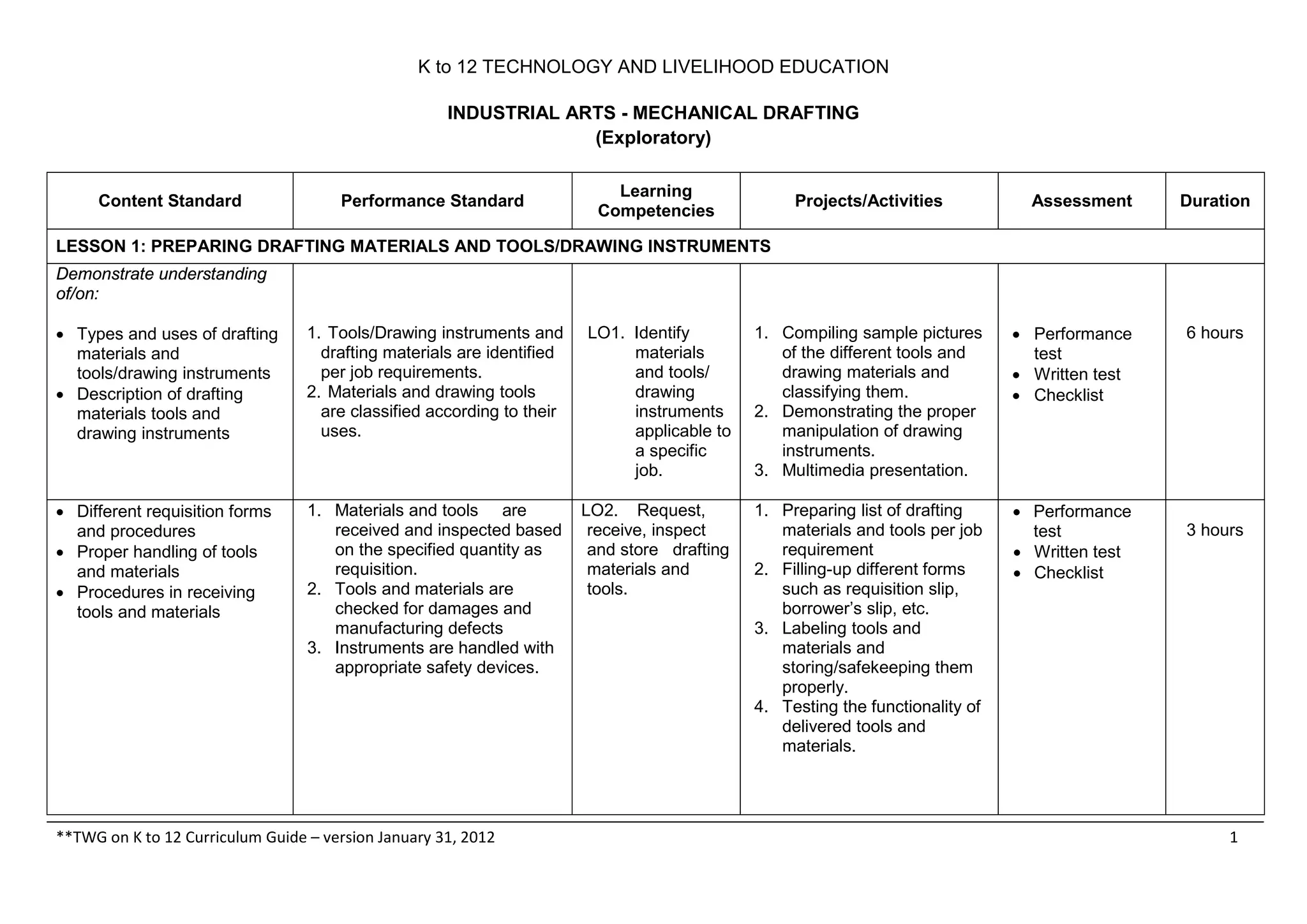

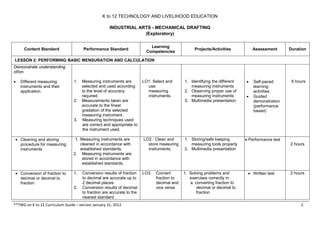

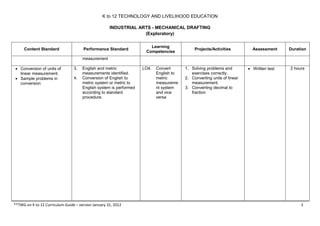

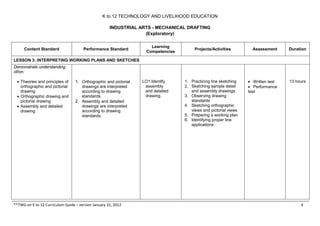

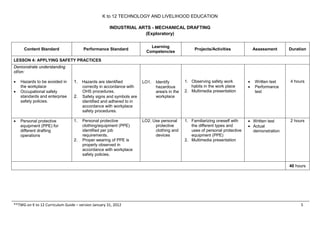

This document provides a curriculum for an exploratory course on mechanical drafting. It outlines 4 lessons that will be covered over 40 hours. Lesson 1 covers drafting materials, tools, and instruments. Lesson 2 focuses on basic measurement and calculation. Lesson 3 is about interpreting working plans and sketches. Finally, Lesson 4 addresses applying safety practices, including identifying hazards and using personal protective equipment. Each lesson has specific learning competencies, projects/activities, and assessment methods. The goal is for students to gain understanding and skills related to mechanical drafting foundations.