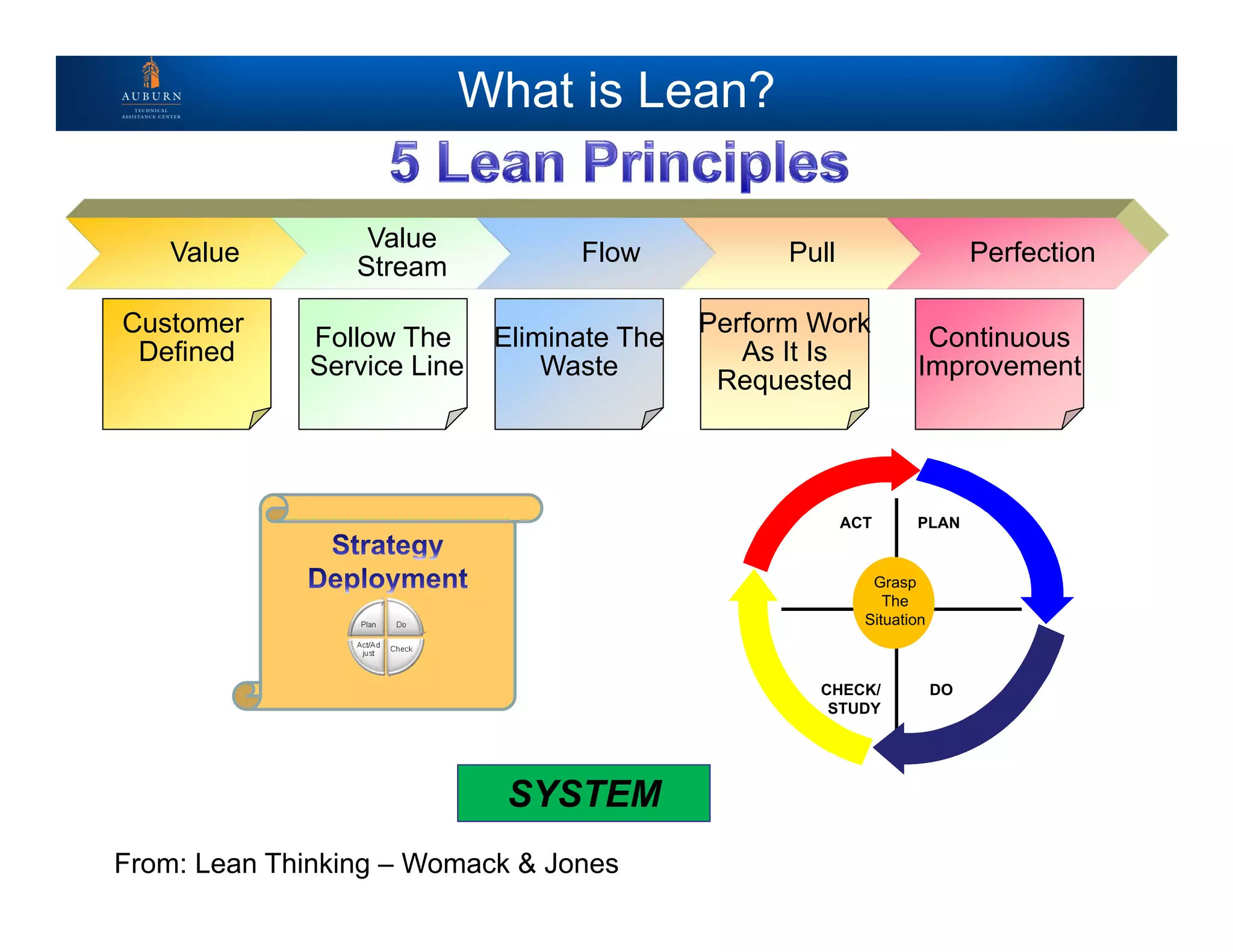

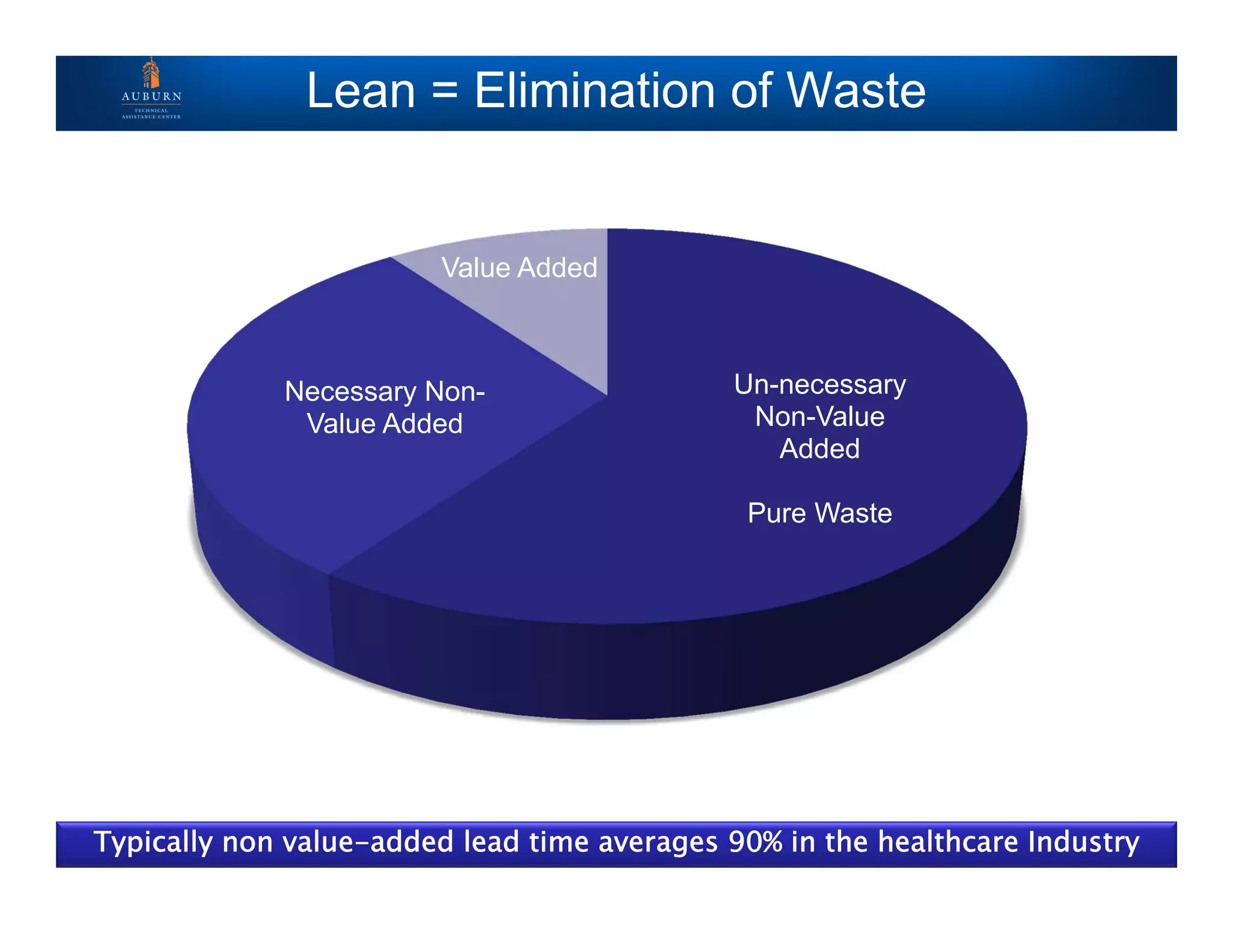

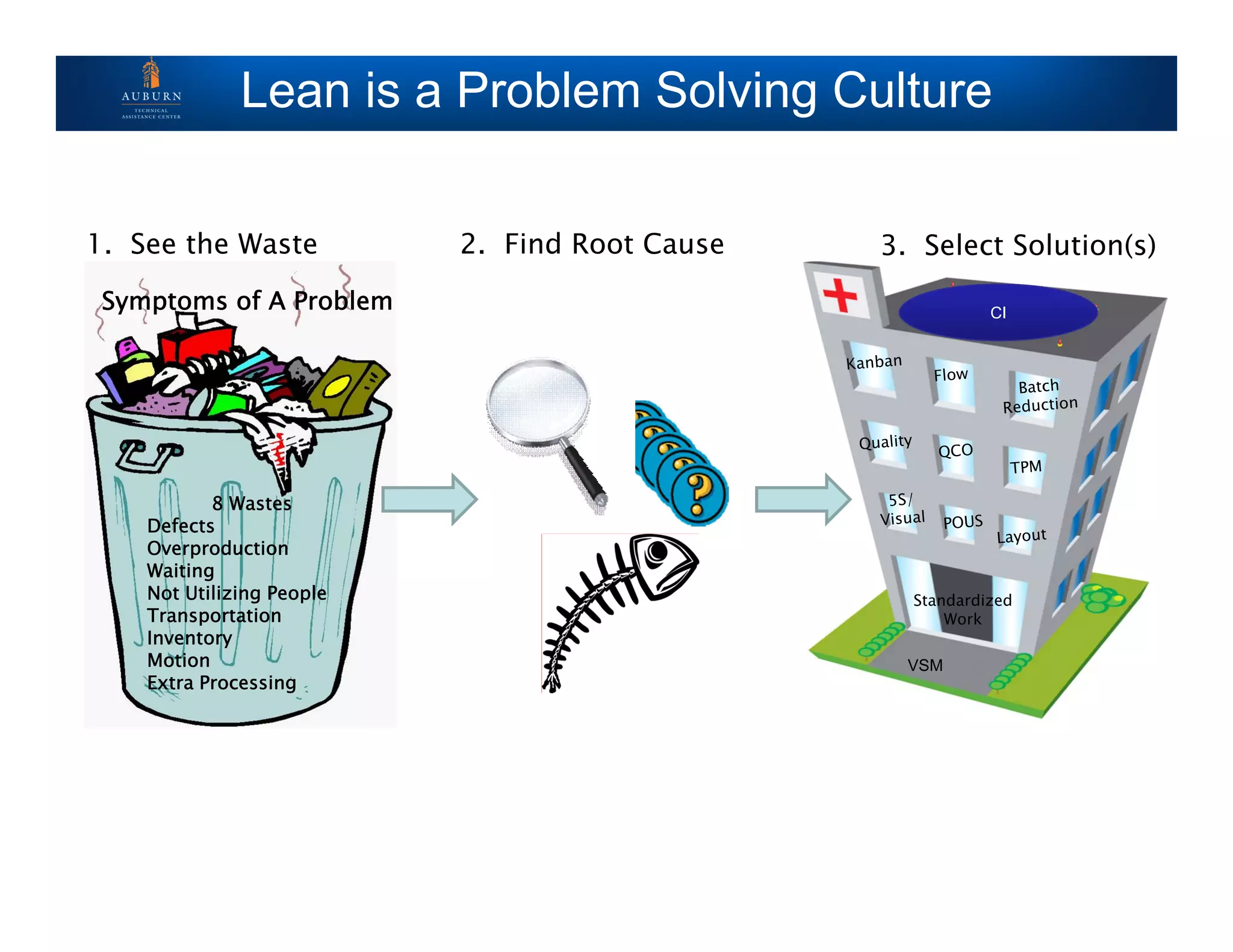

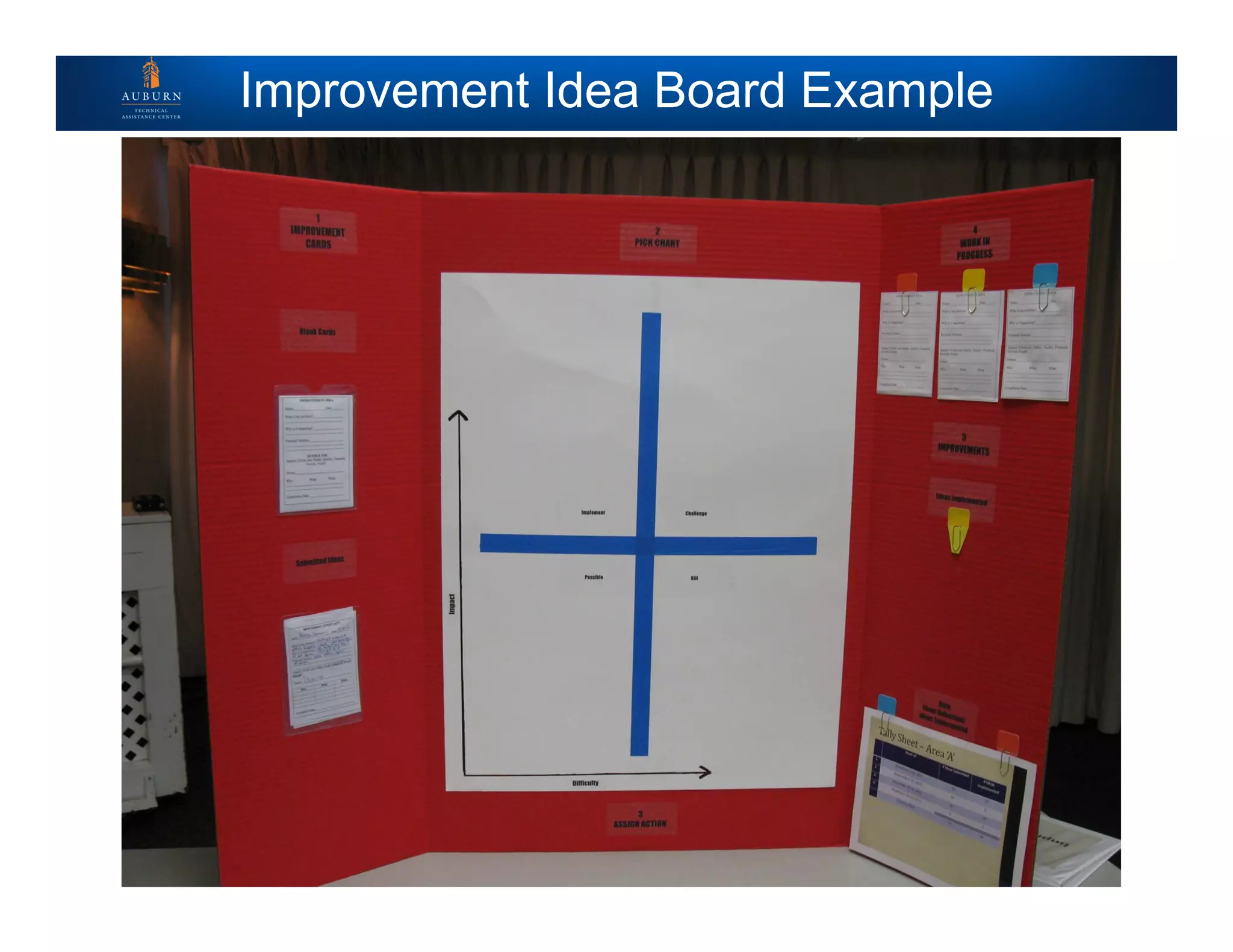

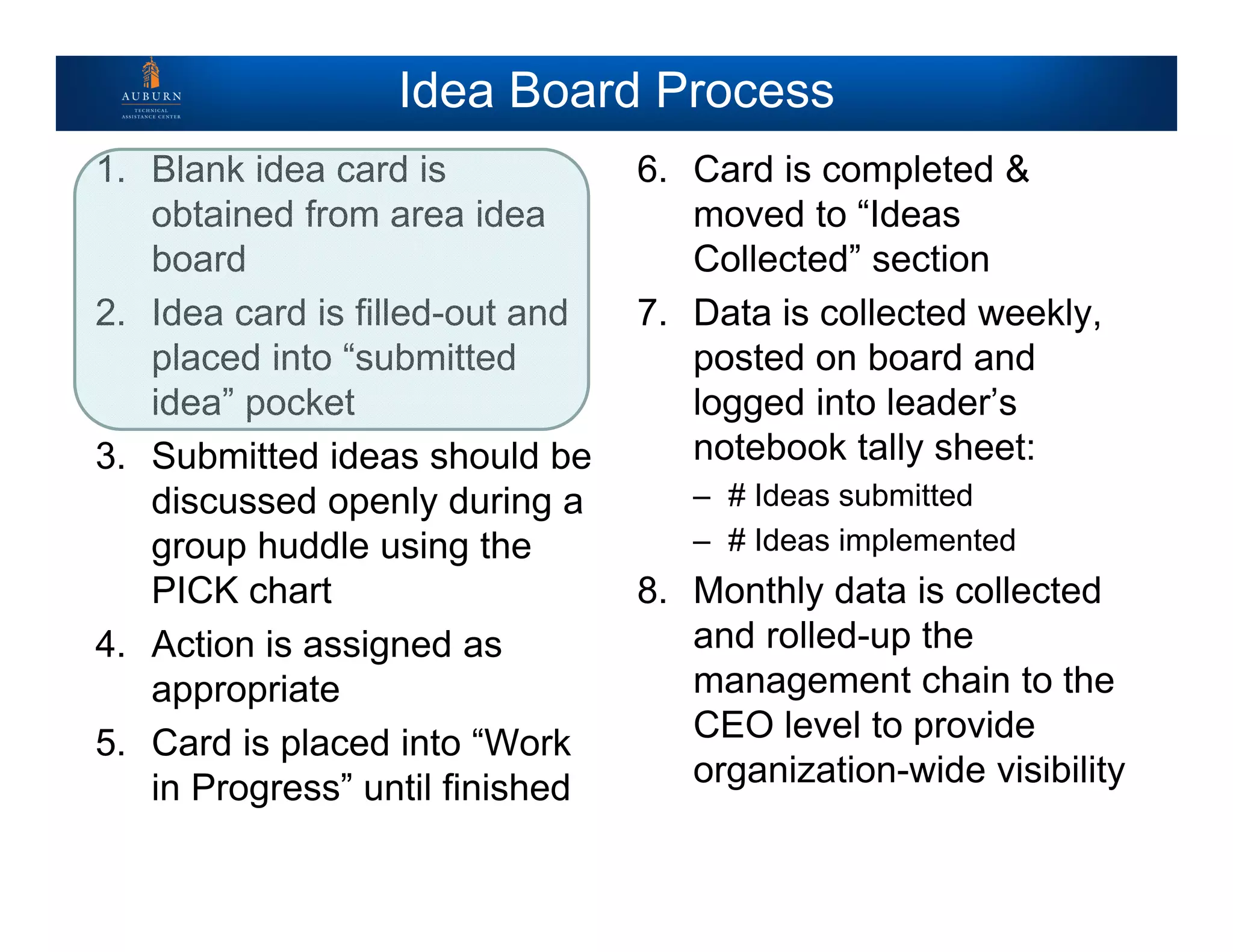

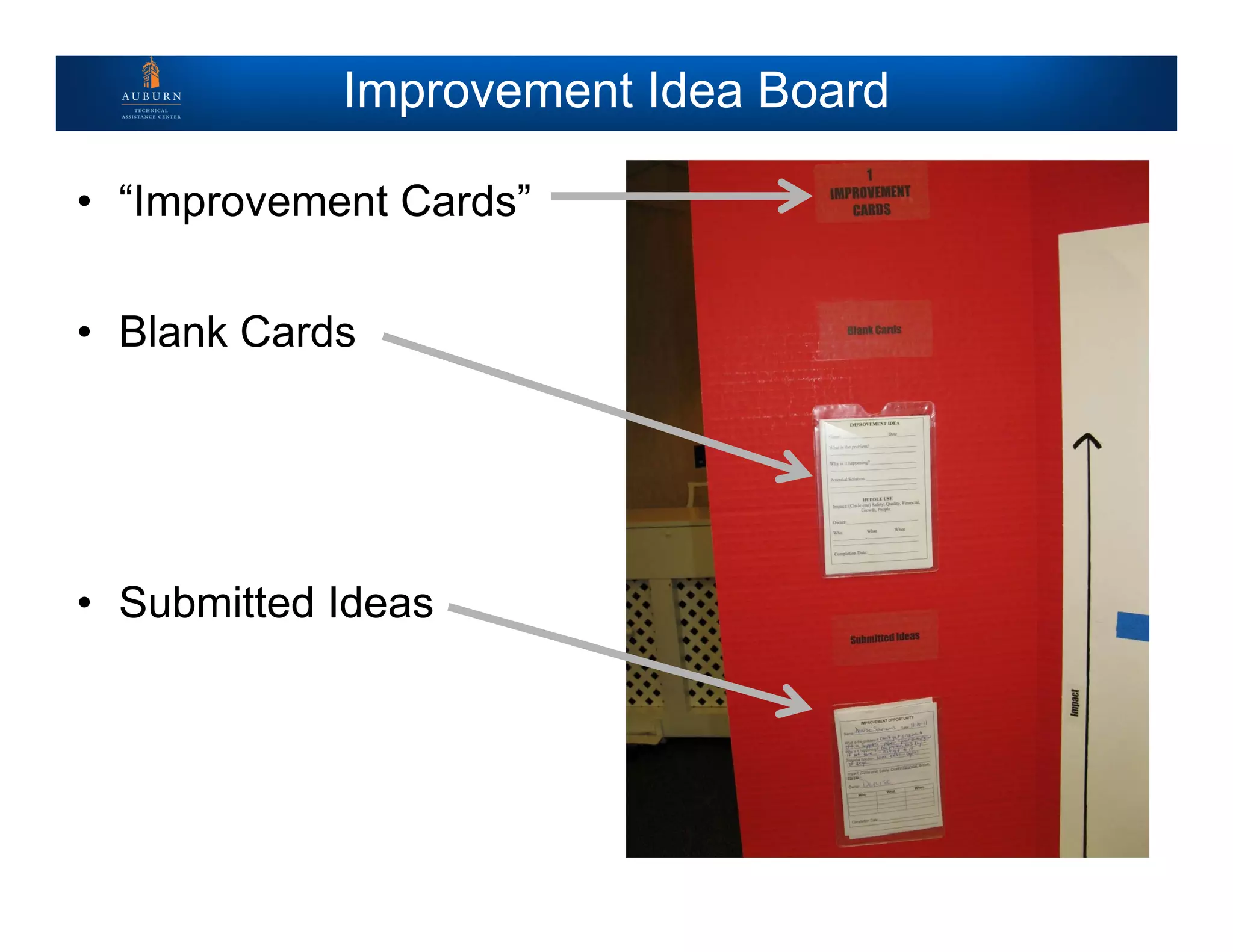

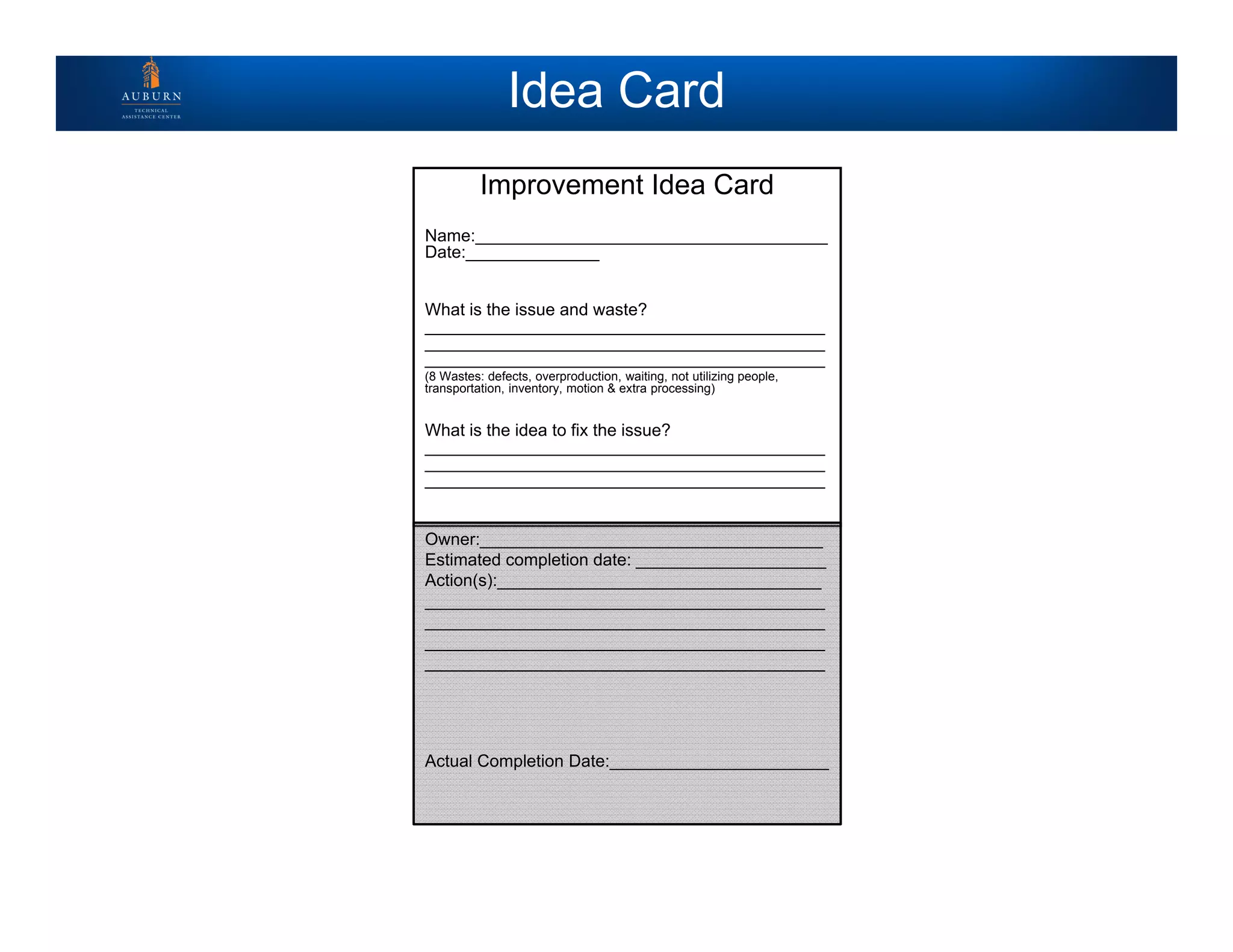

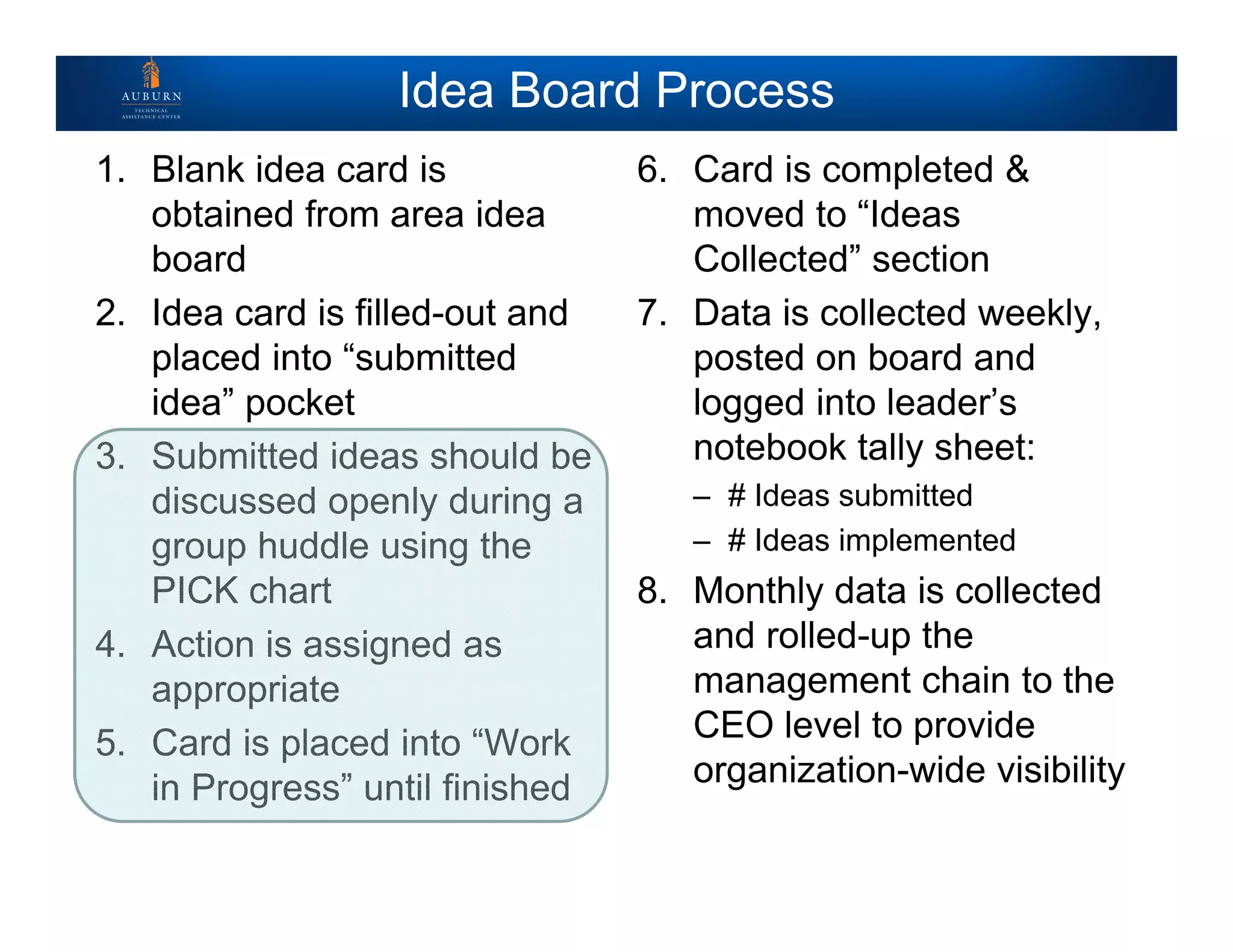

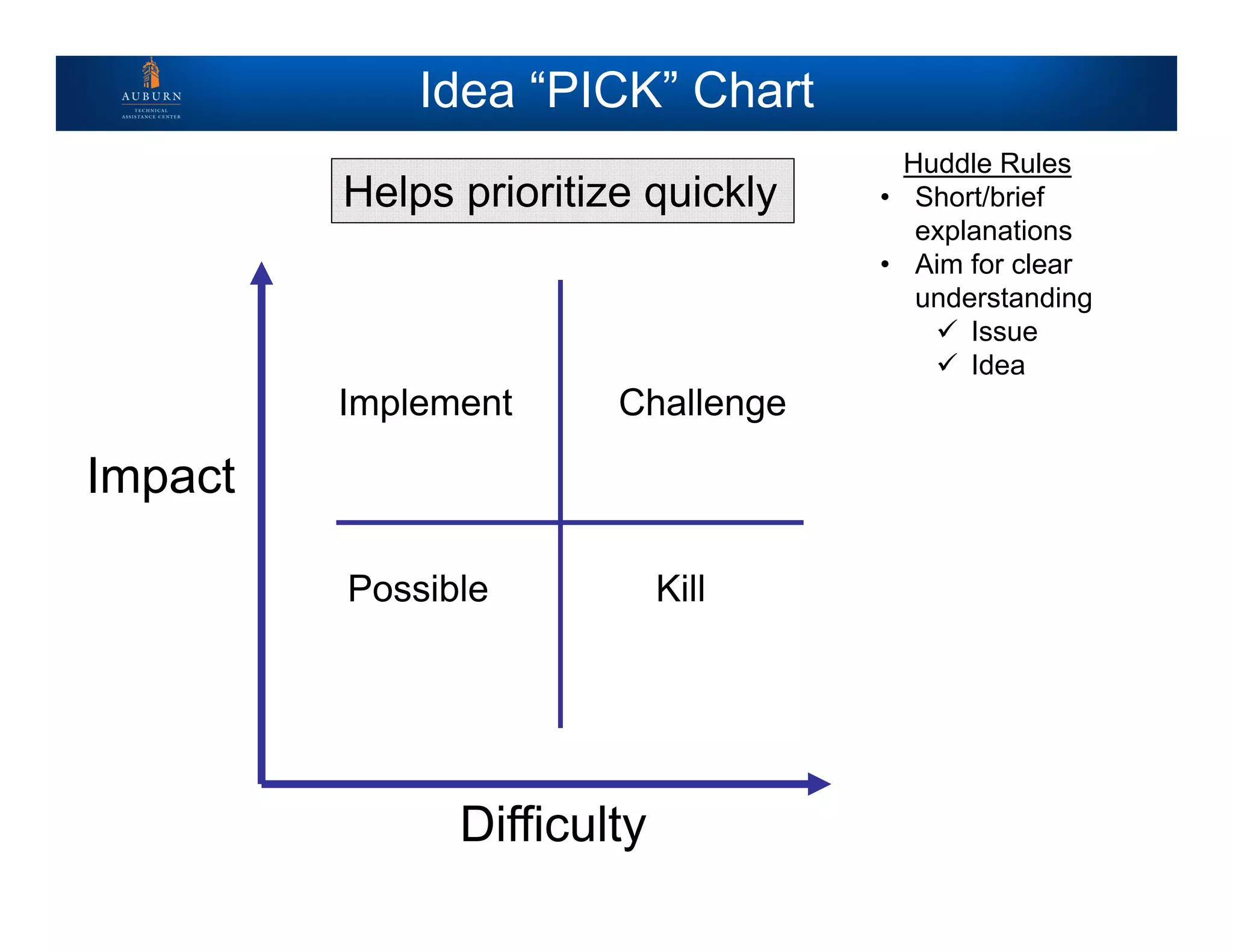

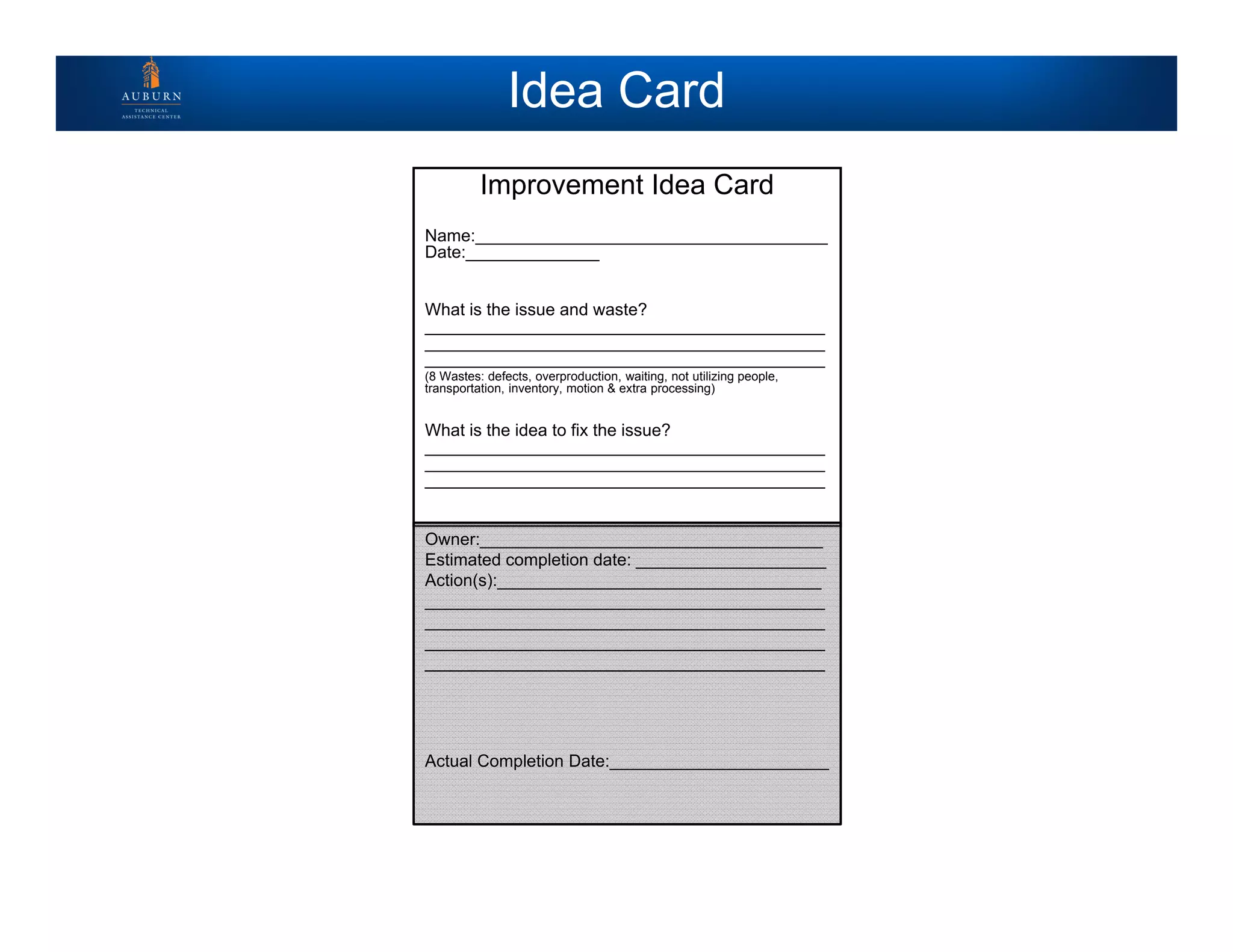

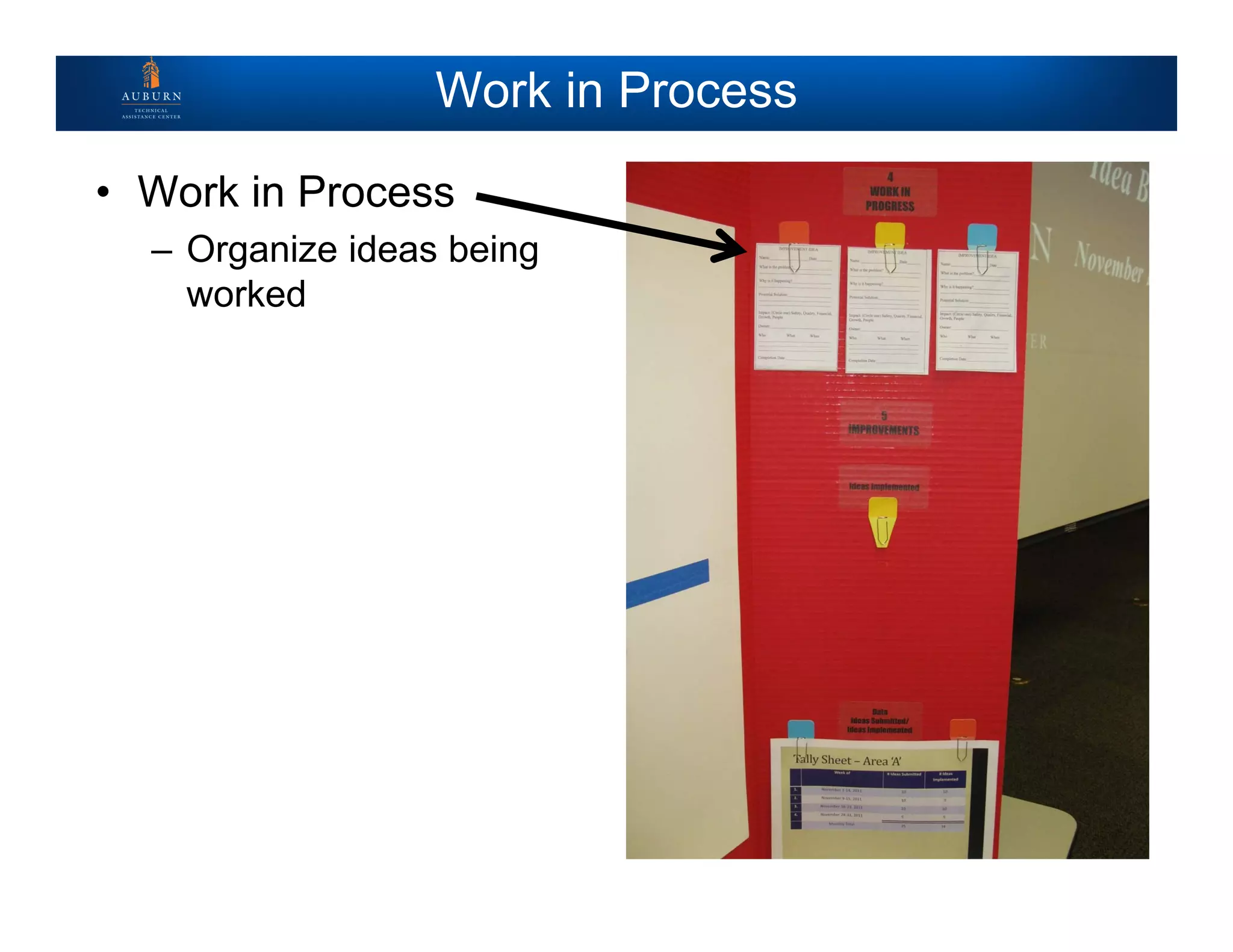

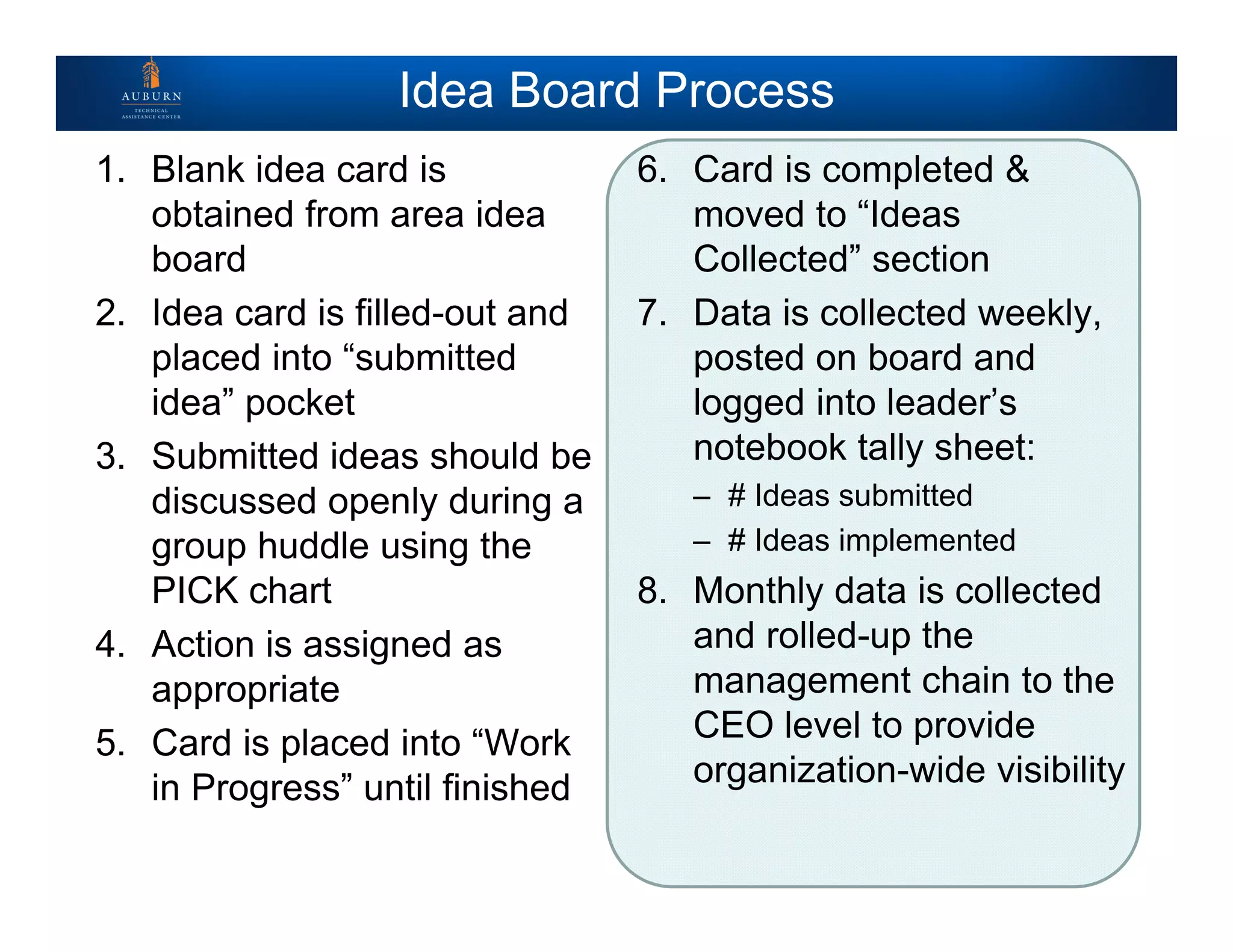

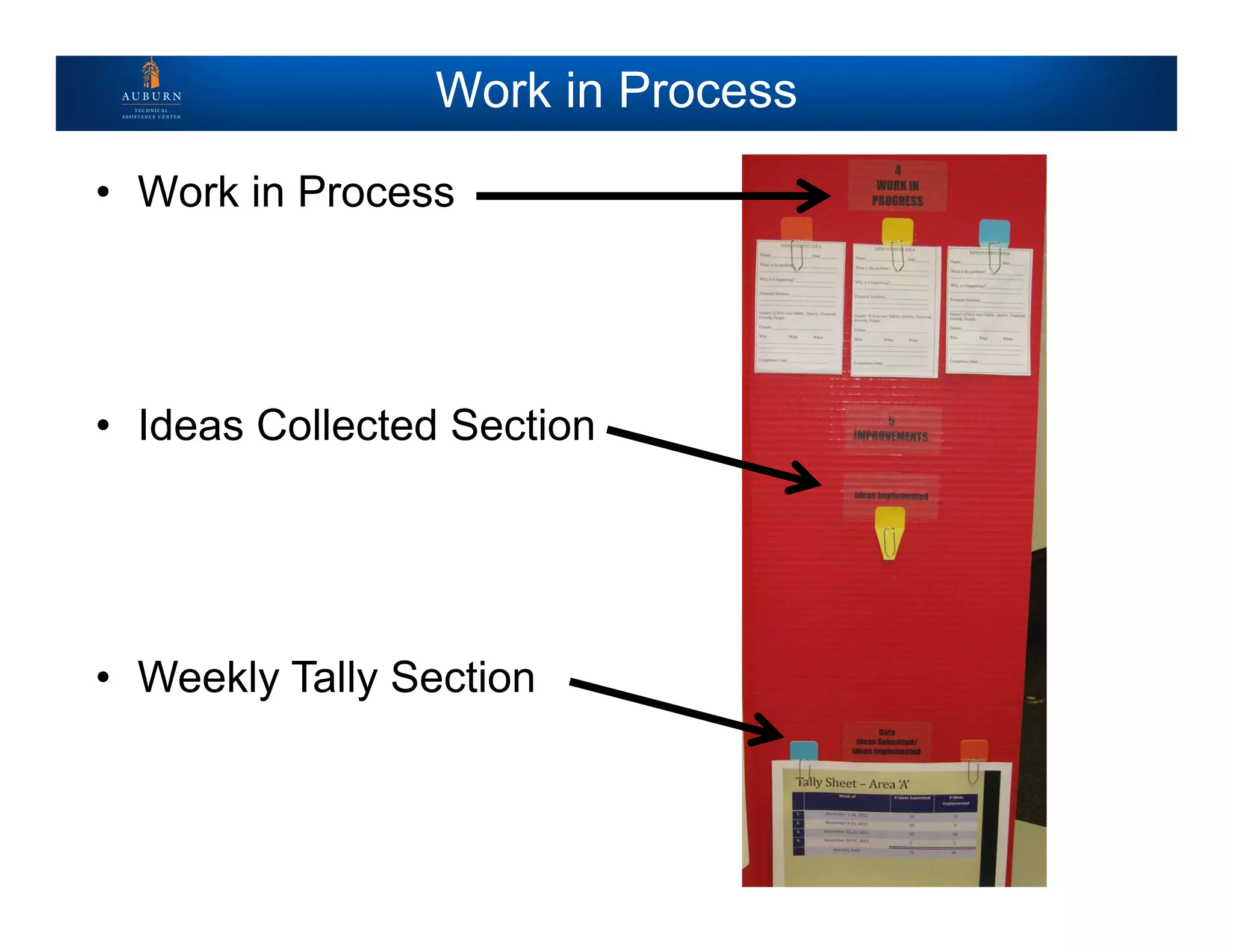

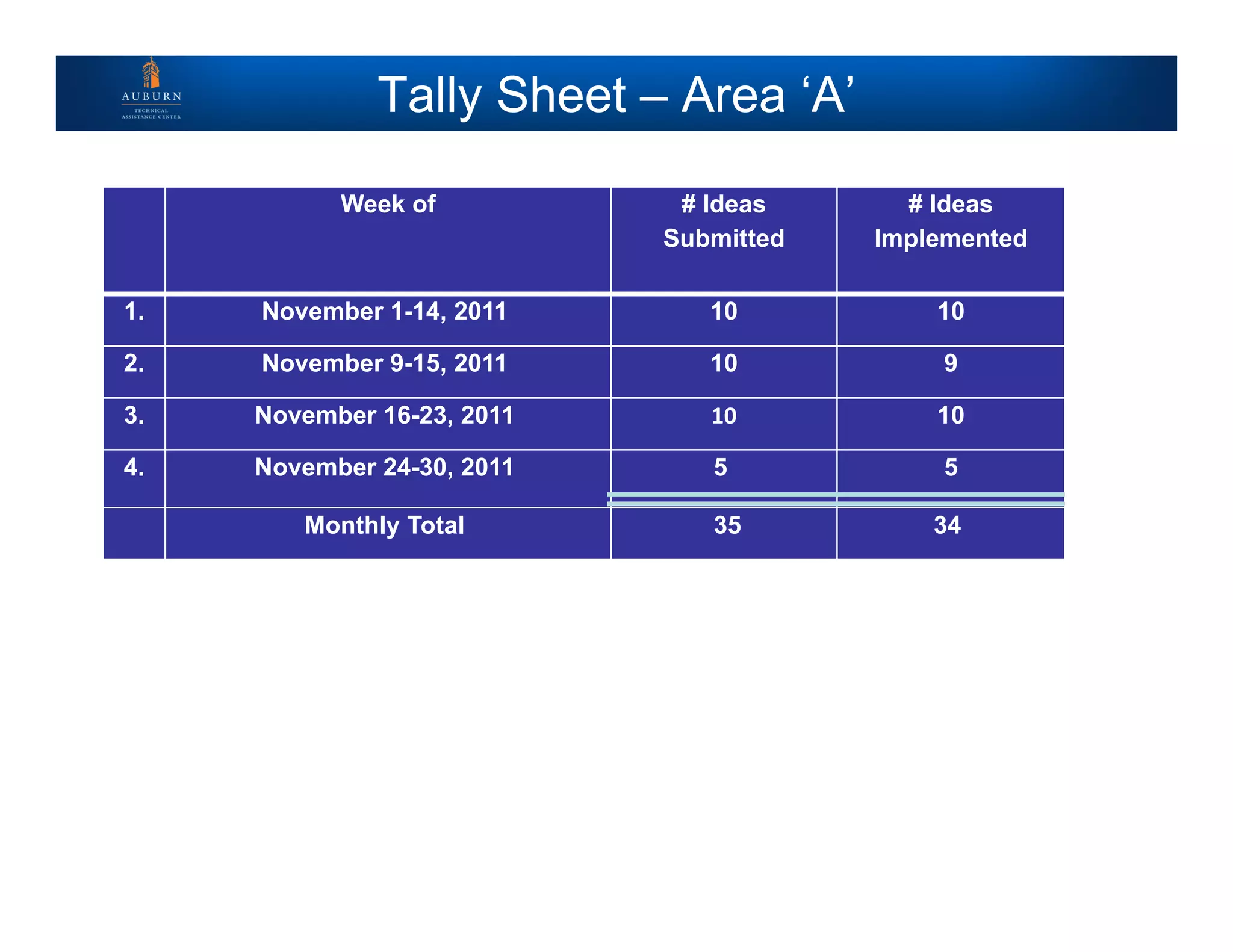

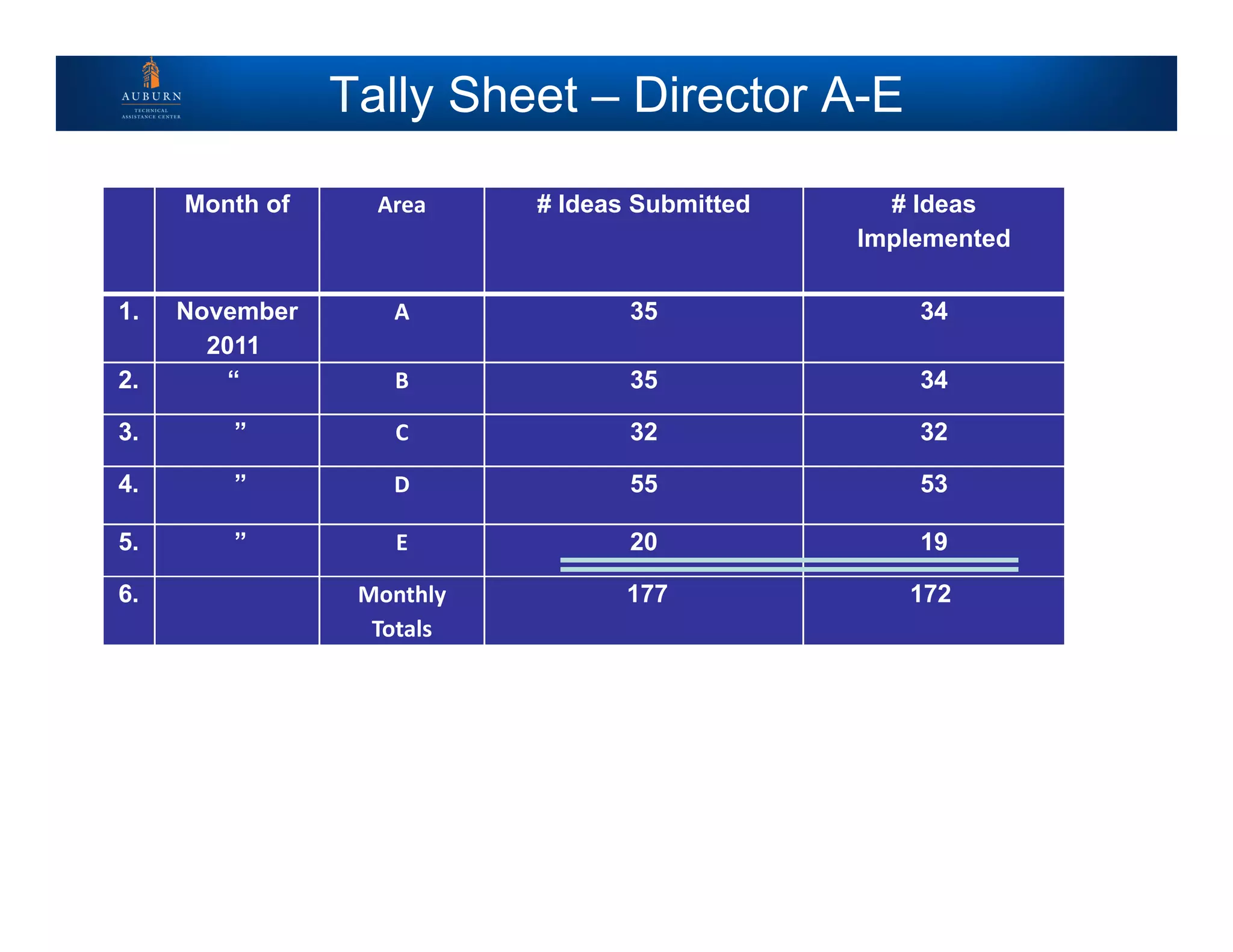

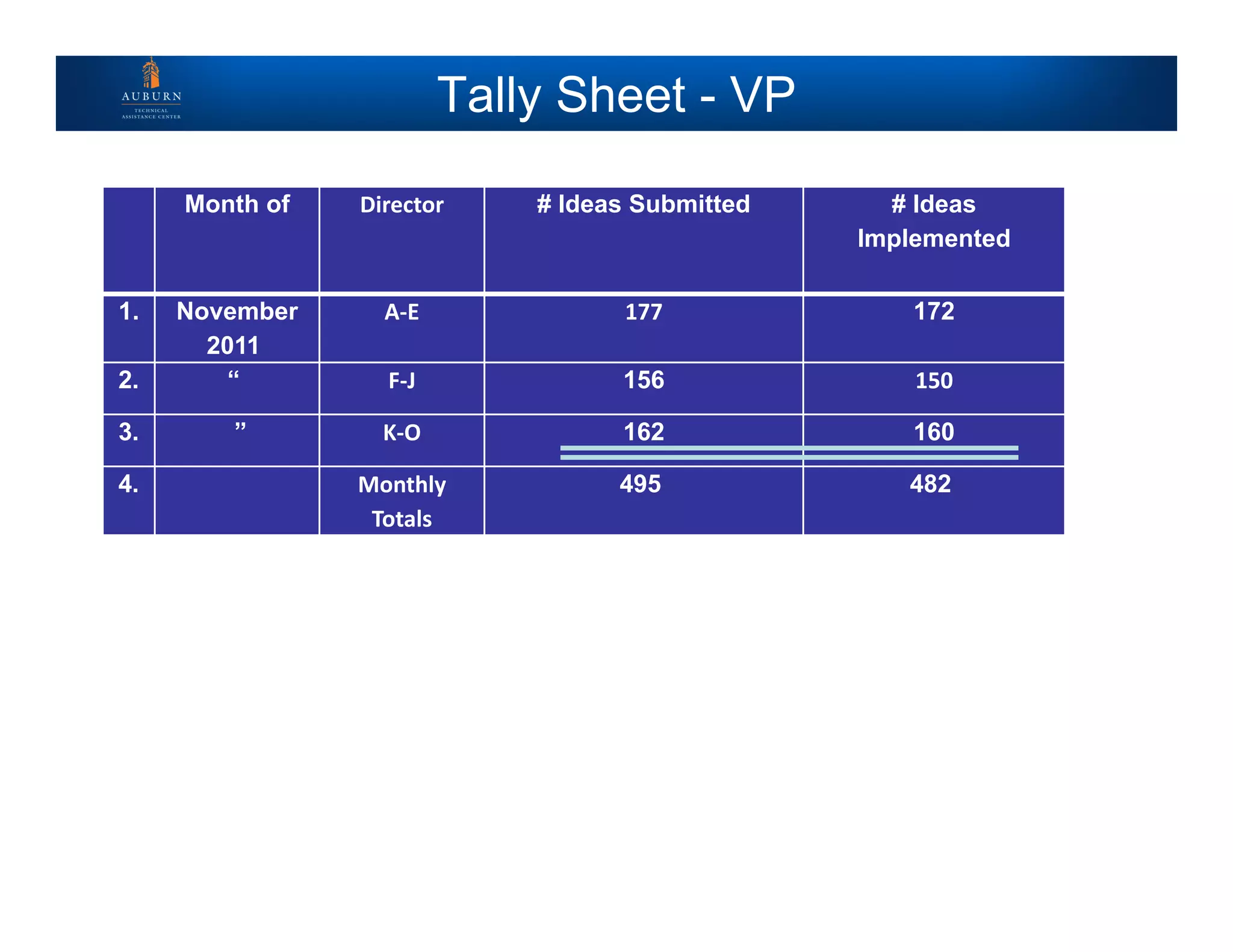

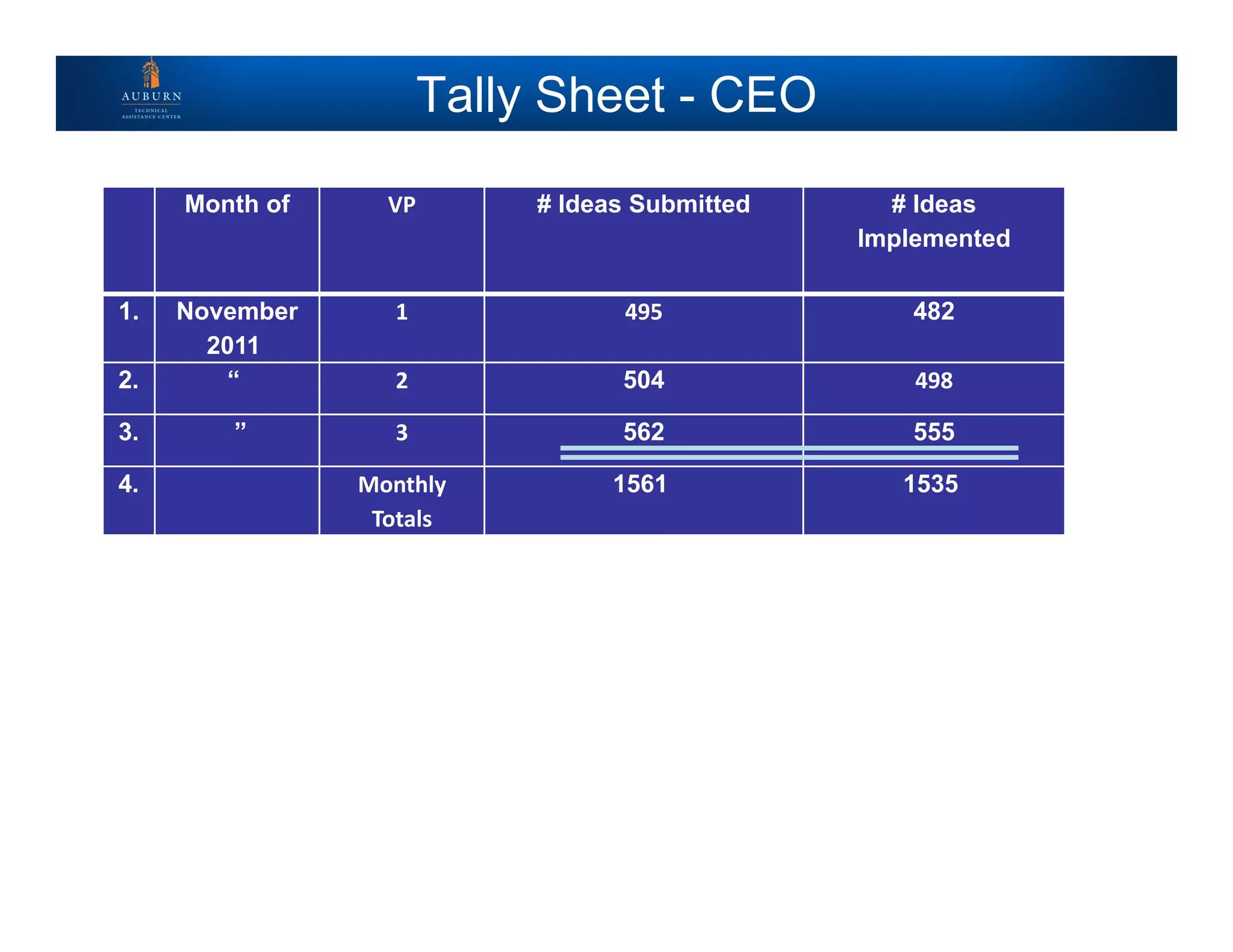

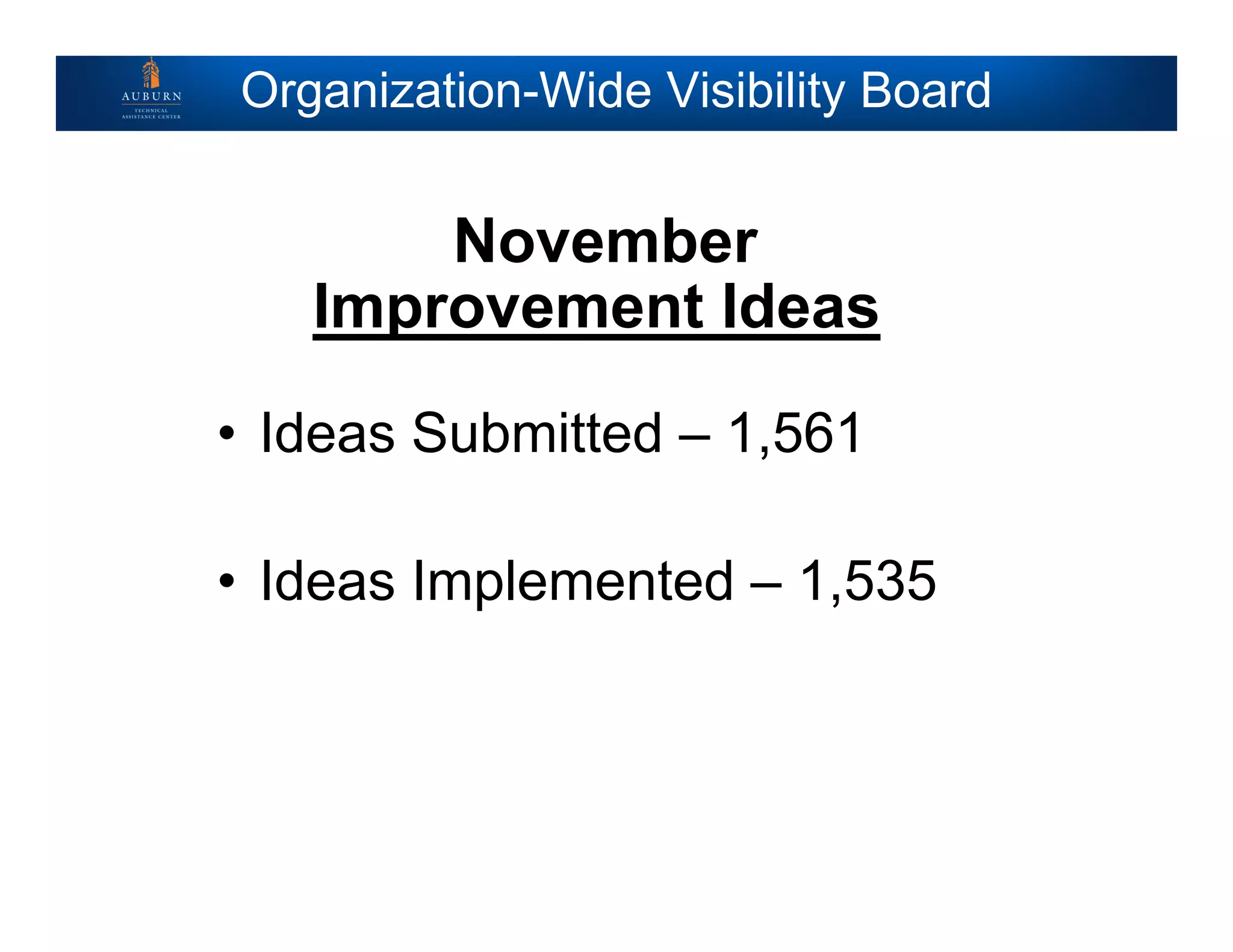

The document describes the concept of Lean and improvement idea boards, noting that Lean focuses on eliminating waste to increase value for customers. It explains that an improvement idea board is a transparent system for collecting, prioritizing, and implementing employee ideas to solve problems and continuously improve processes. Key aspects like leadership engagement, metrics, and culture change are needed to fully realize the benefits of idea boards in driving daily improvements.