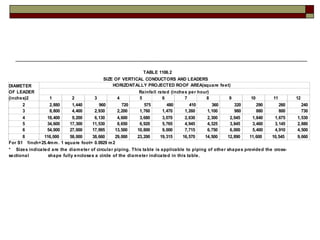

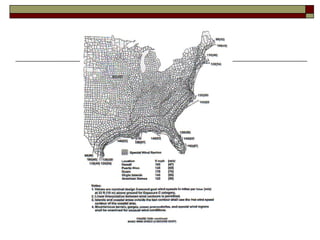

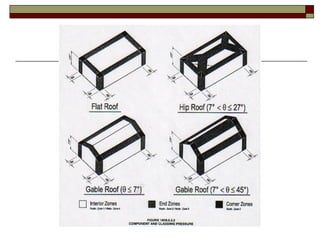

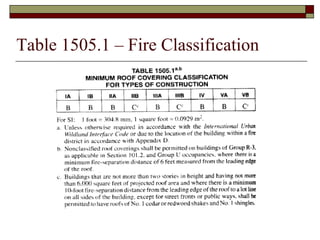

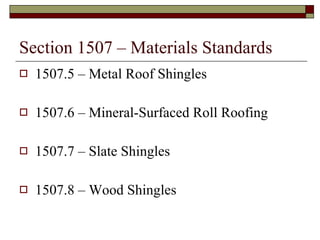

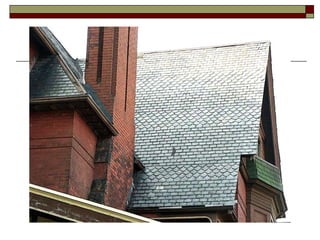

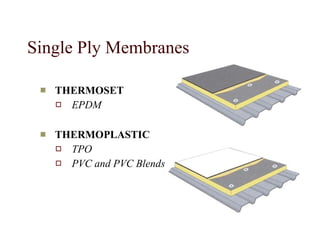

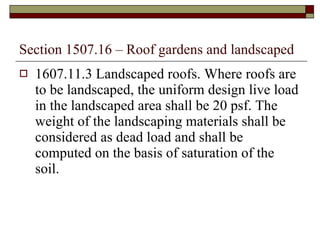

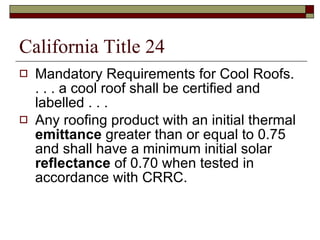

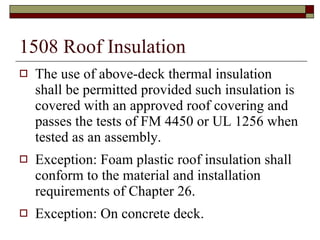

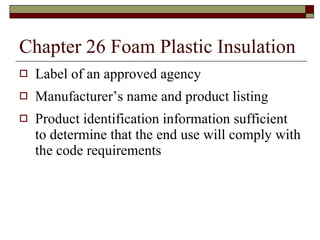

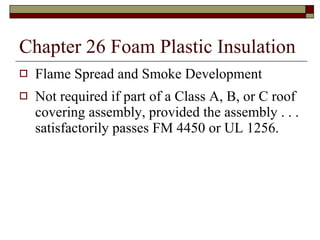

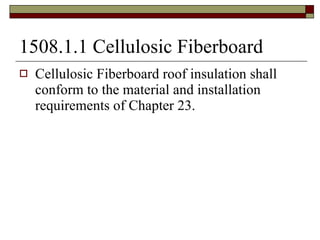

The document summarizes key sections of the International Building Code (IBC) related to commercial roofing. It defines terms used for various roofing materials and systems. It also outlines requirements for weather protection, wind resistance, fire classification, drainage, and performance of roof coverings and assemblies. Secondary roof drainage systems are required where water could become trapped, and must have separate piping from primary drainage systems.