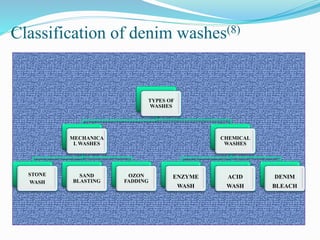

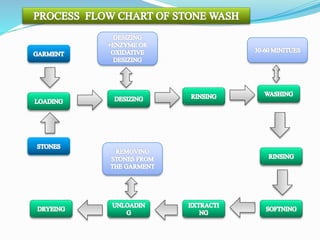

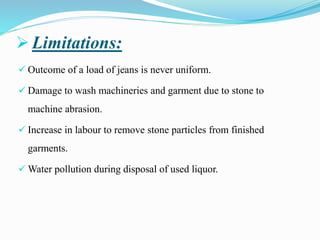

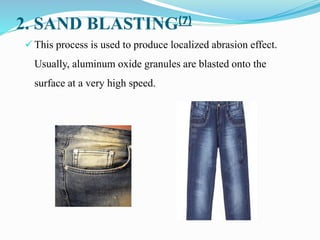

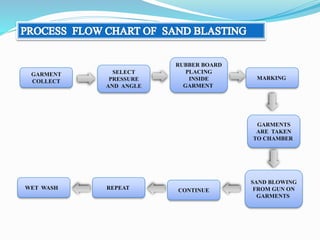

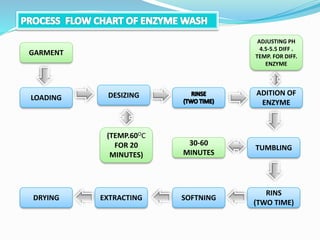

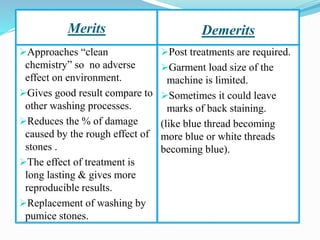

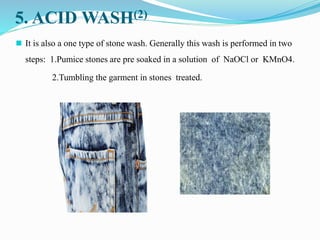

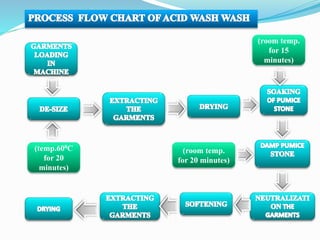

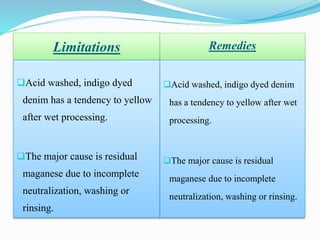

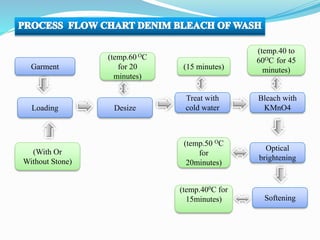

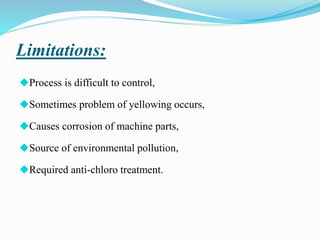

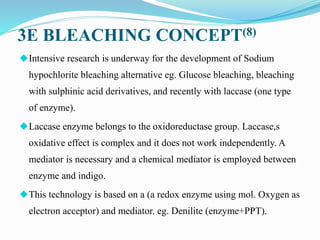

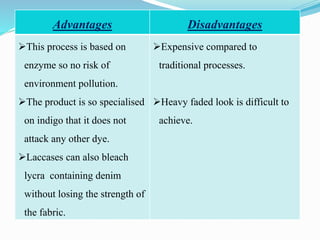

This document discusses various methods for washing denim fabrics. It begins by introducing denim and its traditional dyeing process. It then outlines the objectives of denim washing such as creating faded effects, increasing softness, and improving quality. The document categorizes washes as mechanical (stone, sandblasting, ozone fading) or chemical (enzyme, acid, bleach). For each wash type, it provides details on the process and discusses advantages and limitations. It concludes by listing references used in the document.