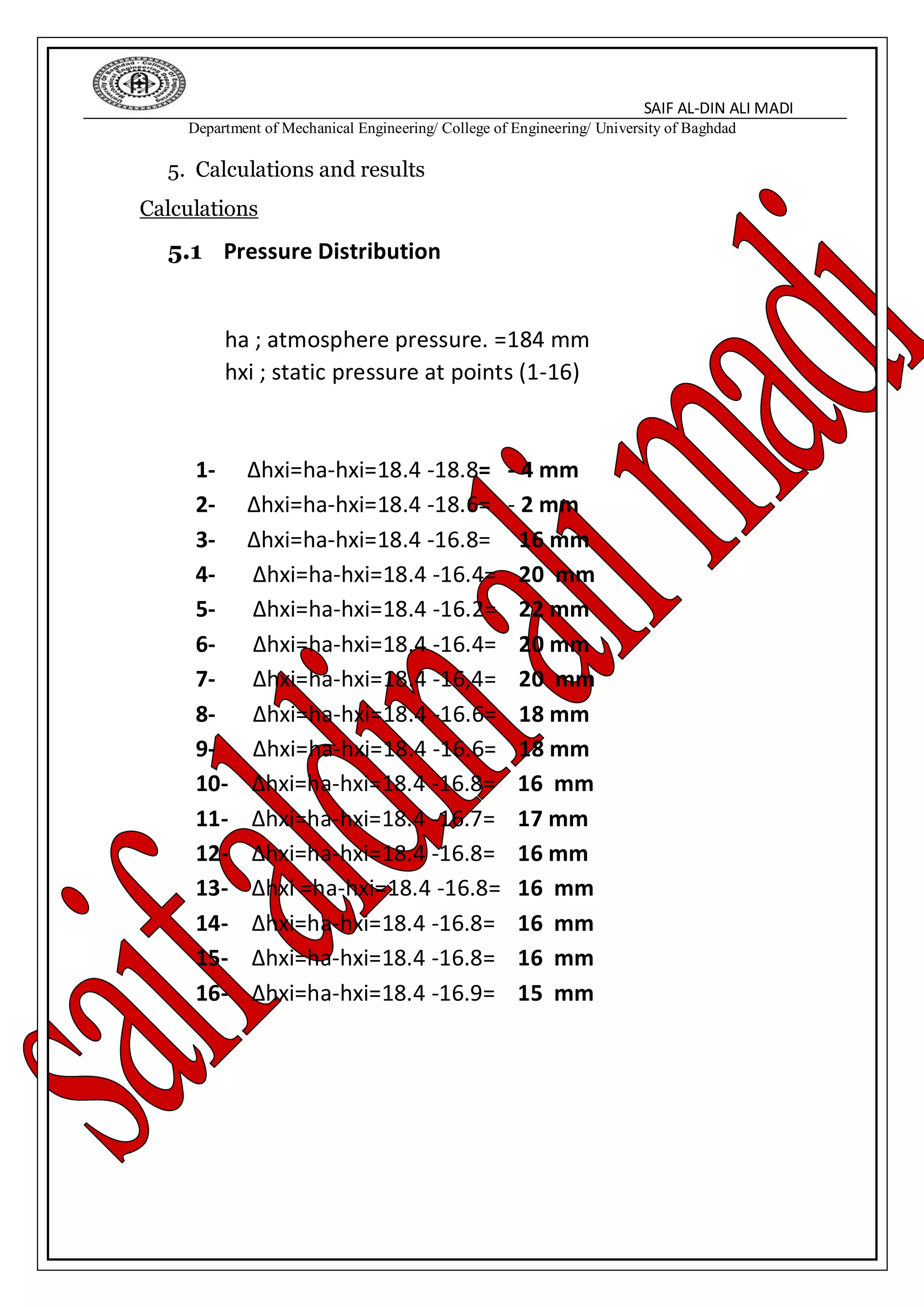

This document discusses fluid mechanics concepts and fluid flow measurement techniques. It begins with defining different types of fluid flows such as steady/unsteady, uniform/non-uniform, and laminar/turbulent flows. It then describes measuring techniques for pressure, including static, dynamic, and stagnation pressures. Common pressure measurement instruments like the U-tube manometer and pressure transducers are also introduced. The document concludes with discussing the boundary layer and formulas for calculating volume flow rate by measuring velocity and duct area.

![SAIF AL-DIN ALI MADI

Department of Mechanical Engineering/ College of Engineering/ University of Baghdad

[Fluid Laboratory II]

University of Baghdad](https://image.slidesharecdn.com/inducedflow-181109205459/75/Induced-flow-Fluid-Laboratory-U-O-B-1-2048.jpg)

![SAIF AL-DIN ALI MADI

Department of Mechanical Engineering/ College of Engineering/ University of Baghdad

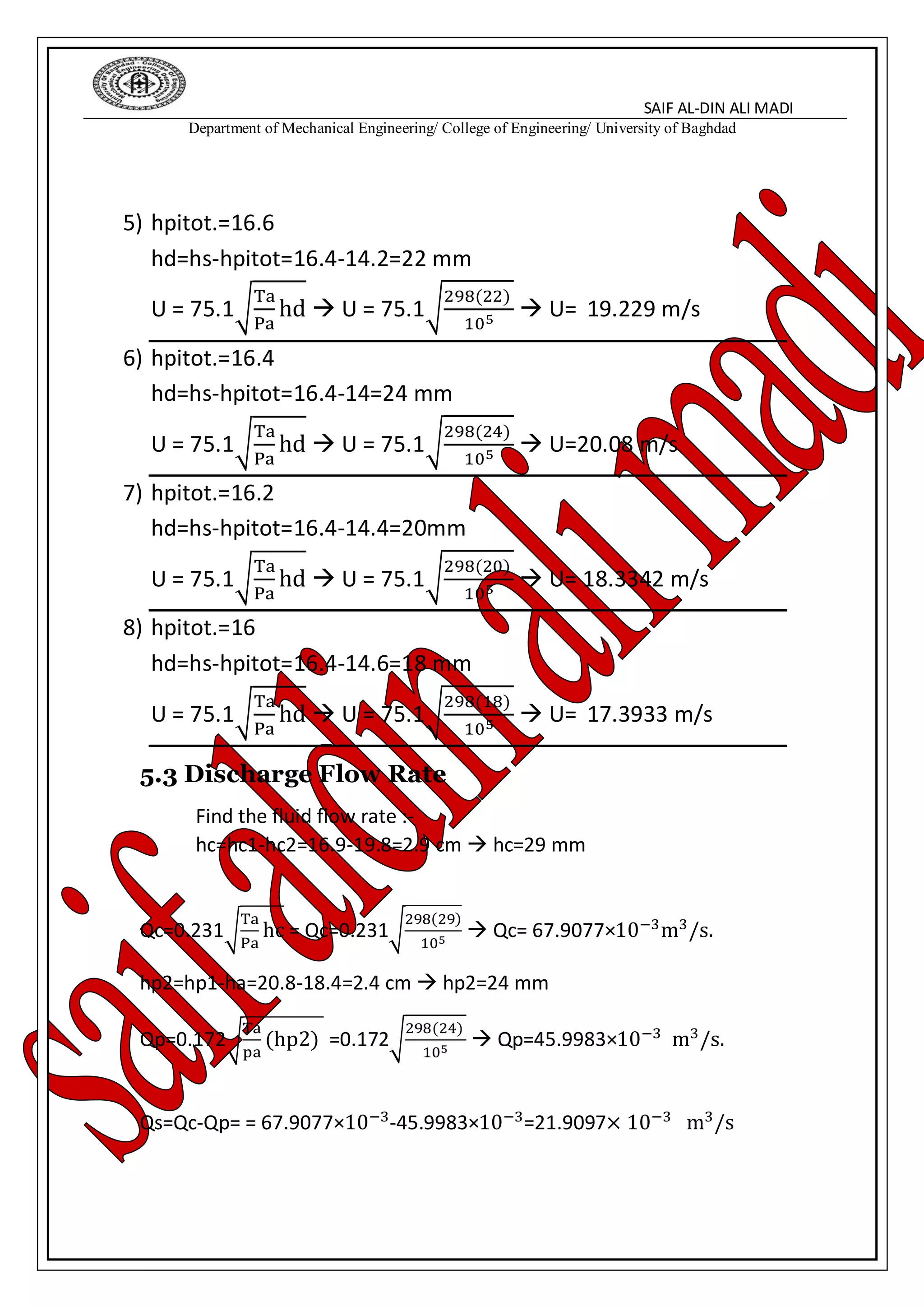

4.3 Discharge Flow Rate

Put the orifice meter in the pipe end to measurement compound flow rate

(secondary + primary), by using the following equation:

Qc = koc

𝛑𝐝𝐨𝐜 𝟐

𝟒

*75.1√

𝐓𝐚 𝐡𝐜

𝐏𝐚[𝟏−(

𝐝𝐨𝐜

𝐝

)

𝟒

]

By using available information you can obtain

Qc=0.231√

𝐓𝐚

𝐏𝐚

𝐡𝐜

Where

hc = orifice head in the end duct (mm)

The same method finds the primary flow rate (Qp):-

Qp=kop

𝛑𝐝𝐨𝐩 𝟐

𝟒

(75.1)√

𝐓𝐚

𝐏𝐚

(𝐡𝐩𝟐)

Qp=0.172√

𝐓𝐚

𝐩𝐚

(𝐡𝐩𝟐)

Where: hp orifice head in the start jet (mm).

4.4 Find the friction Force:-

1. Theoretical analysis

Re =

ρavaD

μa

μa = 1.8 × 10−5

m2

/s

ρa = 1.2 kg/m^3

F = 8TWdx

Ff = πD ∫ TW dx = πDTWl = (

π

8

1

0

)fpauc

2 Dl

Ff =

2fρa Qc

2

l

πD3](https://image.slidesharecdn.com/inducedflow-181109205459/75/Induced-flow-Fluid-Laboratory-U-O-B-18-2048.jpg)

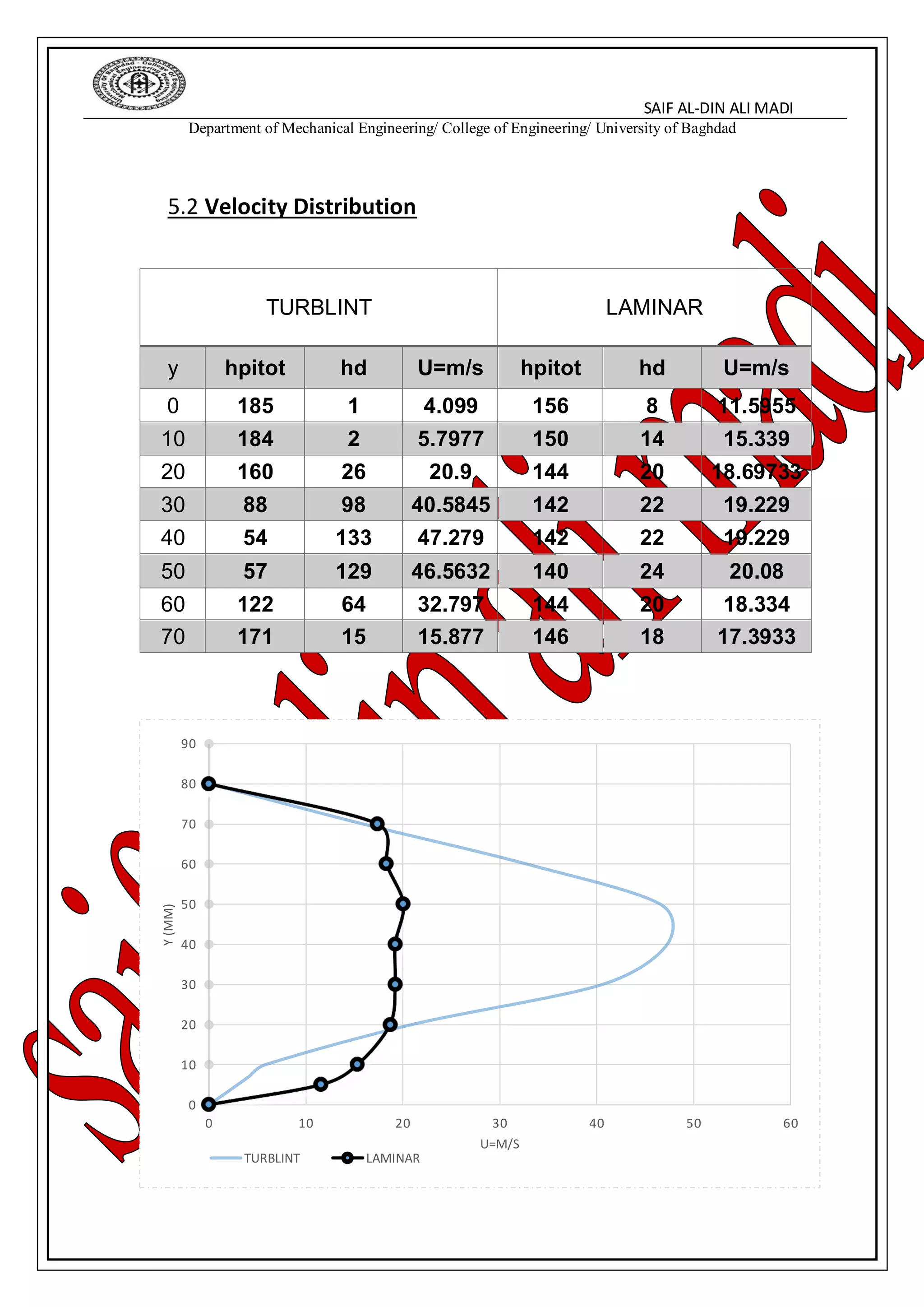

![SAIF AL-DIN ALI MADI

Department of Mechanical Engineering/ College of Engineering/ University of Baghdad

v2 =

2pwg hd

fa 103

}/R

v2

R

=

2pwg hd

fa 103R

∵

Ta

Pa

=

1

pa

v2

R

=

2pwg hd

fa 103R

∗

Ta

𝛒 𝐚a

v = √

2 ∗ 1000 ∗ 9.81 ∗ 287

103

Ta

𝛒 𝐚

hd

v = 75.1√

Ta

𝛒 𝐚

hd

B. equation 5

Qc = kc

πdC

2

4

75.1√

Ta hc

ρa[1 − (

dC

2

D

)4]

Qc = 0.64 ∗

3.14(66 ∗ 10−3)2

4

∗ 75.1√

Ta hc

ρa[1 − (

66 ∗ 10−3

79 ∗ 10−3)4]

Qc =

0.6574

4

∗ √

Ta hc

ρa[0.5128]

Qc =

0.6574

4

∗ √

Ta hc

ρa[0.5128]

Qc =

0.6574

2.864

∗ √

Ta

ρa

hc

Qc = 0.231 ∗ √

Ta

ρa

hc](https://image.slidesharecdn.com/inducedflow-181109205459/75/Induced-flow-Fluid-Laboratory-U-O-B-29-2048.jpg)