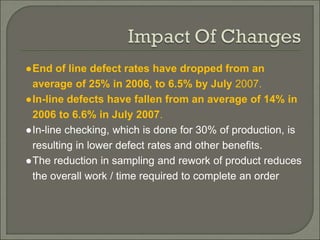

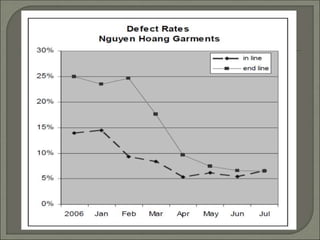

Nguyen Hoang Exim is a garment manufacturer in Vietnam that was experiencing high defect rates, around 20% total. They lacked a testing and inspection plan and only did quality checks at the end of the production line. With help from the International Labour Organization, they implemented in-line quality checks every two hours, provided more detailed technical instructions, and developed quality control forms. These changes reduced defect rates to 6.5% by July 2007 and improved productivity.