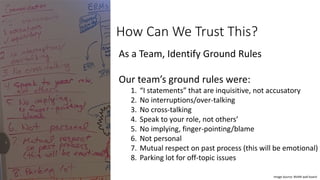

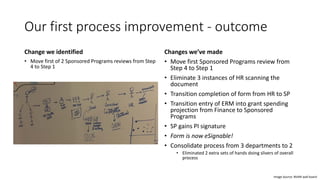

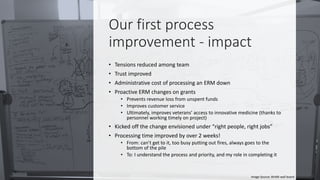

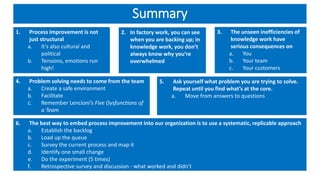

1) Process improvement requires both structural changes and addressing cultural and political issues that cause tensions.

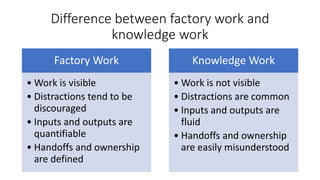

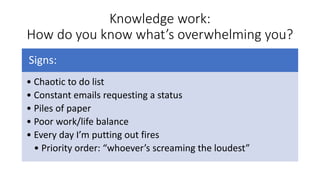

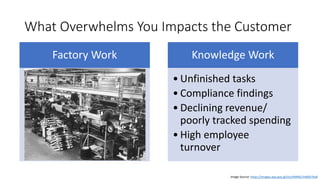

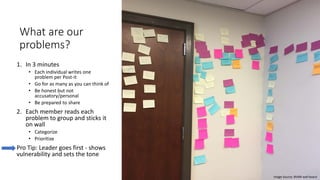

2) In knowledge work, unlike factory work, it is difficult to see what is overwhelming employees and causing inefficiencies. These unseen issues seriously impact employees, their work, and customers.

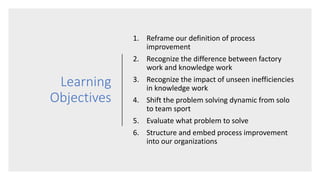

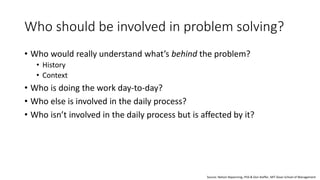

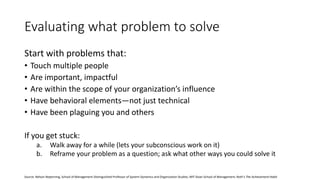

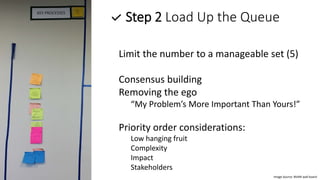

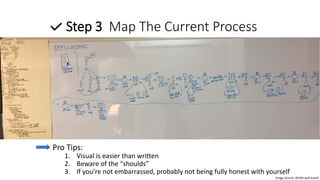

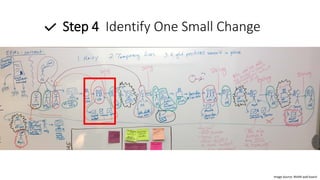

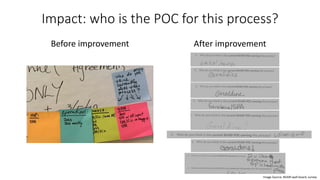

3) A systematic approach is needed to embed process improvement, including establishing problems to address, experimenting with small changes, evaluating impacts, and continuously improving processes. This approach helps organizations solve problems from a team perspective rather than relying only on leaders.