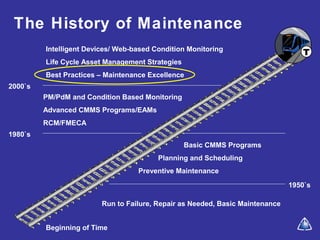

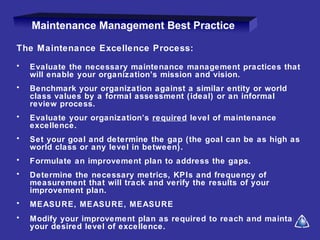

This document discusses maintenance management best practices and the journey towards maintenance excellence. It provides an overview of the history and evolution of maintenance from run-to-failure approaches to modern condition-based monitoring and asset management strategies. The document outlines steps in the process for evaluating an organization's current maintenance practices, setting goals for improvement, identifying metrics to track progress, and modifying plans to achieve a desired level of maintenance excellence. Specific examples are provided for calculating common best practice metrics using a computerized maintenance management system.