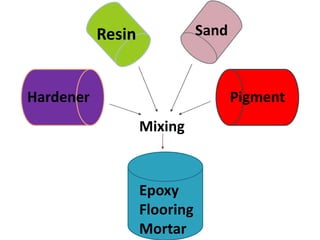

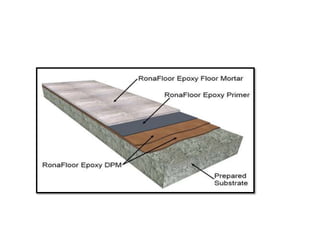

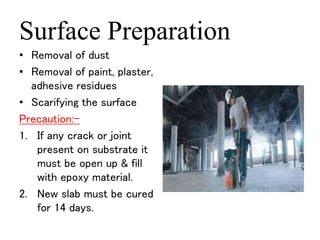

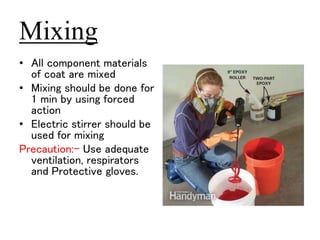

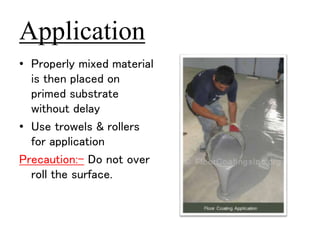

This document discusses epoxy flooring, including its types, application procedure, advantages, and disadvantages. It provides details on surface preparation, priming, mixing, application, and clean up of epoxy flooring. The application procedure involves preparing the surface, priming it, mixing the epoxy components, applying the mixture, and cleaning up. Epoxy flooring offers benefits such as being jointless, hygienic, durable, chemical resistant, and easy to clean, making it suitable for industrial uses. However, it also has high initial costs and requires skilled labor.