This document discusses texture analysis and the components and functions of a texture analyzer. It provides the following key points:

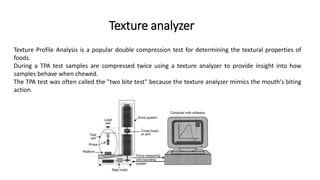

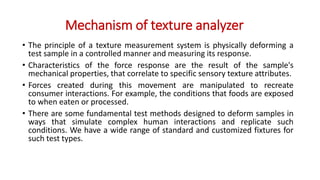

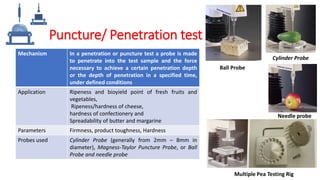

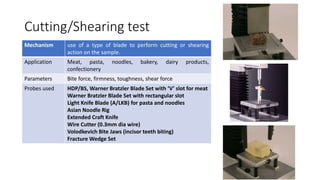

1. A texture analyzer uses controlled deformation of food samples and force measurements to determine textural properties that correlate to sensory attributes. It can perform tests like penetration, compression, cutting, and extrusion that mimic human interactions with food.

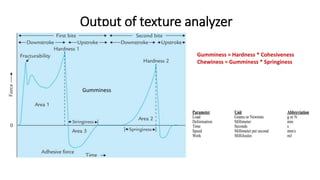

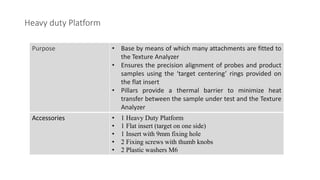

2. Texture analyzer outputs include hardness, cohesiveness, gumminess, springiness and chewiness. It has components like load cells, probes, and platforms to hold samples.

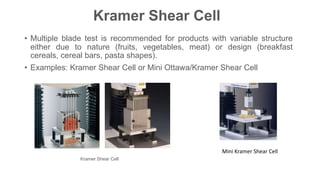

3. Accessories allow it to control temperature, humidity and automate testing. A variety of probes and fixtures exist for different food types and test methods simulating effects of