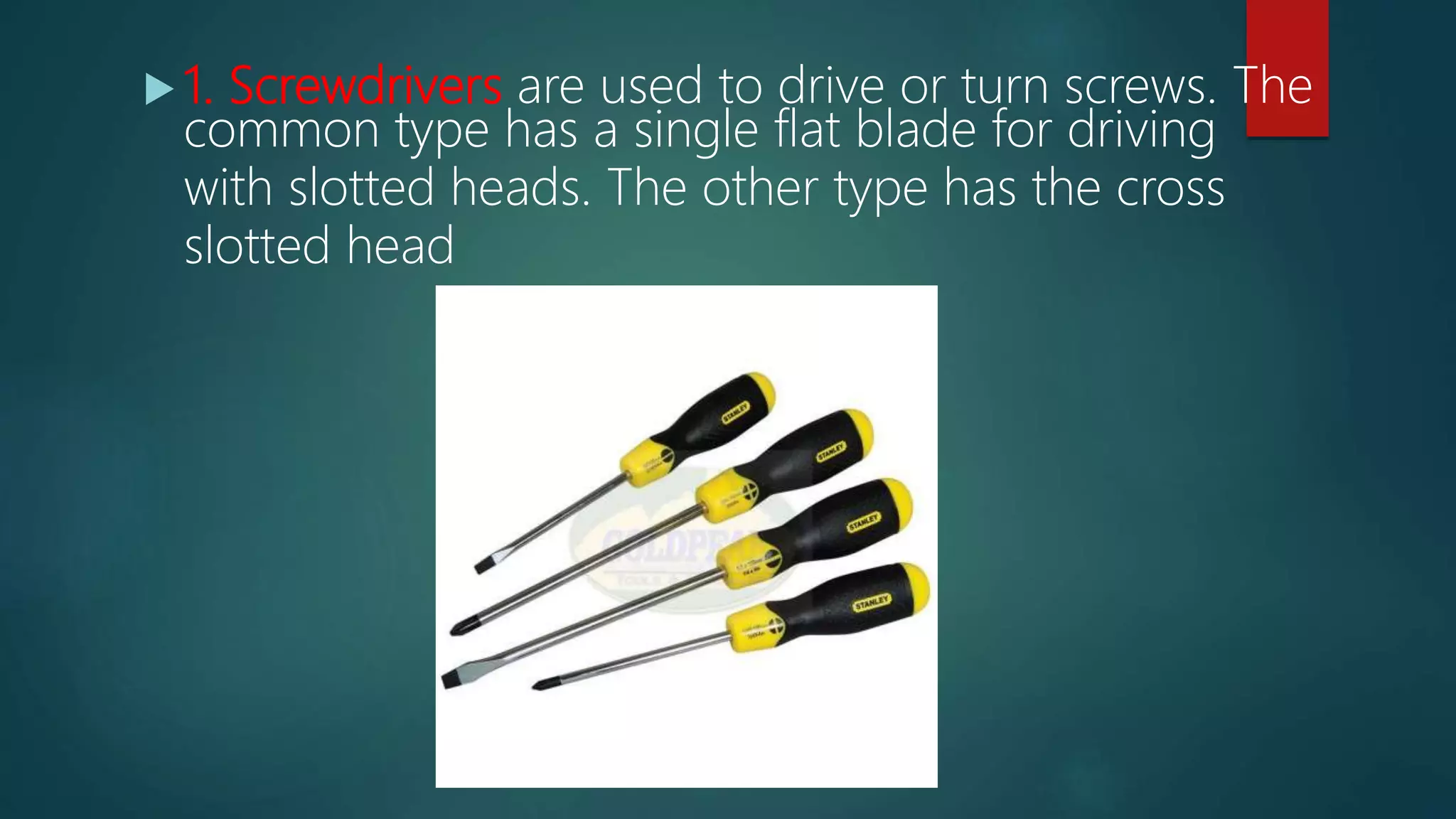

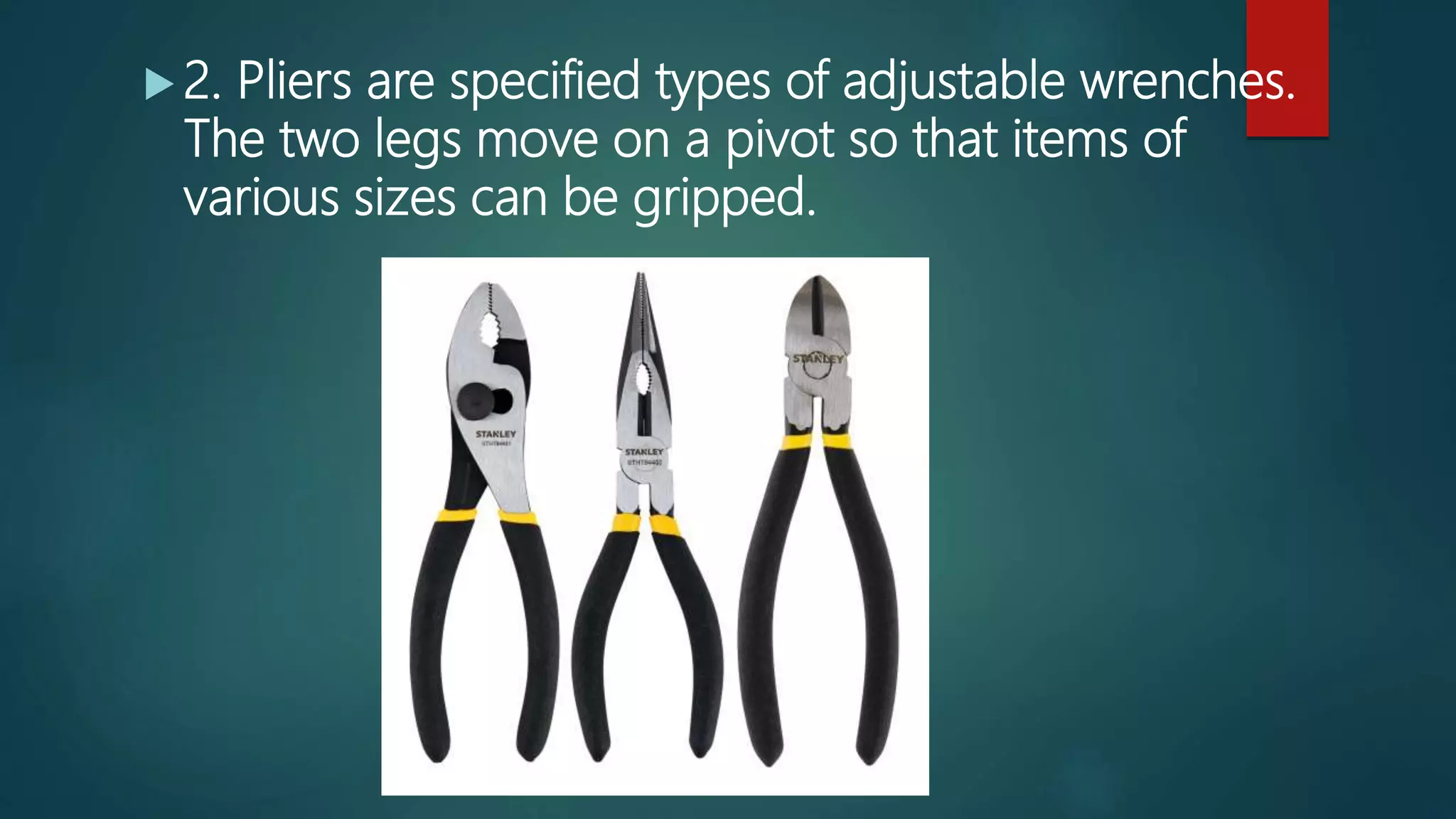

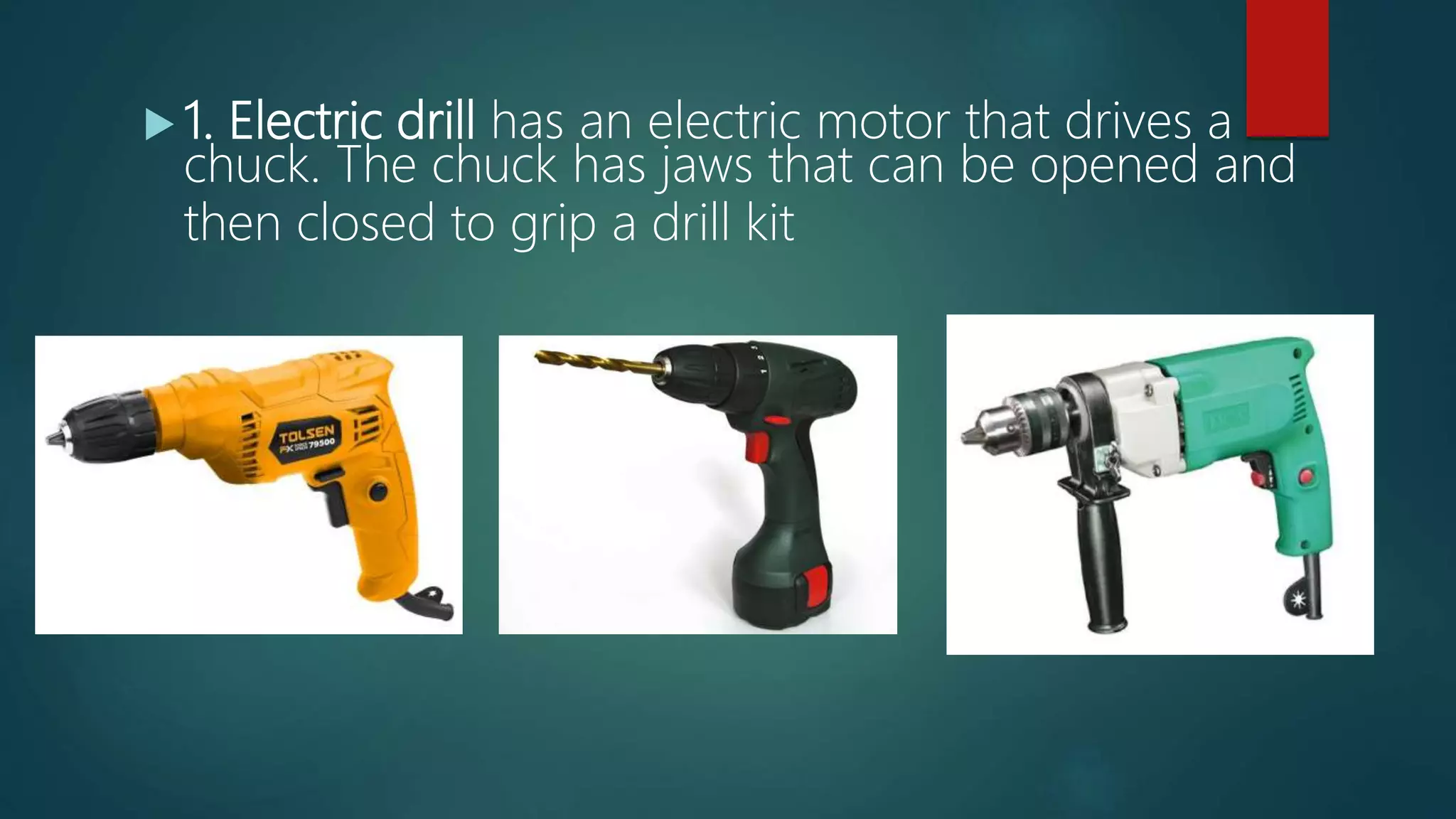

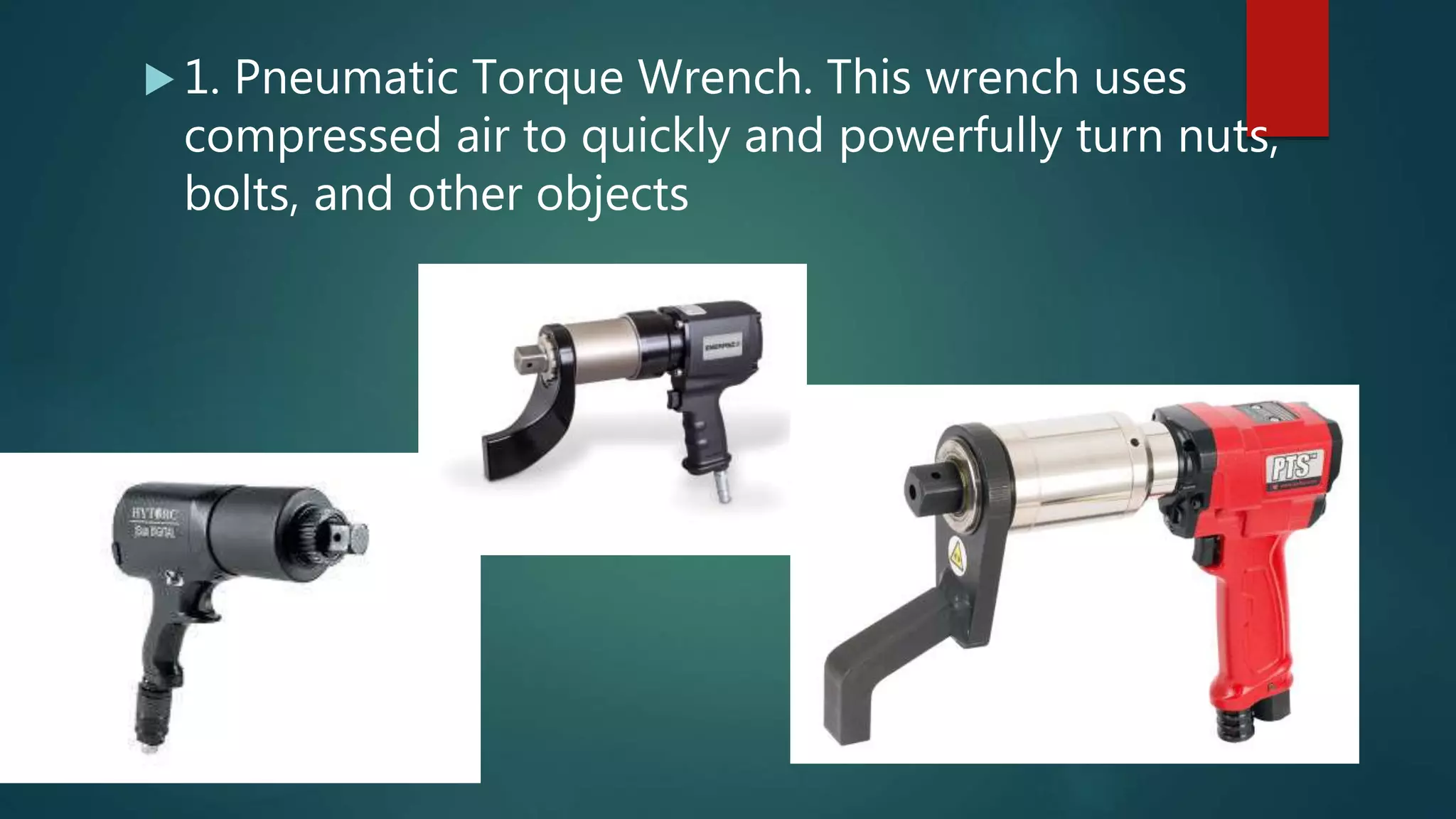

The document discusses the classification, maintenance, and identification of tools and equipment. It separates tools into three main categories: hand tools, power tools, and pneumatic tools. It provides examples for each category and outlines best practices for maintaining electrical tools, such as cleaning dust, inspecting cords, and proper storage. The document also discusses identifying non-functional tools through visual inspection, checking functionality and performance, power supply, and input from experienced personnel. Non-functional tools are those unable to perform their regular functions due to damaged or impaired parts.