.com/intromotioncontrolslides-140814101943-phpapp02/85/An-Introduction-to-Precision-Motion-Control-20-320.jpg)

![www.zaber.com

Do you need to be accurate?

Accuracy is the measure of how close the actual position will be

compared to the requested position over the entire travel range.

Target Position [µm]

PositionError(µm)

4

3

2

1

0

-1

-2

-3

-4

0 500 1000 1500 2000 2500 3000 3500 4000

T-LSMxxxA Typical Accuracy over 4 mm](https://image.slidesharecdn.com/intromotioncontrolslides-140814101943-phpapp02/85/An-Introduction-to-Precision-Motion-Control-21-320.jpg)