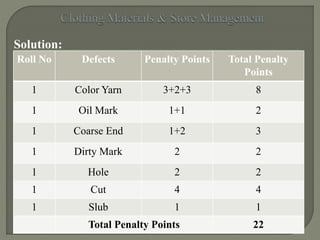

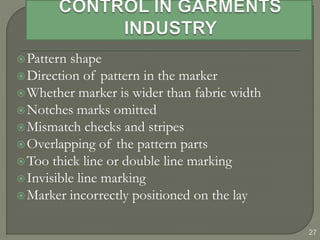

This document discusses quality and quality control in manufacturing. It defines quality as meeting standards and customer requirements without defects. Quality control aims to identify defects in finished products through activities like inspections, while quality assurance prevents defects through process management. The document outlines quality control steps and areas to monitor like materials, cutting, sewing and finishing to ensure product quality. It provides details on inspection methods, defect tracking and process improvement.