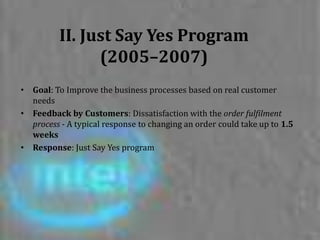

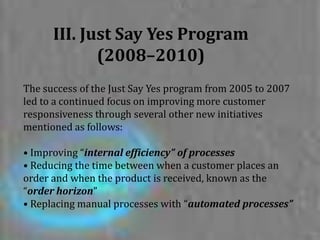

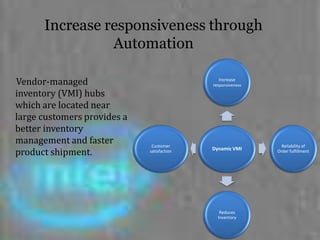

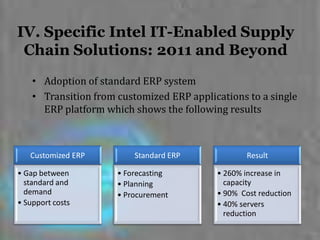

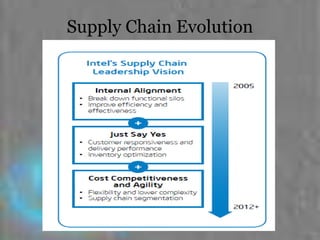

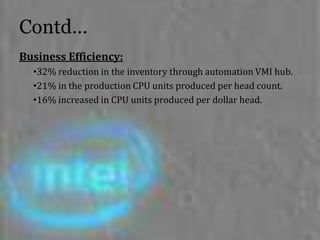

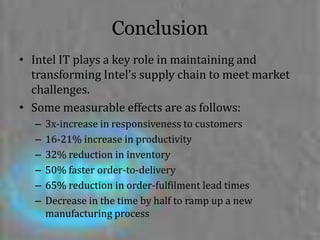

Intel has a global supply chain that manufactures computer processors. It faces challenges from shifting markets and new technologies. Intel IT has helped transform Intel's supply chain through programs like Just Say Yes from 2005-2010. This included improving demand forecasting, reducing order changes, and shortening order timelines. Intel IT consolidated data systems and implemented a standardized ERP system. These changes led to faster response times to customers, higher productivity, reduced inventory levels, and improved ability to launch new manufacturing processes.