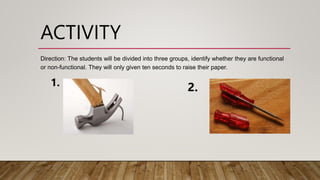

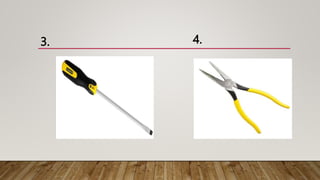

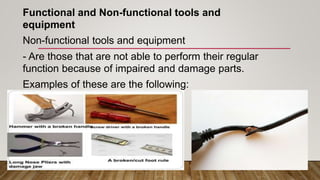

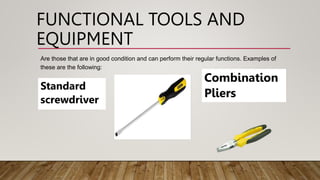

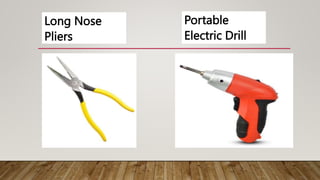

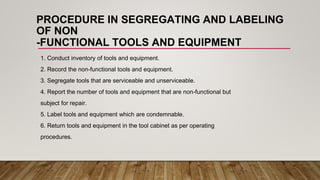

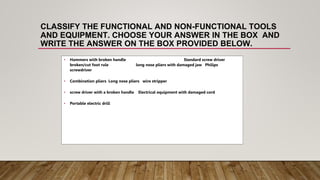

The document outlines learning objectives for identifying and classifying functional and non-functional tools and equipment. It includes a group activity for students to determine tool status, explains the importance of distinguishing between the two types, and provides methods for identifying non-functional tools. A procedure for segregating and labeling non-functional tools and equipment is also detailed.