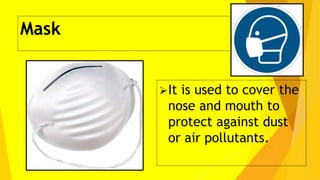

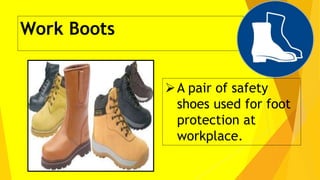

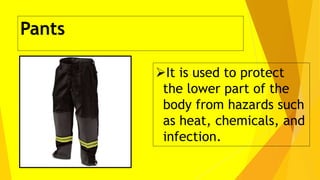

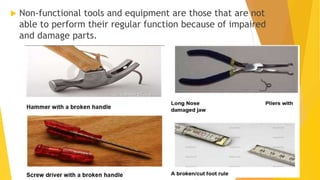

Personal protective equipment (PPE) is used to protect workers from hazards in the workplace. Common types of PPE mentioned include hard hats to protect the head from falling objects, gloves to protect hands from cuts and burns, goggles to prevent eye injuries from flying particles, and masks to protect from dust or air pollutants. Other PPE includes work boots, pants, and assignments to define hazards like chemical, psychological, biological, ergonomic and physical hazards. Tools are classified as functional or non-functional based on visual inspections and whether they perform their intended functions properly. Tools are also classified based on their uses such as measuring, holding, cutting, driving, boring, and electrical equipment.