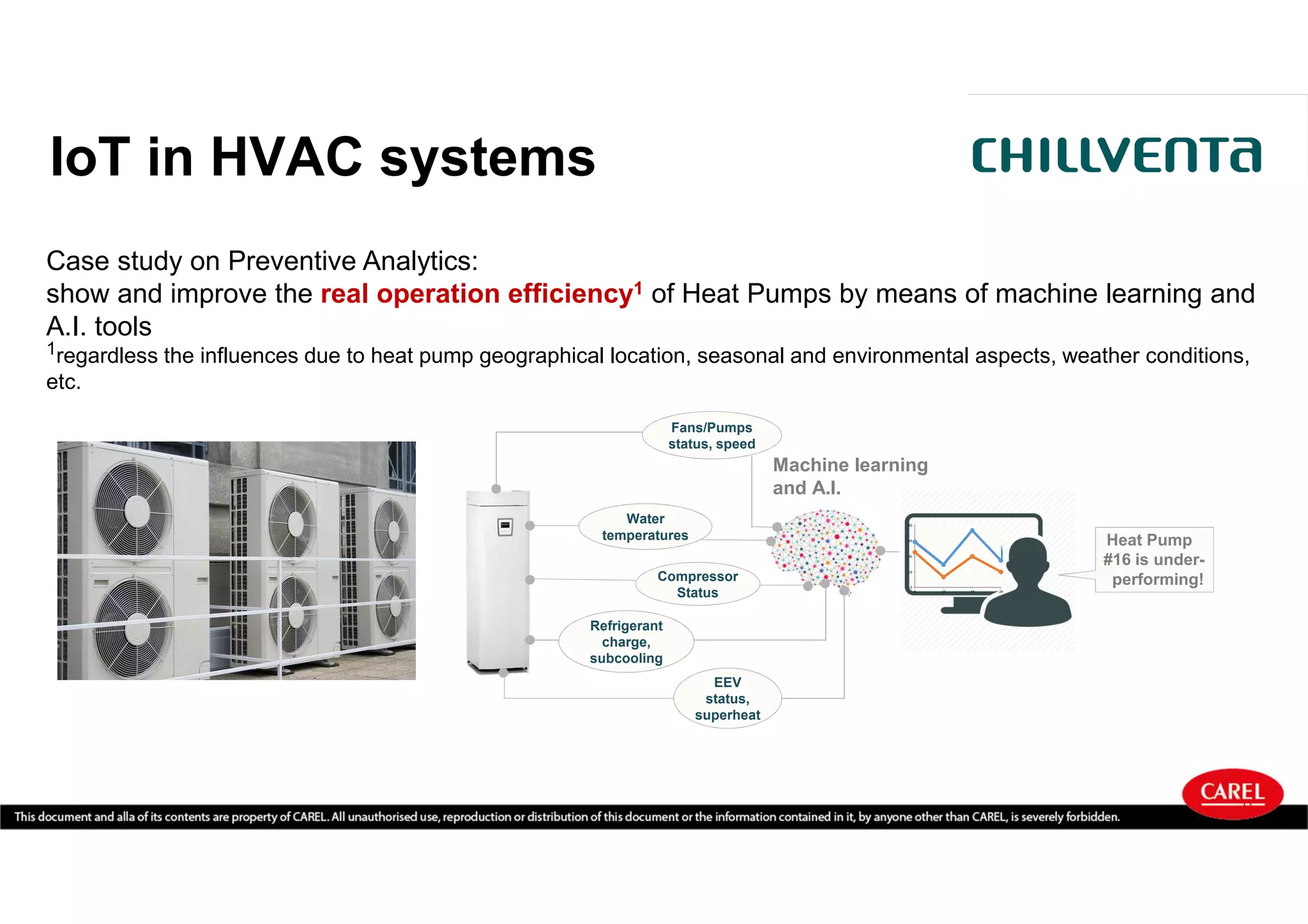

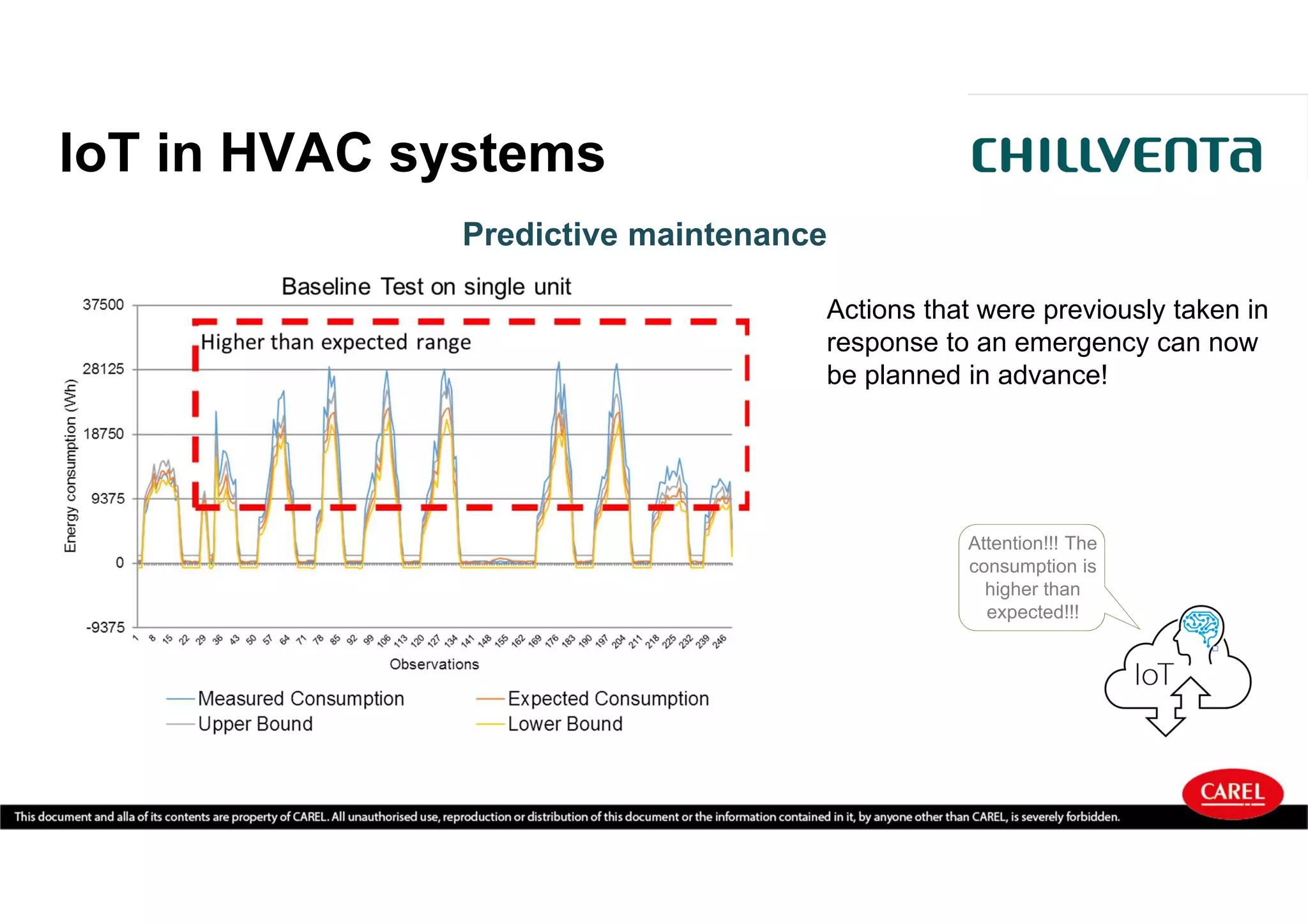

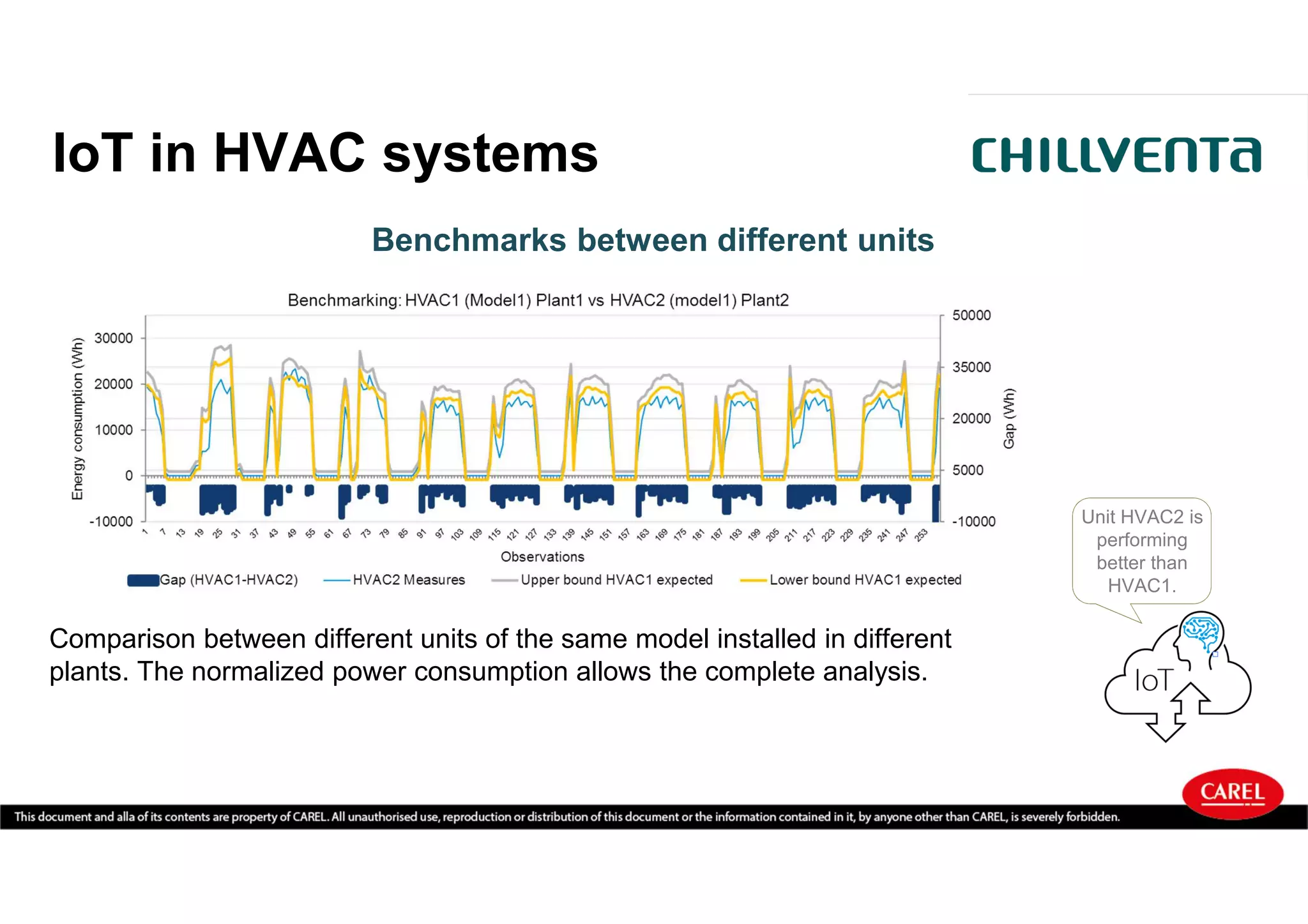

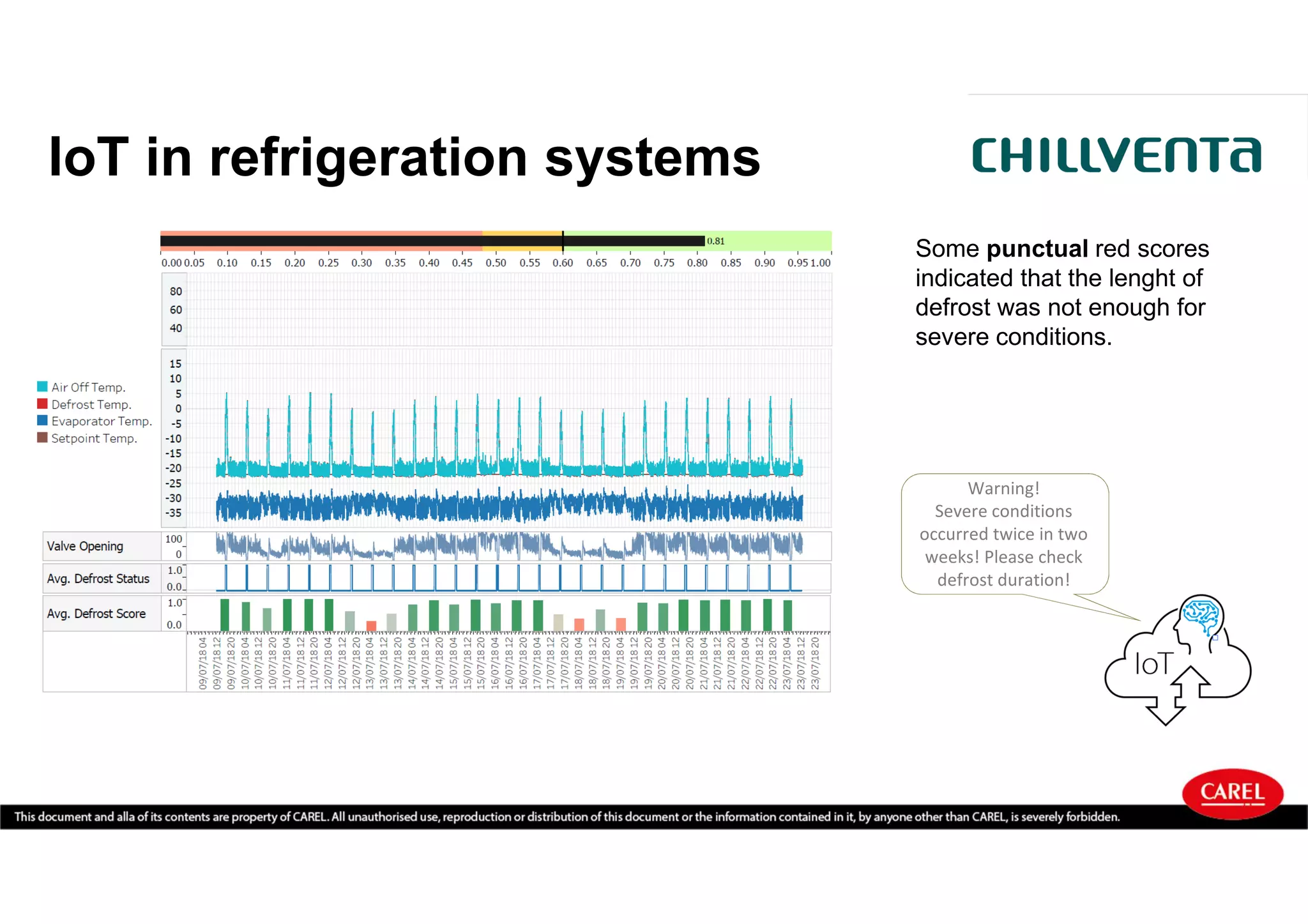

The document discusses the role of the Internet of Things (IoT) in heating, ventilation, air conditioning, and refrigeration (HVAC/R) systems, highlighting its ability to collect and analyze data from connected devices. It explains various analytics types relevant for IoT applications and provides case studies demonstrating the potential for performance optimization, predictive maintenance, and overall energy savings in HVAC/R systems through machine learning. The conclusion emphasizes the benefits of IoT implementation, addressing challenges such as privacy, security, and connectivity.