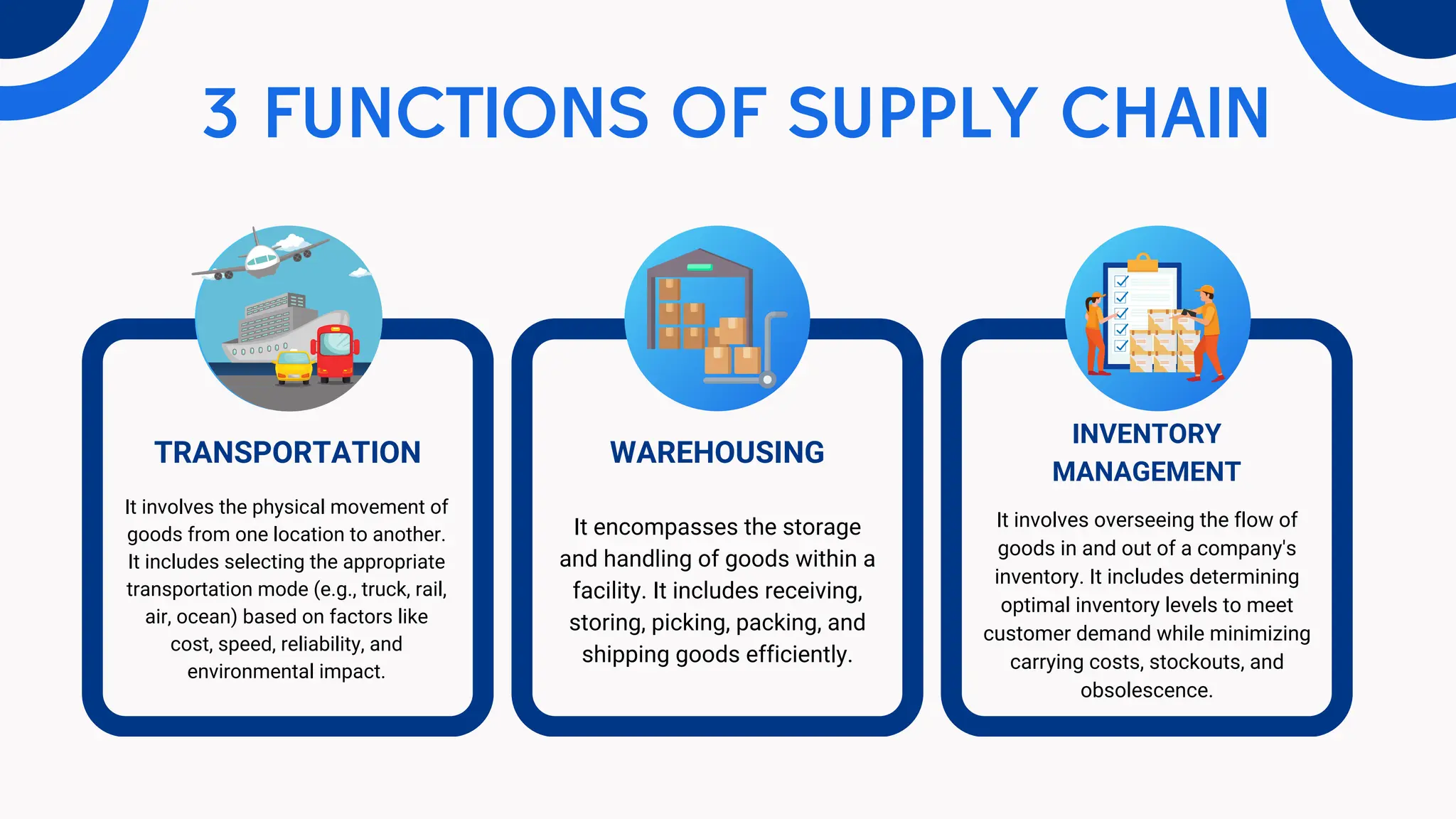

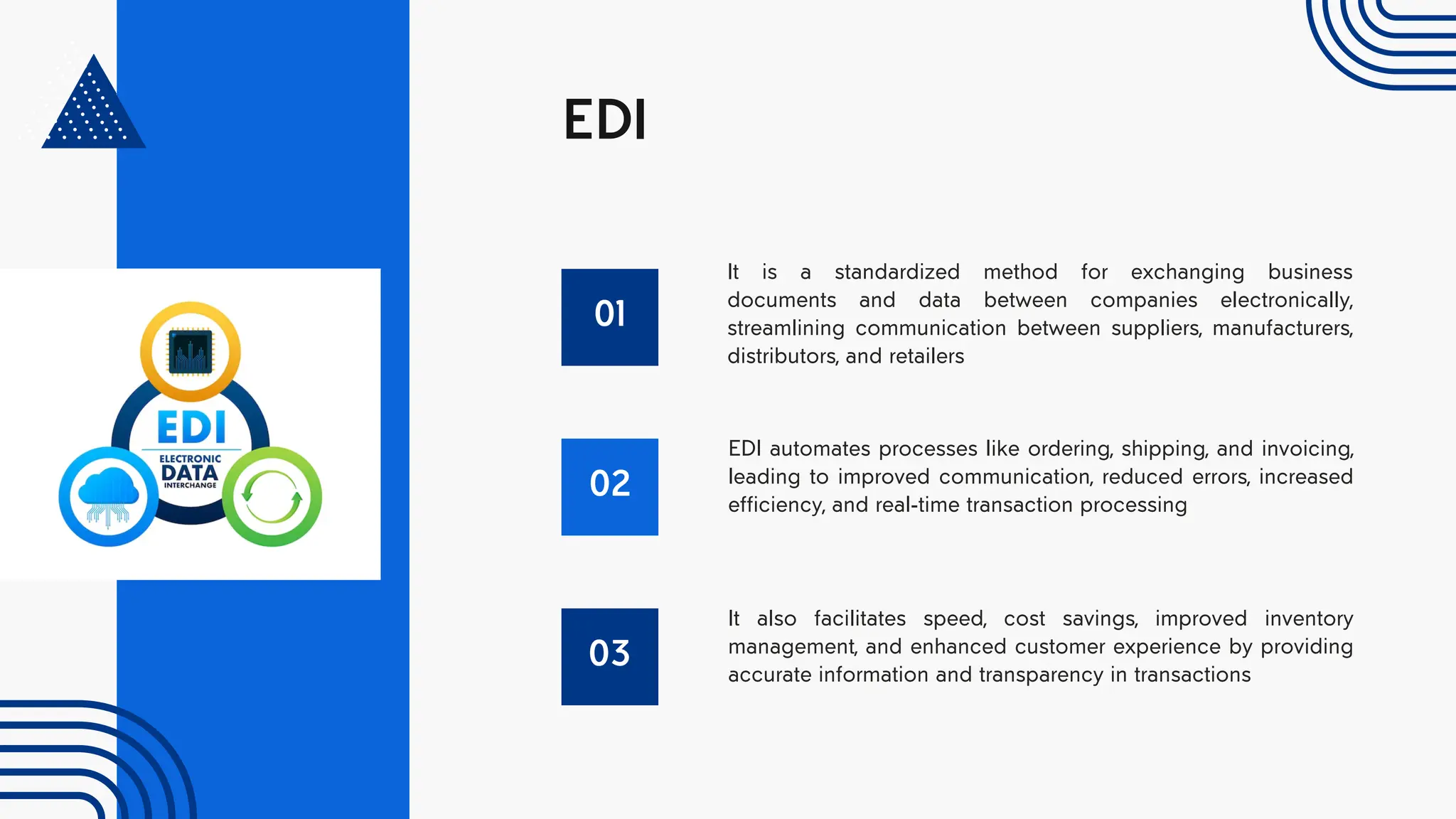

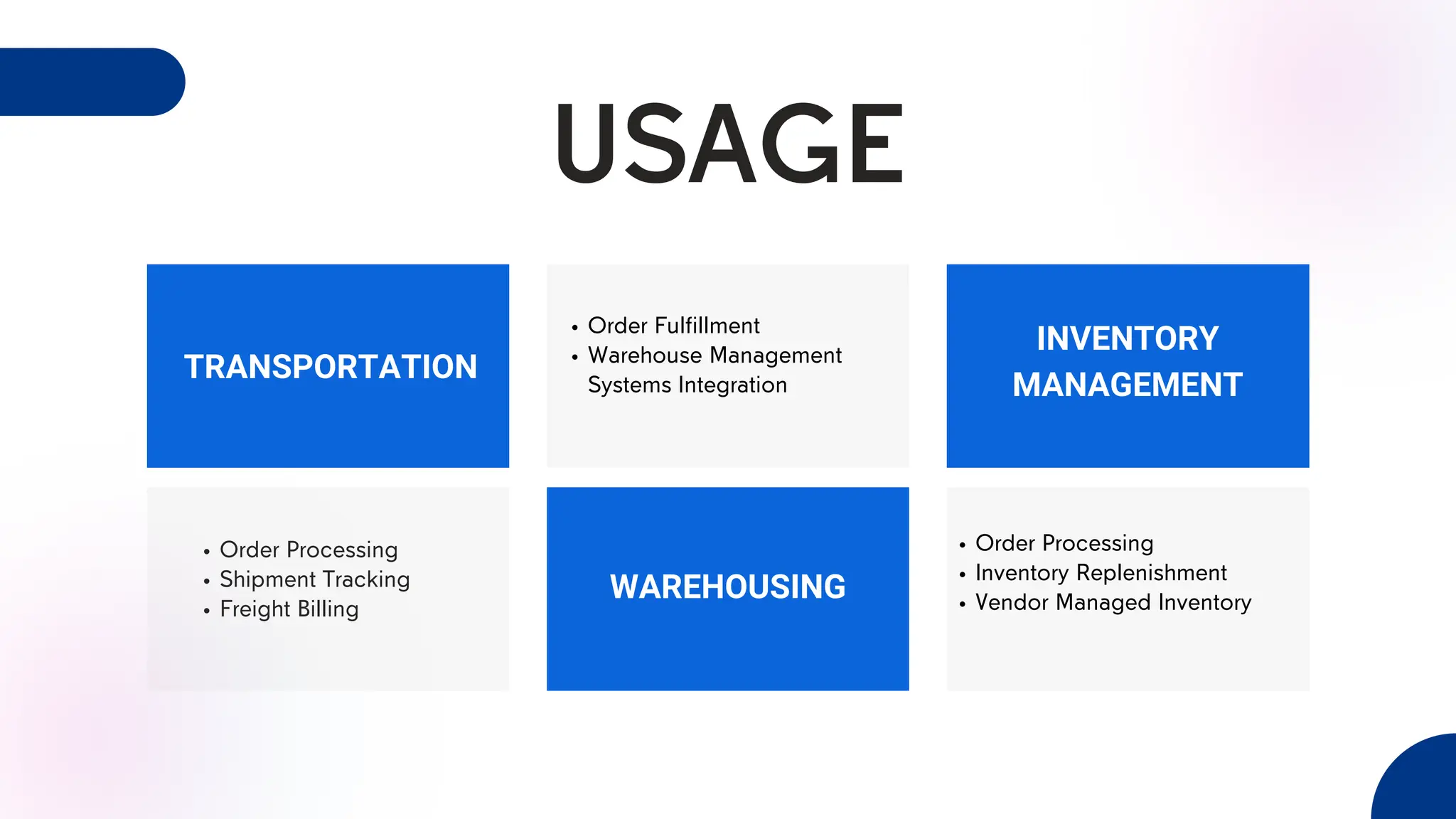

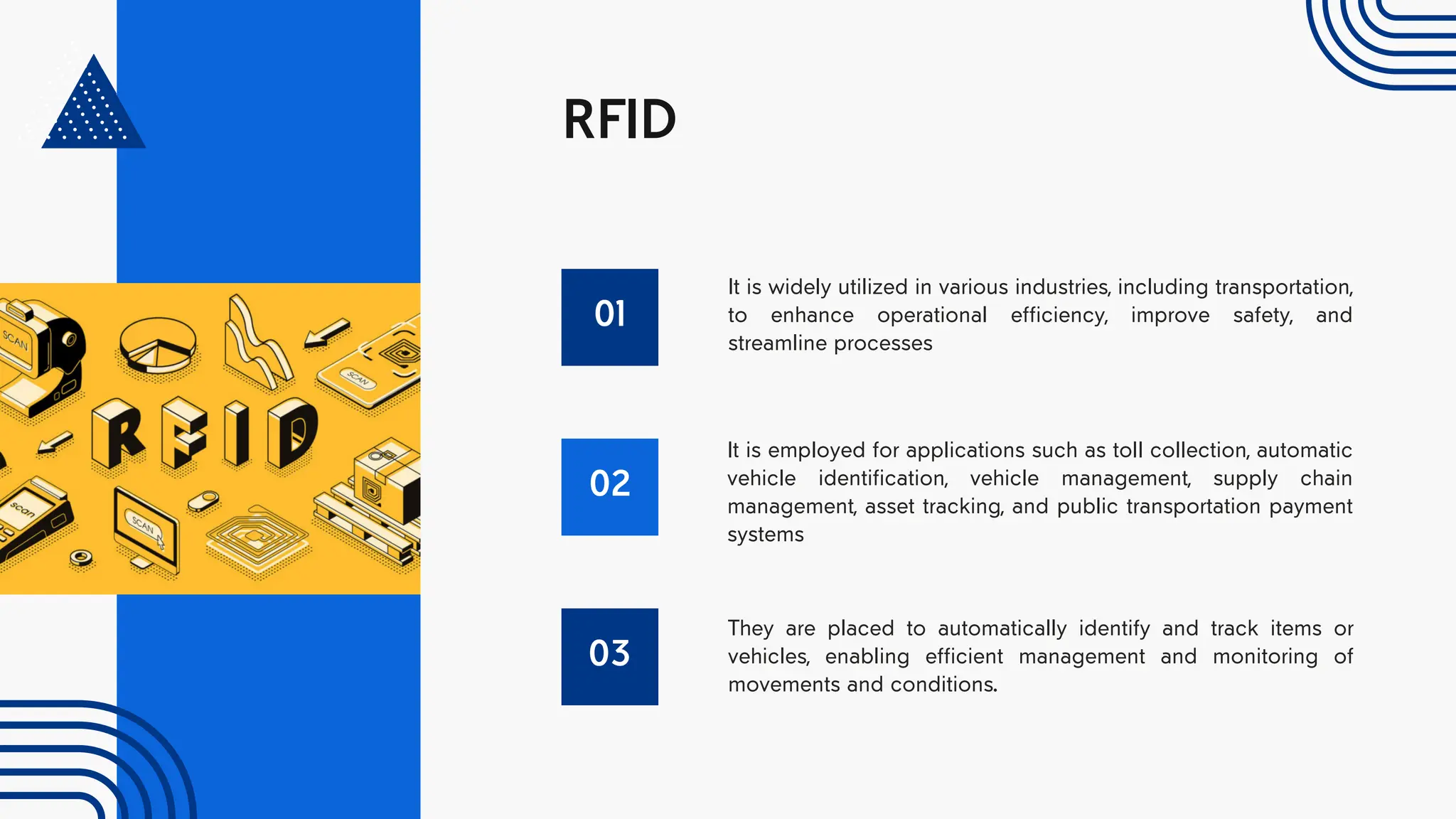

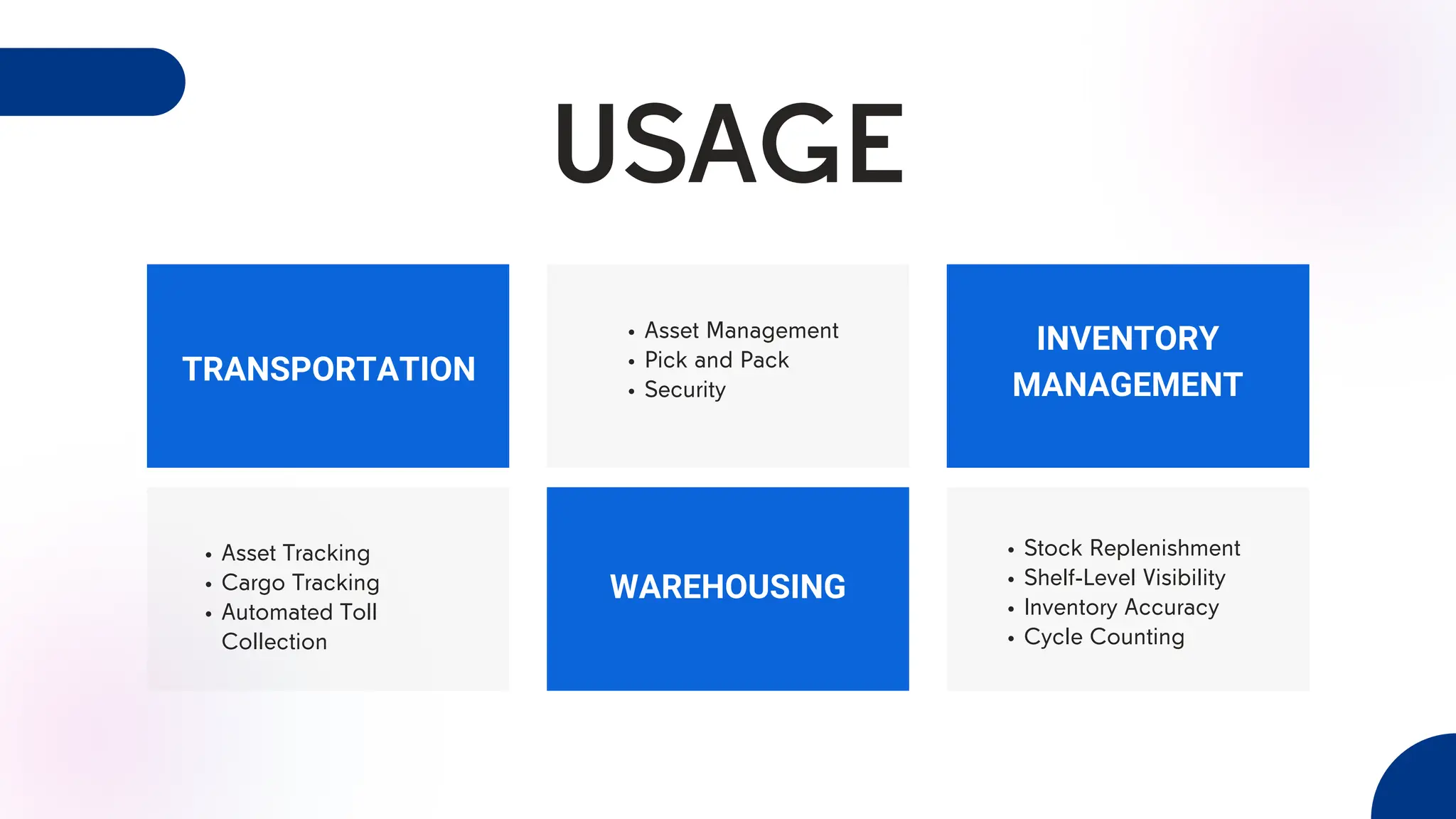

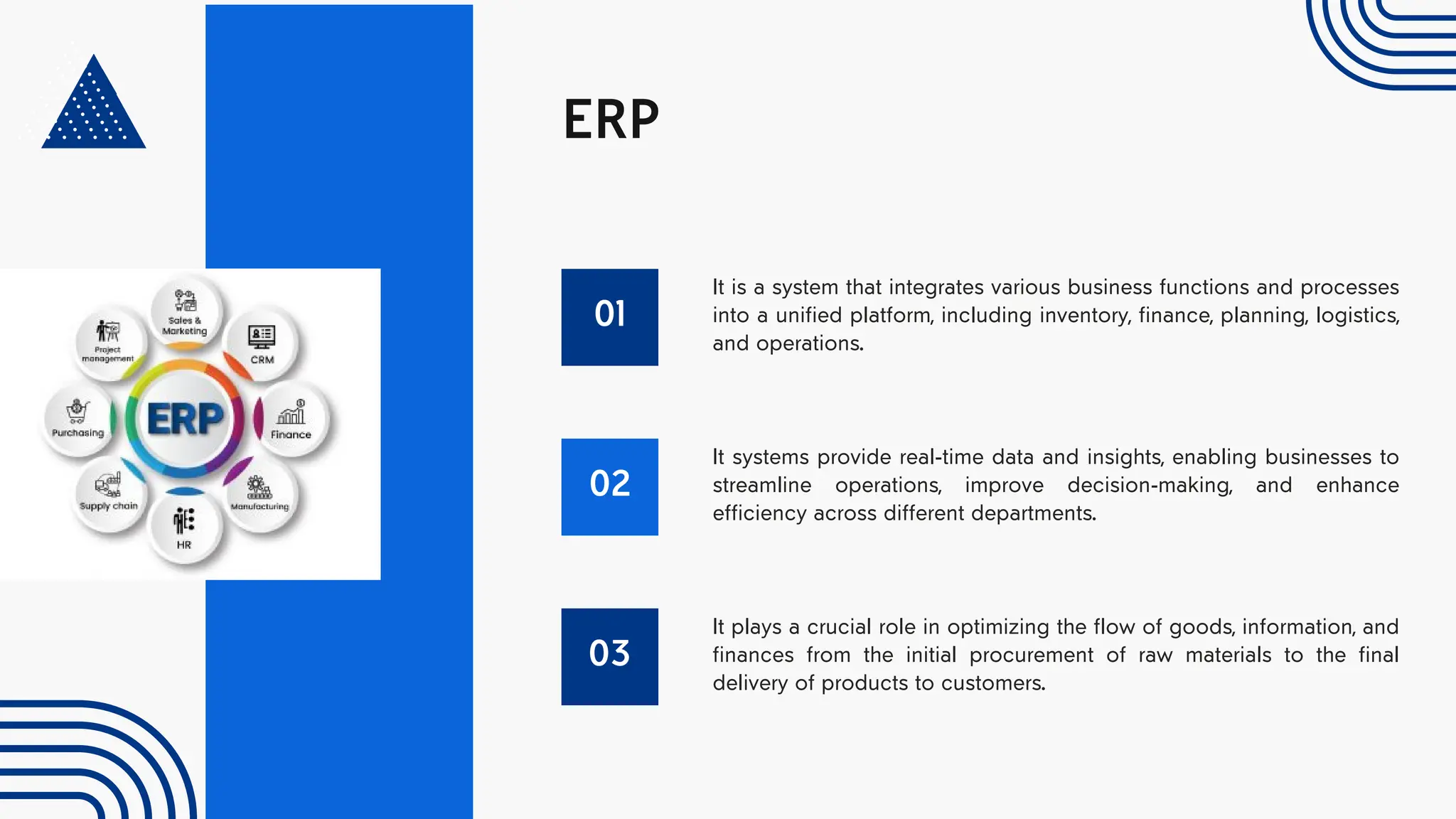

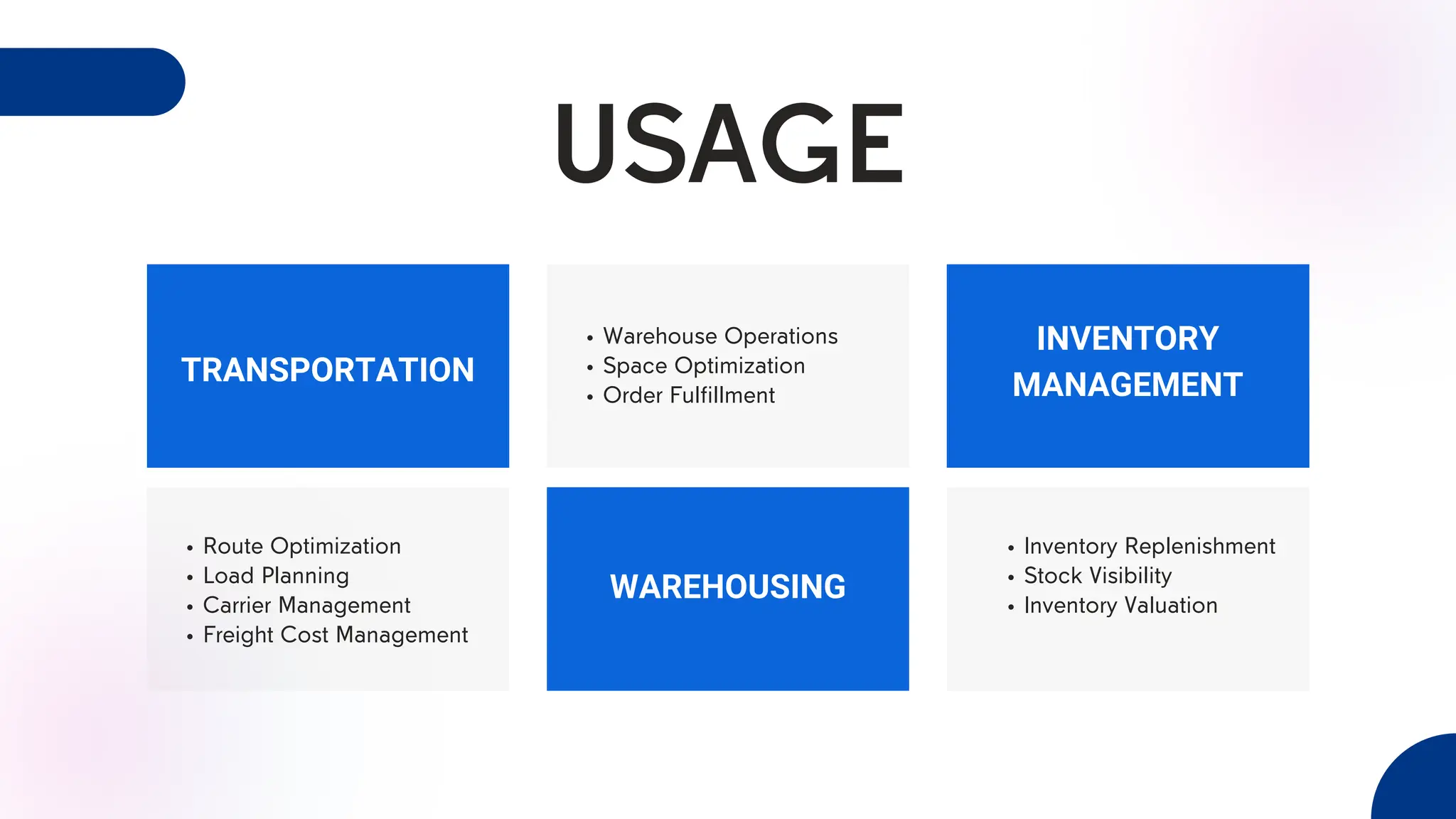

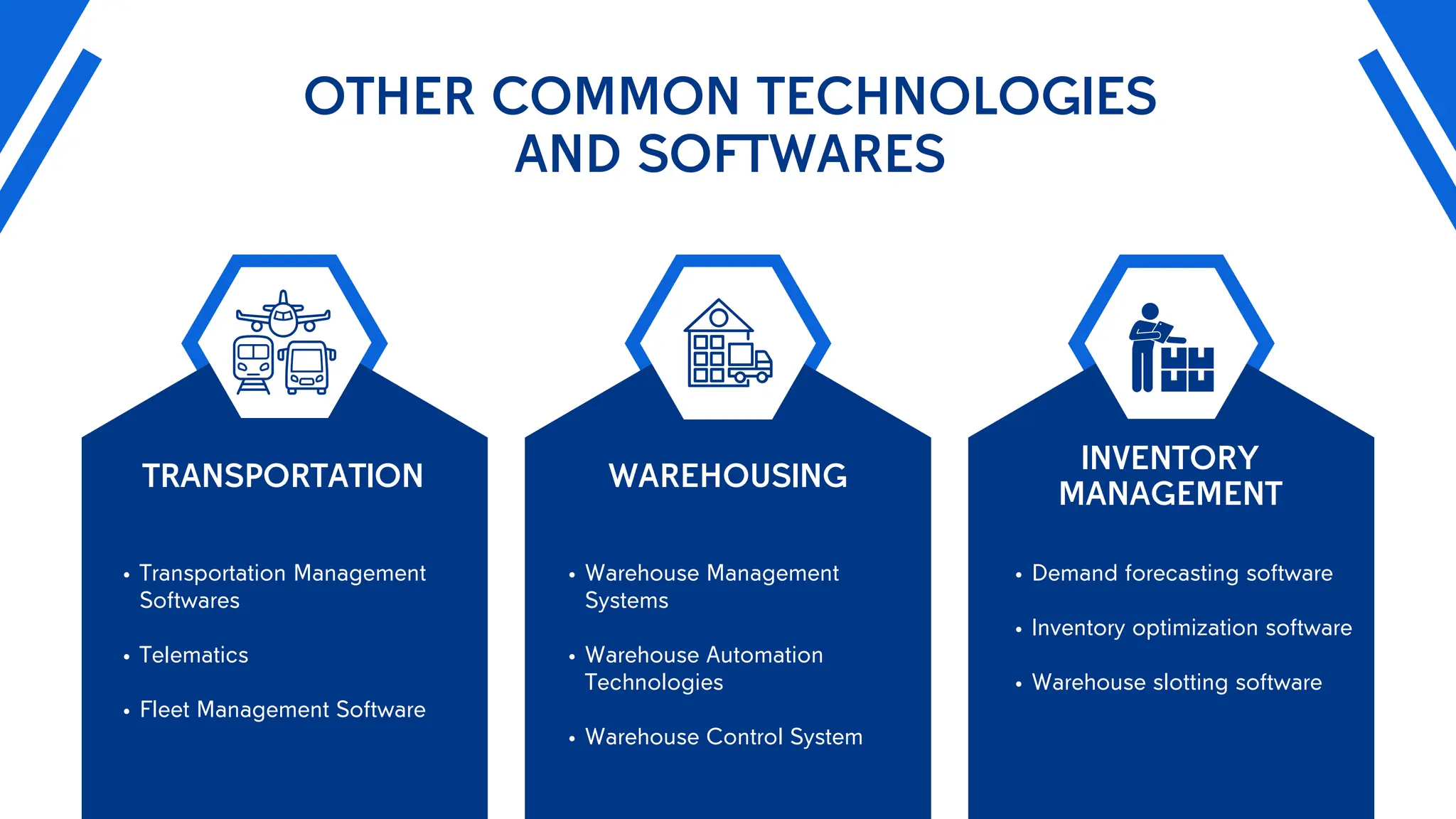

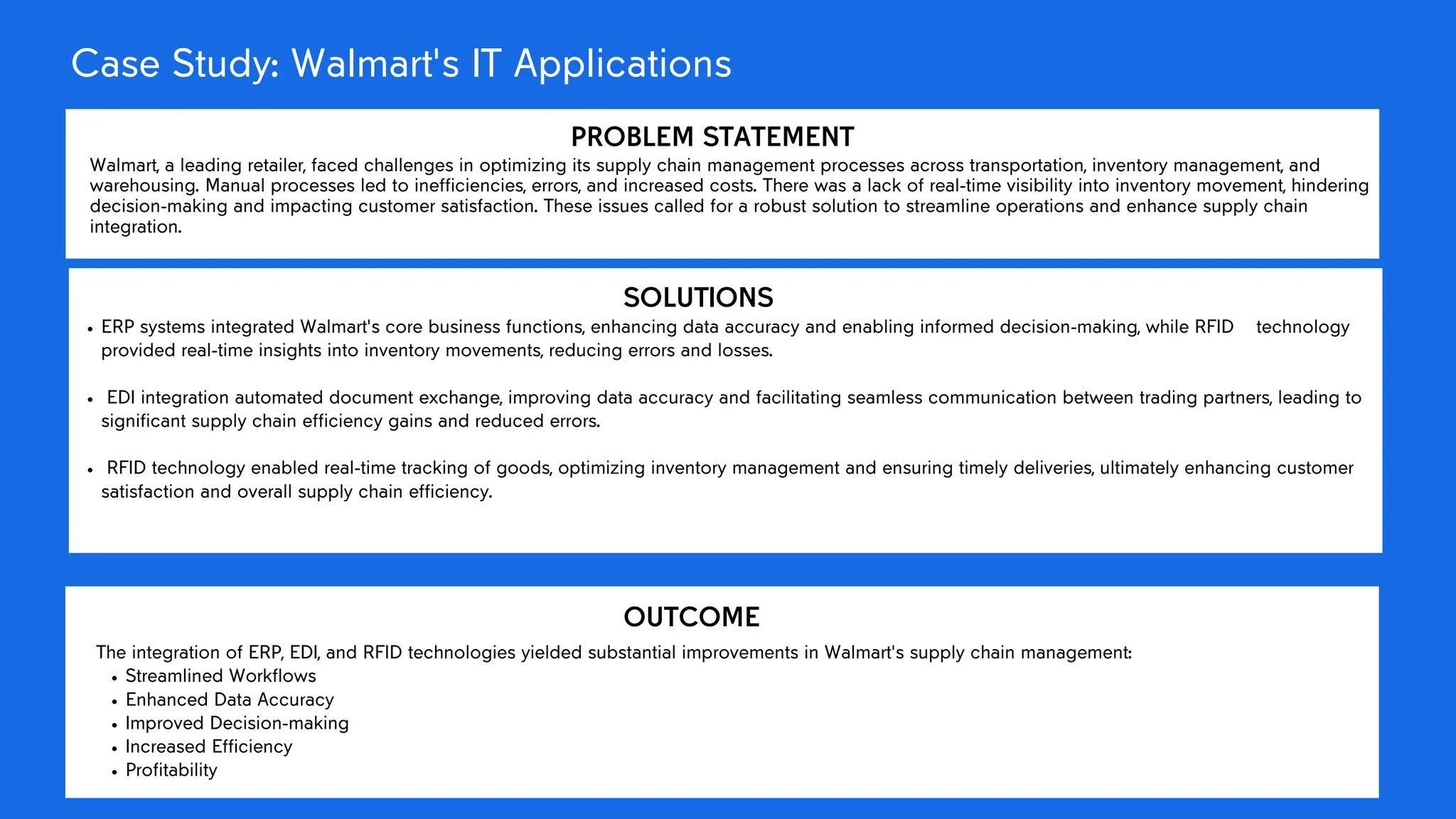

The document discusses the role of information technology in supply chain management. It describes how IT applications like ERP systems, EDI, RFID, and transportation management software help optimize inventory management, transportation, and warehousing functions. A case study on Walmart highlights how integrating ERP, EDI, and RFID technologies streamlined their workflows, improved data accuracy and decision making, increased efficiency, and enhanced profitability.