The document outlines a laboratory experiment on the function and characteristics of various governors, specifically focusing on the porter governor. It explains the theory and principles of governors used for speed regulation in engines, along with experimental procedures, calculations, and results obtained from testing different governor configurations. The report includes detailed measurements and analysis of governor performance at various speeds.

![Saif al-din ali Madi

Department of Mechanical Engineering/ College of Engineering/ University of Baghdad

2-5-2019 1 | P a g e

[theory of machine Laboratory II]

University of Baghdad

Name: - Saif Al-din Ali -B-](https://image.slidesharecdn.com/governorapparatus-190703191316/75/Governor-apparatus-theory-of-machine-Laboratory-1-2048.jpg)

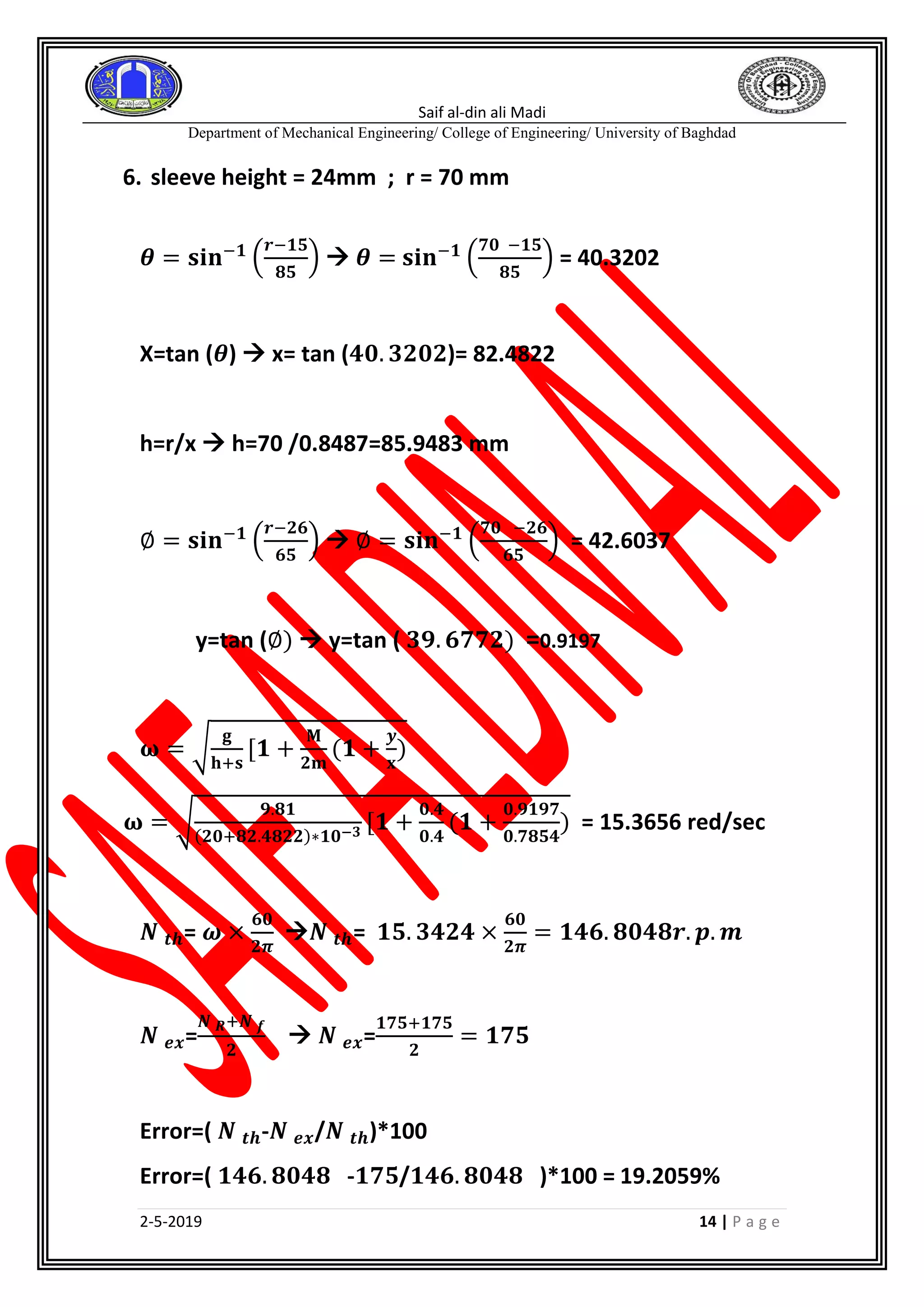

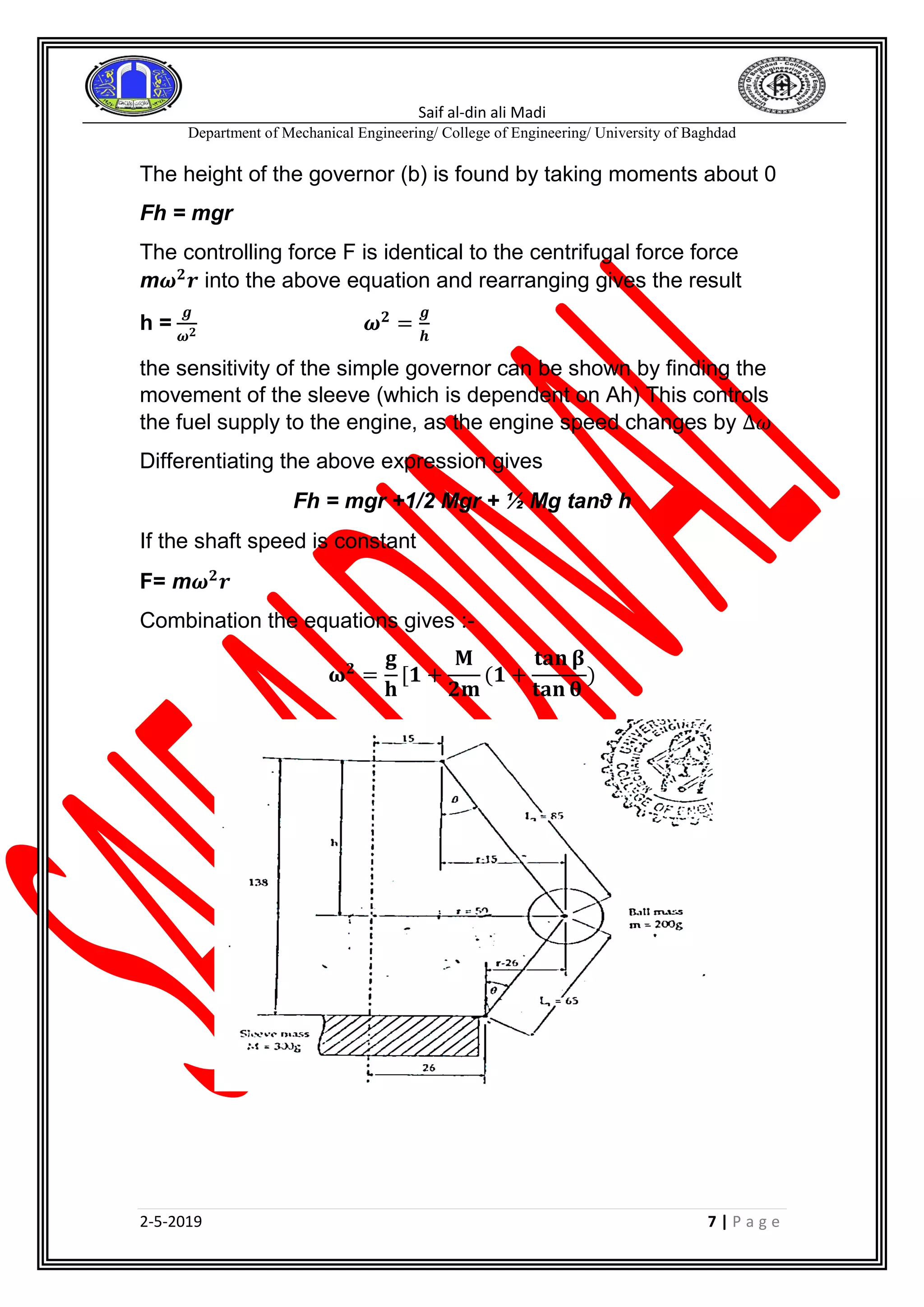

![Saif al-din ali Madi

Department of Mechanical Engineering/ College of Engineering/ University of Baghdad

2-5-2019 8 | P a g e

Derivation of Porter speed equation

∑ 𝑴𝑰 = 𝟎

Fc* AD -mg ID –

𝑴𝒈

𝟐

∗ 𝑰𝑪 = 𝟎 ÷ 𝑨𝑫

Fc = mg

𝑰𝑫

𝑨𝑫

+

𝑴𝑮

𝟐

∗

𝑰𝑪

𝑨𝑫

= 𝒎𝒈𝐭𝐚 𝐧 𝜽 +

𝑴𝒈

𝟐

(𝐭𝐚 𝐧 𝜽 + 𝐭𝐚 𝐧 𝝋)

Since Fc = m𝝎 𝟐

𝒓

m𝝎 𝟐

𝒓 = mg

𝒓

𝒉

+

𝑴𝒈

𝟐

𝒓

𝒉

( 𝟏 +

𝐭𝐚 𝐧 𝝋

𝐭𝐚 𝐧 𝜽

)

Thus:-

𝛚 𝟐

=

𝐠

𝐡

[𝟏 +

𝐌

𝟐𝐦

(𝟏 +

𝐭𝐚𝐧 𝛃

𝐭𝐚𝐧 𝛉

)

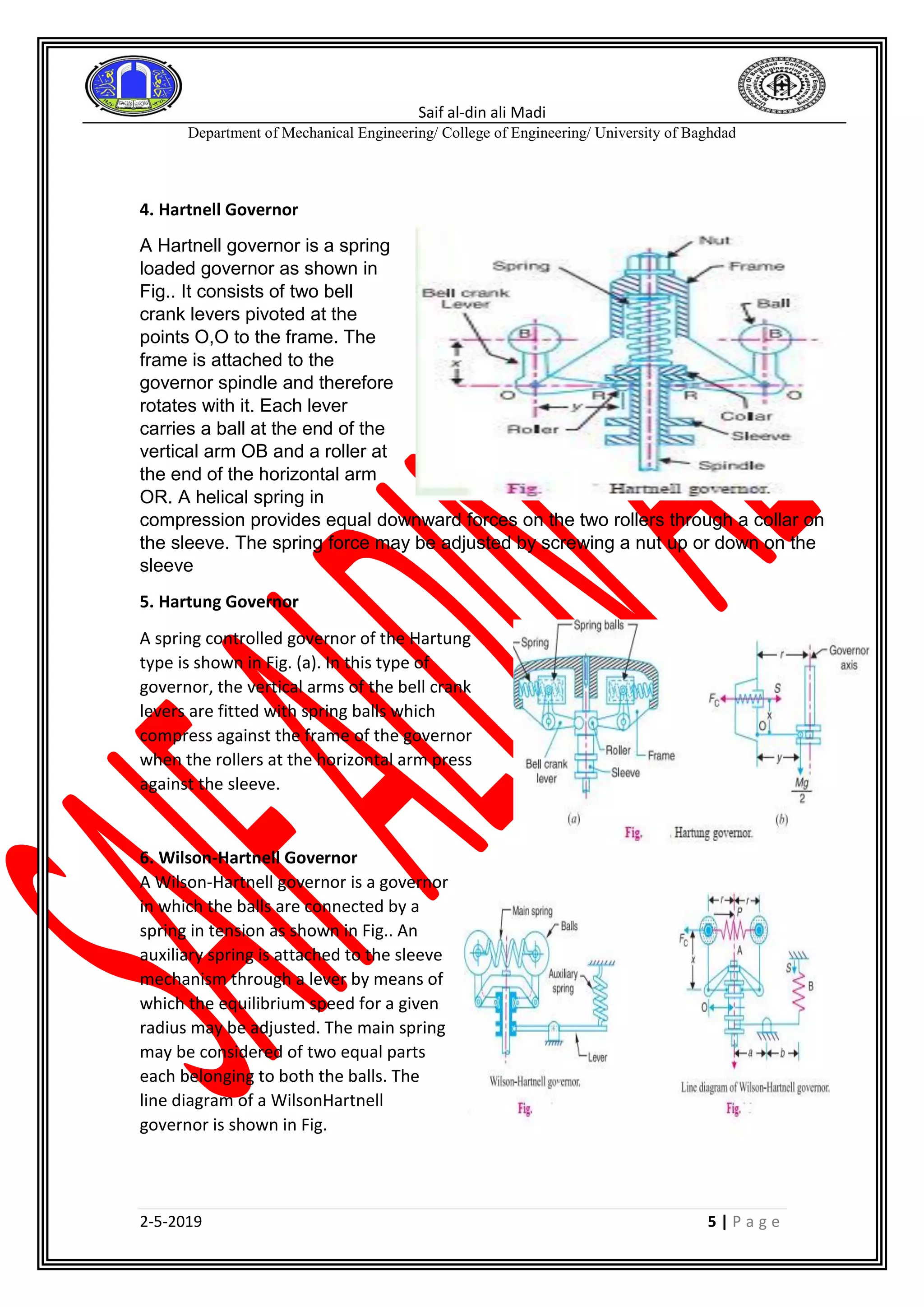

Proell Governor

ThePROELL governor is similar to the Porter governor

except that the governor ball balls fixed to extensions of the links,

as shown in Figure 3. The arm reacts shaft pivot with a force T1.

As with the Porter governor, the reaction of the link on t sleeve

(T2) can be resolved into a vertical component ½ Mg and a

horizontal component H.

Ti and H need not be calculated if moments are taken about the

Point O

𝑭 𝒀 = 𝒎𝒈(𝒙 − 𝒓) +

𝟏

𝟐

𝑴𝒈(𝒙 − 𝒃)

Also, if the shaft speed is steady. F is given by Equation 2.5

F=m𝝎 𝟐

𝒓

An expression for co as a function of y can be found by combining

Equations 2.5 and 2.9. Hences

𝝎 𝟐

= [(𝒙 − 𝒓) +

𝑴

𝟐𝒎

(𝒙 − 𝒃)] ×

𝒈

𝒚. 𝒓](https://image.slidesharecdn.com/governorapparatus-190703191316/75/Governor-apparatus-theory-of-machine-Laboratory-8-2048.jpg)