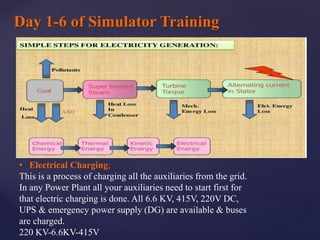

The document is an industrial training presentation by Sashikant Tiwari that acknowledges key figures from UPES and outlines his experience at Rosa Power Supply Company Limited, a coal-based power generation plant in Uttar Pradesh. It details the training program, which included simulator and maintenance training, and provides an overview of the power plant's operations and Reliance Power's involvement in the energy sector. The training enhanced Tiwari's engineering skills and understanding of the industry while also fostering problem-solving and critical thinking abilities.