Industrial training report ( internship shezan)

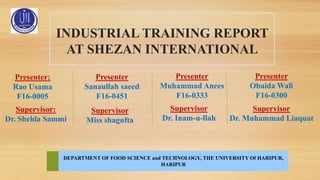

- 1. INDUSTRIAL TRAINING REPORT AT SHEZAN INTERNATIONAL DEPARTMENT OF FOOD SCIENCE and TECHNOLOGY, THE UNIVERSITY Of HARIPUR, HARIPUR Presenter: Rao Usama F16-0005 Supervisor: Dr. Shehla Sammi 1 Presenter Sanaullah saeed F16-0451 Supervisor Miss shagufta Presenter Muhammad Anees F16-0333 Supervisor Dr. Inam-u-llah Presenter Obaida Wali F16-0300 Supervisor Dr. Muhammad Liaquat

- 2. • Introduction • Pulp preparation • Tomato ketchup preparation • Jams and marmalades • Mango juices • Mango squash • Pickle production • chutney • Canning • Quality control • Conclusion 2 Outline

- 3. INTRODUCTION

- 4. History • Shezan international limited is a Pakistani beverage manufacturer based in Hattar industrial estate. It is the largest beverage company in Pakistan. It is the part of shahnawaz group • The company was incorporated on May30, 1964 as a private limited concern and initially conceived as a joint venture with Alliance Industrial Development Corporation of U.S.A for processing citrus and other fruits as well as bottling of juices • In 1971 the Shahnawaz Group purchased all the shares of Alliance Industrial Development Corporation with the permission to Pakistan Government and from a joint venture company it became a fully Pakistani owned company • In 1980-81 a separate unit was installed in Karachi, which now caters for Karachi, Sind and export demand • . A new bottle filling plant was set up in 1983 in the Lahore unit, increasing the capacity five folds. • An independent Tetra Brick plant was commissioned in 1987 making the unit leading manufactures with comprehensive range of production in the fruit processing field in Pakistan

- 5. Mission • To provide the highest quality fruits and vegetables related juices and products to retail and foodservice customers. • To be the recognized industry leader in quality and service, providing more than expected for our customers, employees, and stakeholders.

- 6. Industry Environment • Shezan is the largest processor of fresh fruits and vegetables in the country • The processing is carried out by qualified food technologists in Shezan’s ultra modern plants at Lahore, Karachi and its wholly owned subsidiary. • Pakistan is blessed with a climate ideally suited to the farming of all kinds of fruits, rich in taste and flavor, sweet, mellow and juicy • For centuries Pakistani farmers have been developing newer strains of fruit by grafting one exotic variety with another.

- 7. Achievements • 100% halal products • HACCP certified • received the ISO certifications; 9001-2008 and 22000-2005 • received the prestigious Consumer Choice Award in 2013 • Received the Quality Food Products certificate from the Rawalpindi Chamber Of Commerce. • Honored by the Karachi Stock Exchange when The Top Companies Award was accepted, in 1994.

- 8. Product list • Shezan international produce a number of products which are listed below • Beverages • Squashes and syrups • Jams, jellies and marmalades • Ketchup and sauces • Chinese sauces and vinegar • Pickles • Chutneys • Food essentials

- 11. MANGO PULP PREPARATION Sorting Roller Conveyer Brush Washer Bucket Elevator PulperFinisher Pulp Collection Chemical Mixing (C7H5NaO2, K2S2O5) Pasteurizer (90-950) Cooling (Normal Temperature) Packing & Storage

- 12. PREPARATION OF TOMATO PULP Sorting Washing (dip washing) Thermo Break Chemical Mixing (C7H5NaO2, K2S2O5) Finisher Heat Exchanger (850) Evaporator & Concentrator Storage

- 13. Chapter 3 TOMATO KETCHUP PREPARATION

- 14. Recipe (Approximate) • Tomato Paste 1000 Kg • Sugar 135 Kg • Citric Acid 500-600 Gm • Potasium Sorbate • Color Sunset Yellow + Carmosine • Acetic Acid 2 Kg • Red Chilies • Onion • Salt • Cinnamon • Cumin Procedure • Heating and agitation • Until brix 360–370 • Add seasoning to the pan in blended form • Add color and preservatives at end • Cooking time 20-25 minutes • Homogenizing at 100-120 bar pressure

- 15. Filling Shrink Wrapping And Packaging Quality Standards, Acidity=1.2-1.4% Brix=360

- 16. Chapter 4 Jams And Marmalades

- 17. Jams Ingredients • Fruit pulp • Sugar • Pectin • Color • Flavor • Potassium sorbate • Sodium benzoate • Citric acid Procedure • Heating and agitation • Addition of sugar • At 100-1100C, filter the material to next pan • Addition of pectin solution ( 1:1 sugar and pectin in hot water at 700-1000C) • Add color, flavor, citric acid and preservatives • Brix = 68-69 • pH = 3.0-3.2

- 18. Marmalade Ingredients • Shreds of peels • Sugar syrup • Pectin • Color • Flavor • Sodium benzoate • Citric acid Procedures • Prepare sugar syrup at 100-1100C • Filtration • Addition of shreds of peel ( boiled in water for 4 minute) • Boil mixture of peels and syrup • Addition of pectin mixture • Color, flavor, citric acid and preservatives • Brix = 68-690 • Ph = 3.0-3.2

- 20. Juice preparation include following procedure Ingredients • Mango pulp • Sugar syrup • Water • Color • Flavor • Citric acid • Sodium benzoate(preservative) • Guar gum(stabilizer) Quality standards • Brix = 13-13.50 • Acidity = 0.15-0.17% • pH = 3.4±0.1 • Volume = 240-245 ml

- 21. Procedure Pulp Testing To Blending Tank Syrup Preparation Juice Blending Homogenization Juice Storage Tank Bottling

- 22. Juice Bottling Loading Conveyer Sorting Of Bottles Uncaser Machine Bottle Conveyer Washer Machine Water Station Washed Bottle Inspection Filler Feed Conveyer Pasteurizer Filler Filled Bottle Inspection Ink Jet Coder Outer Cleaning Of Bottles Table Conveyer Stacking & Storage

- 24. Ingredients • Mango Pulp • Sugar Syrup • CMC (Carboxymethyl cellulose) • Color • Flavor • Citric Acid • Potassium Meta-bisulphite (Preservative) Process • Heating of pulp at 500C • Filtration of CMC and pulp • Squash blending; sugar syrup, water, citric acid, color and flavor • Standard brix; if less sugar is added and water if high • Storage tank (cooling) • Filling • Capping, labelling and packging

- 25. Quality standards • Acidity = 1.5 ± 0.05 • Brix = 500 ± 0.050 • Free SO2 = 400 ± 50 ppm • Volume = 735 - 740 ml

- 27. Procurement And Preservation Of Fruits And Vegetables For Pickle Production Preservation Of Mangoes • Receipt Of Raw Material • Sorting • Cutting • First Salting (10% salt by weight of mangoes) • Over Night Stay • Drainage • Second Salting • Brining (15-20% brine solution) • Storage Green chilli preservation • Receipt Of Raw Material • Sorting • Salting • Overnight Stay • Brining

- 28. Lime Preservation • Receipt of raw material • Sorting • Brining Berigold Preservation • Sorting • Salting • Overnight Stay • Brining Carrot Preservation • Receipt of raw material • Peeling • Cutting into slices • Salting • Overnight stay • Brining

- 29. Ingredients • Prepared raw material (mangoes, lime, green chillies, berigold, slices of carrot) • Salt (99% pure) • Mustard oil • Spices (red chillies, fenugreek seed, turmeric, cumin seed, dill seed, garlic) • Acids (citric and glacial acetic acid) Procedure • Washing of raw material • Sorting • Raw material preparation; cap removing of berigold and cutting of lime into half) • Frying in oil • Addition of spices • Overnight stay in pan • Oil separation • Filling

- 30. Jar Filling Oil Addition Material In Jar Outer Cleaning Oil Level Maintaining Weighing Neck Cleaning Bottom Cleaning Capping Hot Water Washing Drying Labelling Packaging And Stacking Shrink Wrapping

- 32. Ingredients • 1. Plum Pulp • 2. Dry Plum • 3. Sugar • 4. Spices:( Red chilli, Garlic Paste, cumin and clove, salt) • 5. Sodium benzoate Procedure • Mixing in cooking pan(pulp, spices, sugar) • Heating and agitation till brix reaches 76 • Dries plumps are added (washed) after brix reaches 76 • Two to three boils till brix 72 • Ready for filling and transportation

- 35. Unit Operation In Canning Preparation Of Raw Material Filling Syruping, Brining Oiling Lidding, Clinching Exhausting Sealing Heat Processing Cooling Labelling Packaging

- 36. QUALITY CONTROL

- 37. QUALITY ASSURANCE • Research and Development is one of the fundamentals of any company. Shezan is one of those companies that give extra importance to this field. • Shezan has a state-of-the-art microbiology labs, where food products are examined and tested and the best quality ingredients are separated • The physic-chemical analysis of the food products is carried out by the trained lab attendees to ensure that every food product is in commensurate with its claimed quality.

- 38. General • Acidity • Brix • pH • TSS Water Testing • Hardness • Phosphate • pH • Sulphide • Nacl • Chlorine • Iron • TDs • TSs • Arsenic Checking Of Pulp • Cloud Stability • (SO2) checking • Smell • Taste • Color • Fermentation

- 39. Water Testing

- 40. Hardness And Its Types The hardness of water is due to the presence of soluble bicarbonates, chlorides, and sulfates of calcium and magnesium. Water which does not give lather with soap is hard water. Types of Hardness i. Temporary Hardness ii. Permanent Hardness

- 41. Procedure: Take 100ml water in a beaker. Add 2ml Ammonia Buffer into the beaker. Add 1-2 drops of Eriochrome Black T. Place the beaker into the magnetic stirrer. Titrate with ethylenediaminetetraacetic acid (EDTA) 0.02N. Note the reading. End point is sky blue. Formula: Edta used * 20 100

- 42. pH pH of water is a measure of amount of hydrogen ions that is present in the water. It determines if the water is alkaline or acidic in nature. pH stands for potential of hydrogen. As per the World health organization(WHO) value of pH for the water is 6.5 to 8.5. pH can be calculated mathematically as pH = -log[H]

- 43. Determination of Sulphite(so3) Measure 50 ml of the sample in a measuring cylinder. Transfer 50 ml of sample into a conical flask. Add 1 ml of Hcl 6N into the sample. Add 2 ml of starch indicator into the sample. Shake to mix solution. Titrate with potassium Iodine-Iodate until a faint blue is obtained. Note down the volume used. Sulphite= 20*ml of potassium iodide-iodate used in titration

- 44. Determination of Chlorine Add 5 drops of chlorine reagent 1 in a glass vessel. Add 2 drops of chlorine reagent 3 and 3 drops of chlorine 2 in the same vessel. Now add water in the vessel and raise up to 5 ml. Wait for 2 minutes. Compare the colour of solution with the given comparator sheets. Note the reading.

- 45. Determination of iron Take 10 ml of water sample. Add iron reagent. Mix the solution. Compare the solution with the given comparator sheets. Note the reading.

- 46. Determination of Arsenic Take 60 ml of water sample in a bottle. Add 1-2 drops of arsenic reagent 1(liquid form). Add arsenic reagent 2(powder form) by green spoon. Add arsenic reagent 3(powder form) by red spoon. Mix the solution gently. Then take one test strip insert into a screw cap in the order that white dots of screw cap and blue line of stripe is facing towards us. Immediately close cap tightly in reaction bottle and wait for 20 minutes. After 20 minutes compare color of reaction zone to color chart.

- 47. TDS A TDS meter is a small hand-held device used to indicate the Total Dissolved Solids in a solution, usually water. Since dissolved ionized solids, such as salts and minerals, increase the conductivity of a solution, a TDS meter measures the conductivity of the solution and estimates the TDS from that reading.

- 48. TSS Total suspended solids (TSS) is the dry-weight of suspended particles, that are not dissolved, in a sample of water that can be trapped by a filter that is analyzed using a filtration apparatus. It is a water quality parameter used to assess the quality of a specimen of any type of water or water body, ocean water for example, or wastewater after treatment in a wastewater treatment plant.

- 49. Determination Of Nitric Strength Take 40 ml water in a beaker. Add 2 ml nitric sample in to the beaker. Add 2-3 drops of phenolphthalein indicator. Place the beaker on the magnetic stirrer. Turn on the magnetic stirrer. Titrate the solution with sodium hydroxide. End point pinkish colour. Note the reading.

- 50. Determination Of Caustic Strength Take 40 ml water in a beaker. Add 10 ml sample of caustic in to the beaker. Add 2-3 drops of phenolphthalein indicator. Turn on the magnetic stirrer. Titrate the solution with H2SO4. End point colourless. Note the reading.

- 51. Juice And Pulp Testing

- 52. Determination of Acidity of juice Take 40 ml water in a beaker. Take 20 ml juice mixed in the beaker. Add 2-3 drops of phenolphthalein indicator. Place on the magnetic stirrer and turn on the stirrer. Titrate the solution with sodium hydroxide(NAOH). End point pinkish colour. Formula = Naoh USED * 2 sample

- 53. Determination of Acidity of pulp Take 60 ml water in a beaker. Add 5 ml pulp in the beaker. Add 2-3 drops of phenolphthalein indicator. Place the beaker on the magnetic stirrer and turn on the stirrer. Titrate the solution with Naoh. End point raddish pinkish colour. Formula = Naoh used * 0.4

- 54. Determination of S02 in pulp Take 60 ml water in a beaker. Take 10 ml pulp sample and mixed in the beaker. Add 1.5 ml H2SO4. Add 1.5 ml starch 1%. Add 1g sodium carbonate Place the beaker on the stirrer and turn on the stirrer. Titrate the solution with iodIne 0.02N ppm. Formula= iodine used* 64

- 55. Cloud Stability Test For Pulp Take 100 ml water in a conical flask. Add 10 ml pulp sample in it. Place the sample in microwave oven for 1.5 min at 100C . Place the sample at room temperature for 4-5 hours. Observe the cloud appear on the top of the table.