Embed presentation

Downloaded 42 times

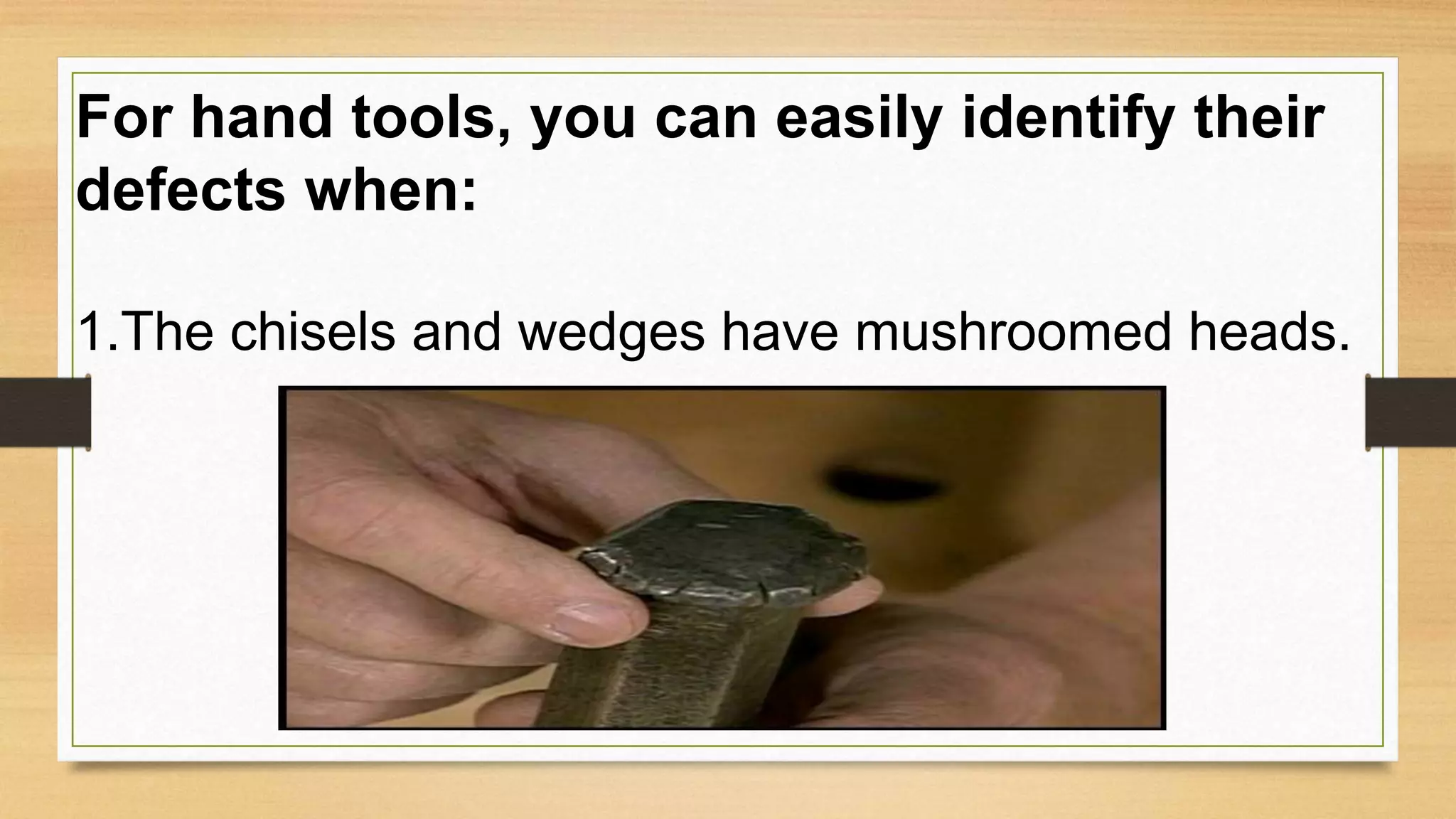

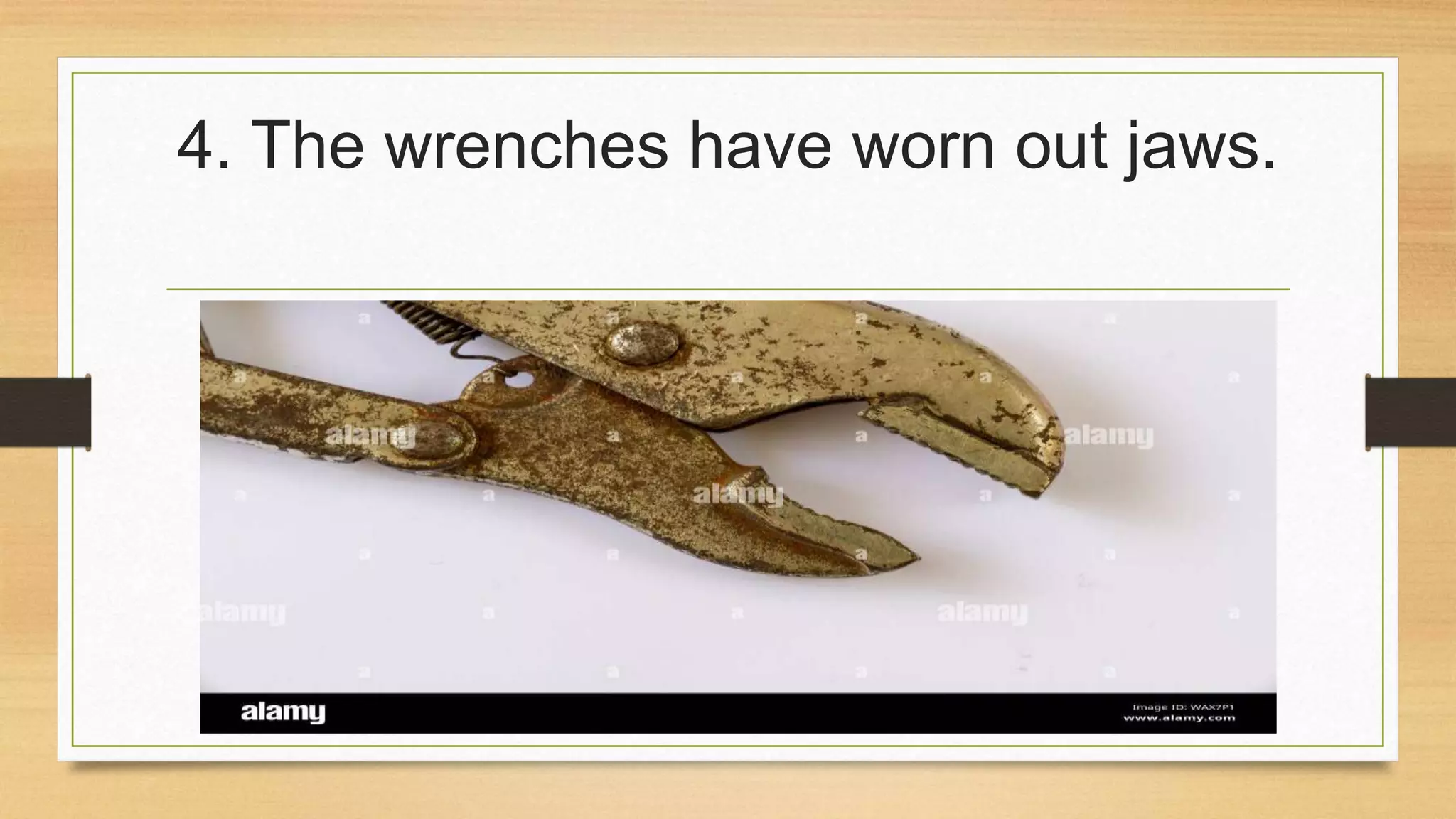

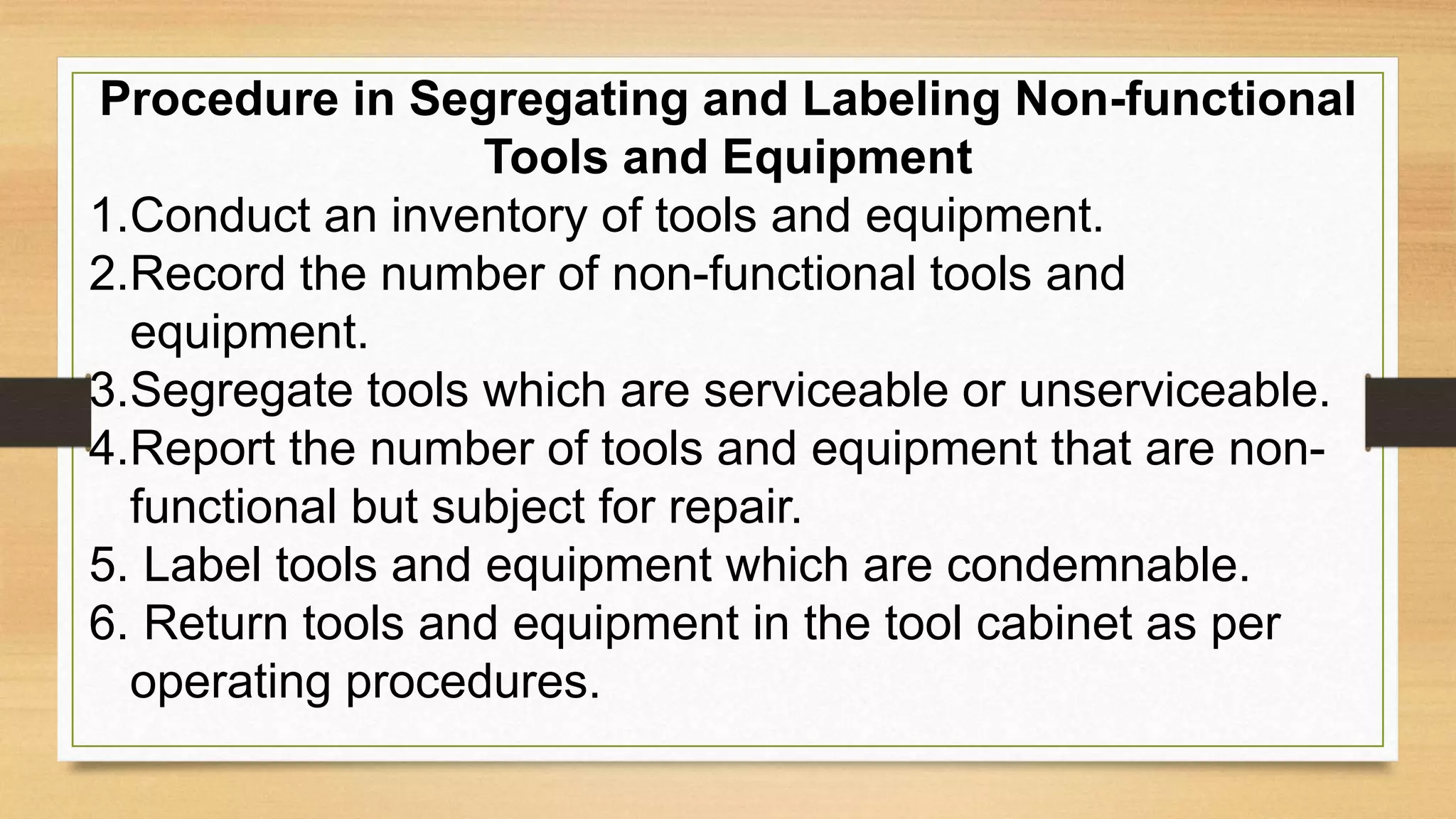

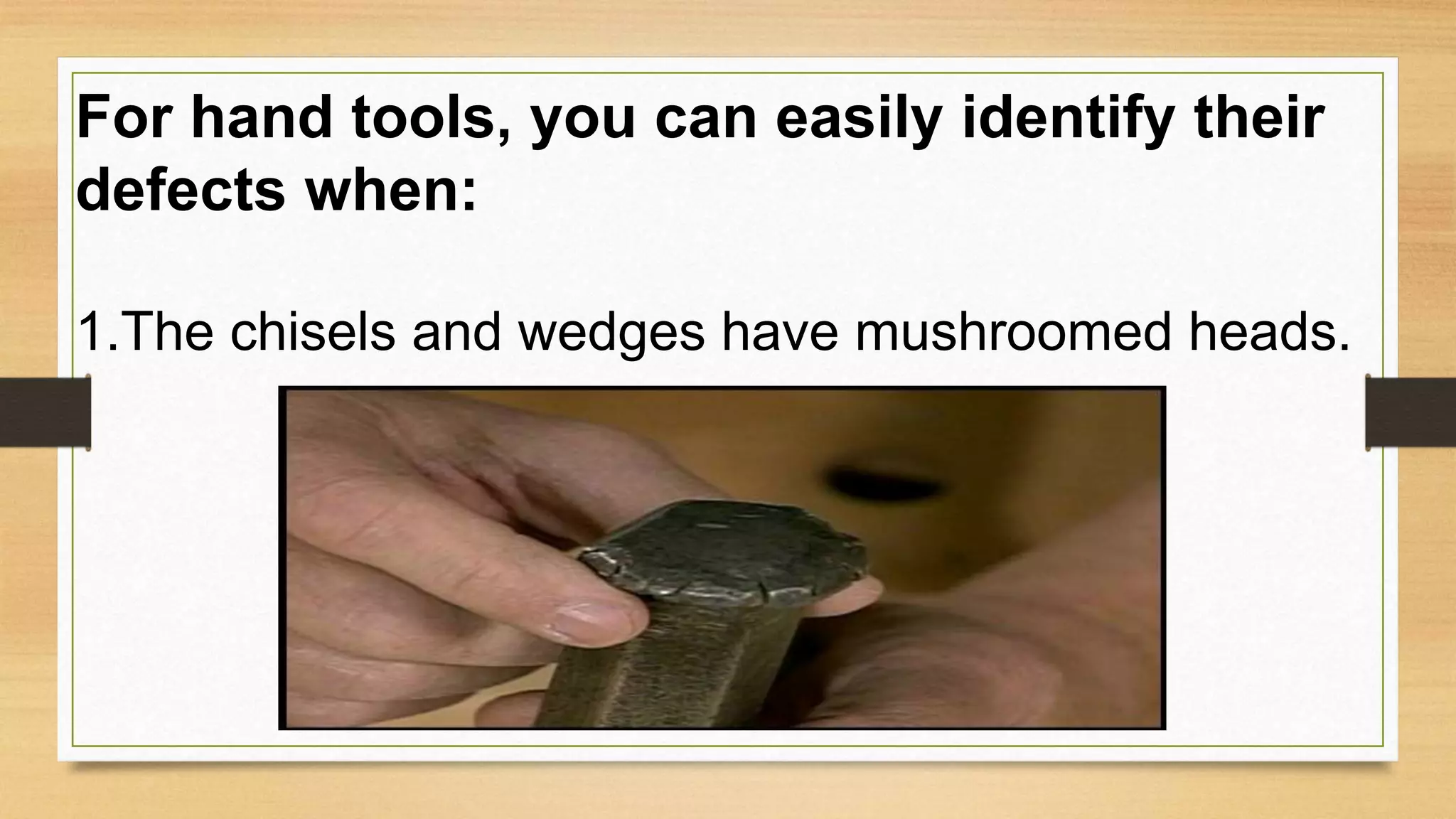

Defective hand tools can be identified if they have mushroomed chisel heads, cracked or split handles, or chipped drill bits. Power tools may be defective if they are missing or broken guards, have damaged grounding due to insulation issues, or have worn out blades or non-functional switches. Tools and equipment should be inventoried and sorted as functional, needing repair, or condemned, then properly stored or repaired. Personal protective equipment should also be inspected, tested, and repaired or replaced if non-functional.