This document provides case studies for four projects related to waste water and reuse:

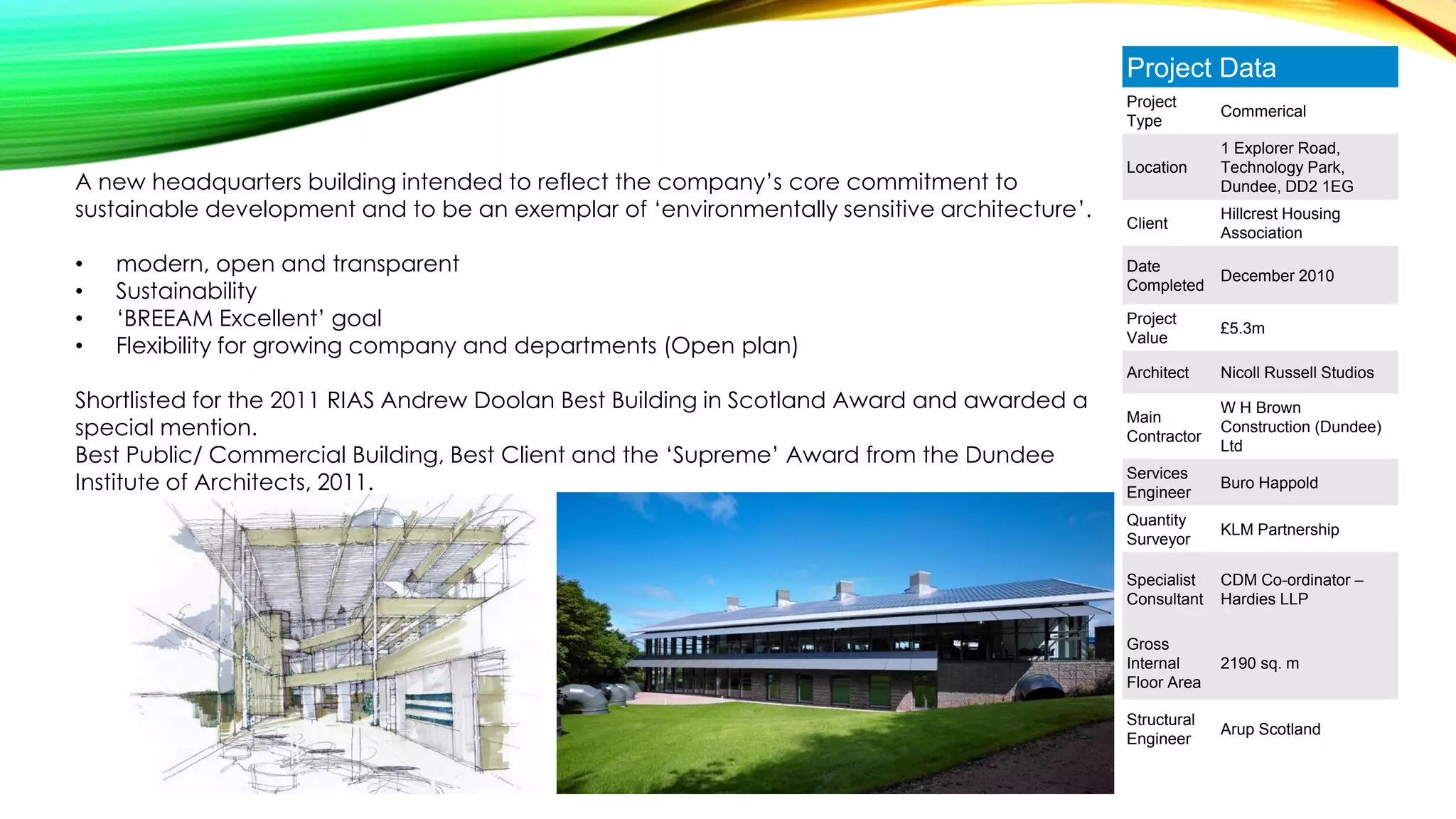

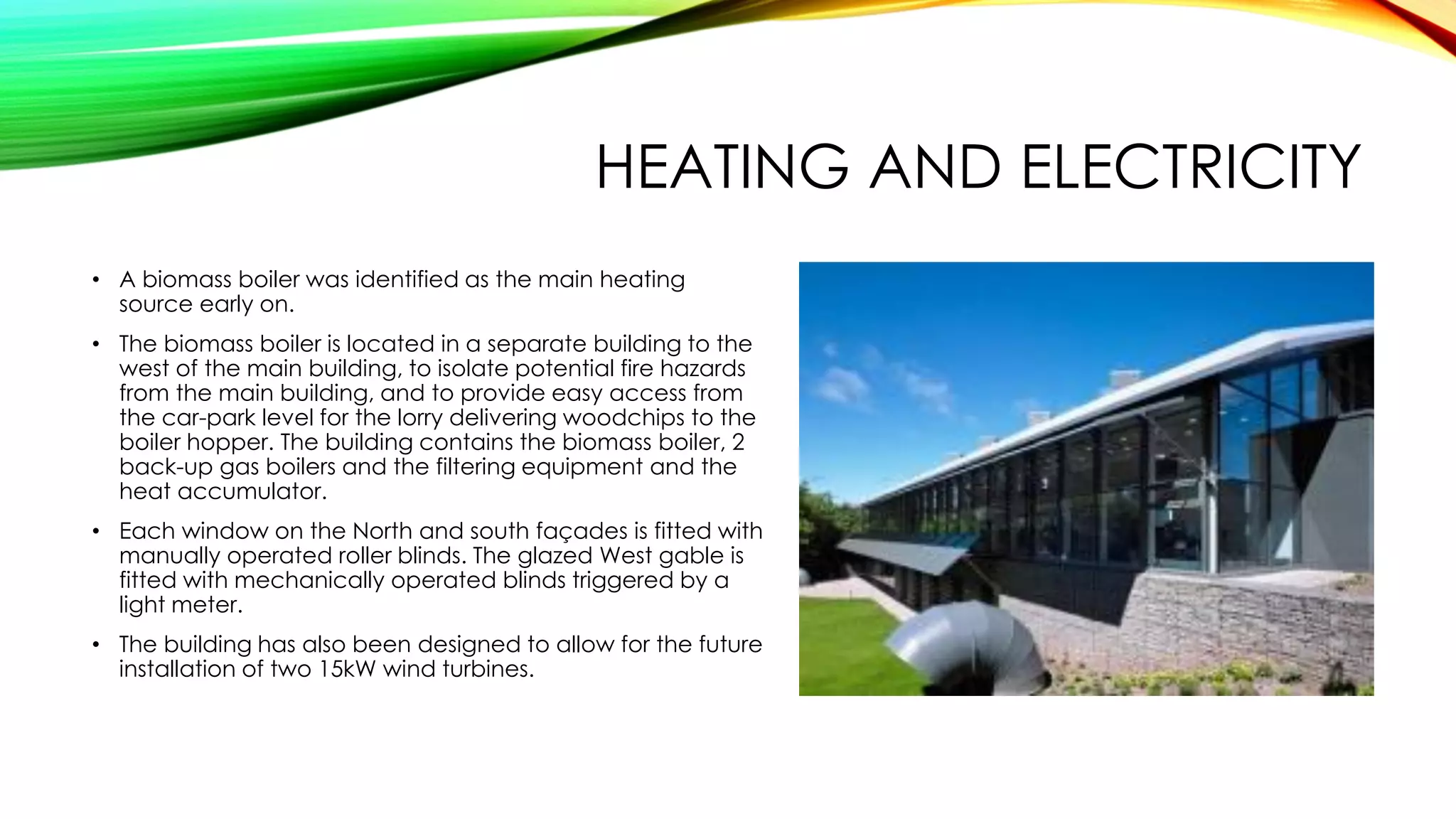

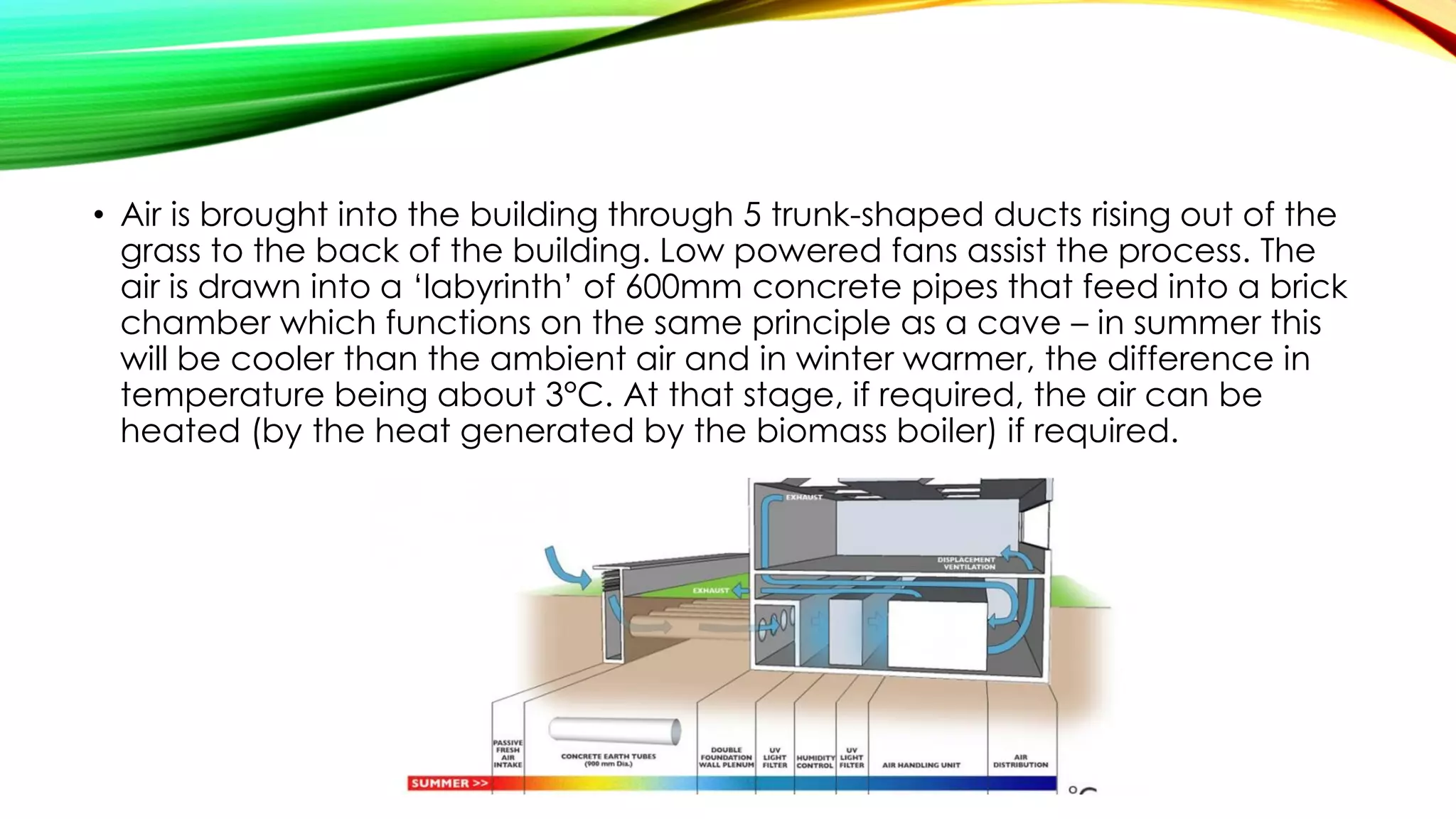

1) Hillcrest Housing Association HQ focused on sustainability through a biomass boiler, earth tubes for ventilation, and rainwater recycling.

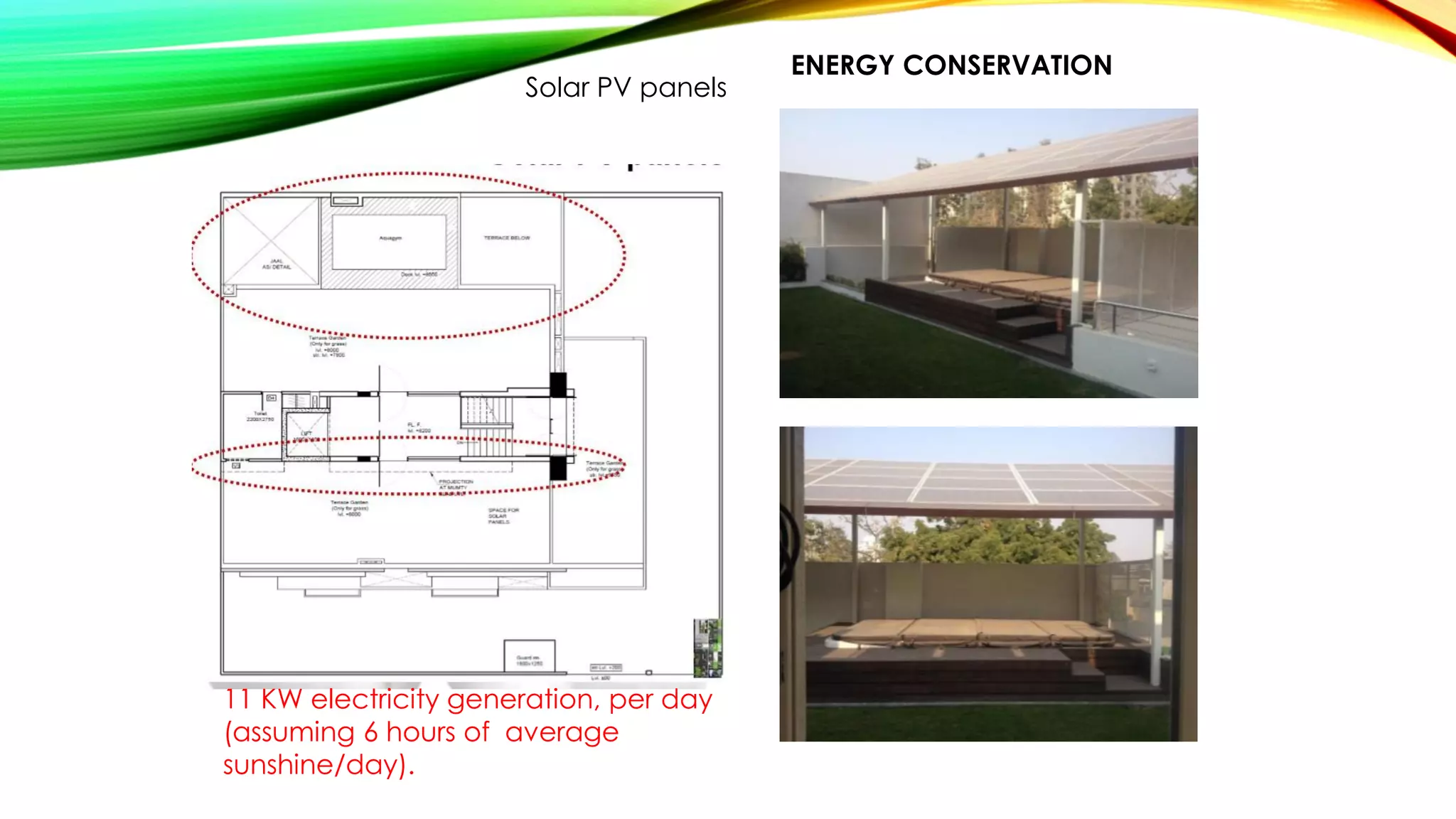

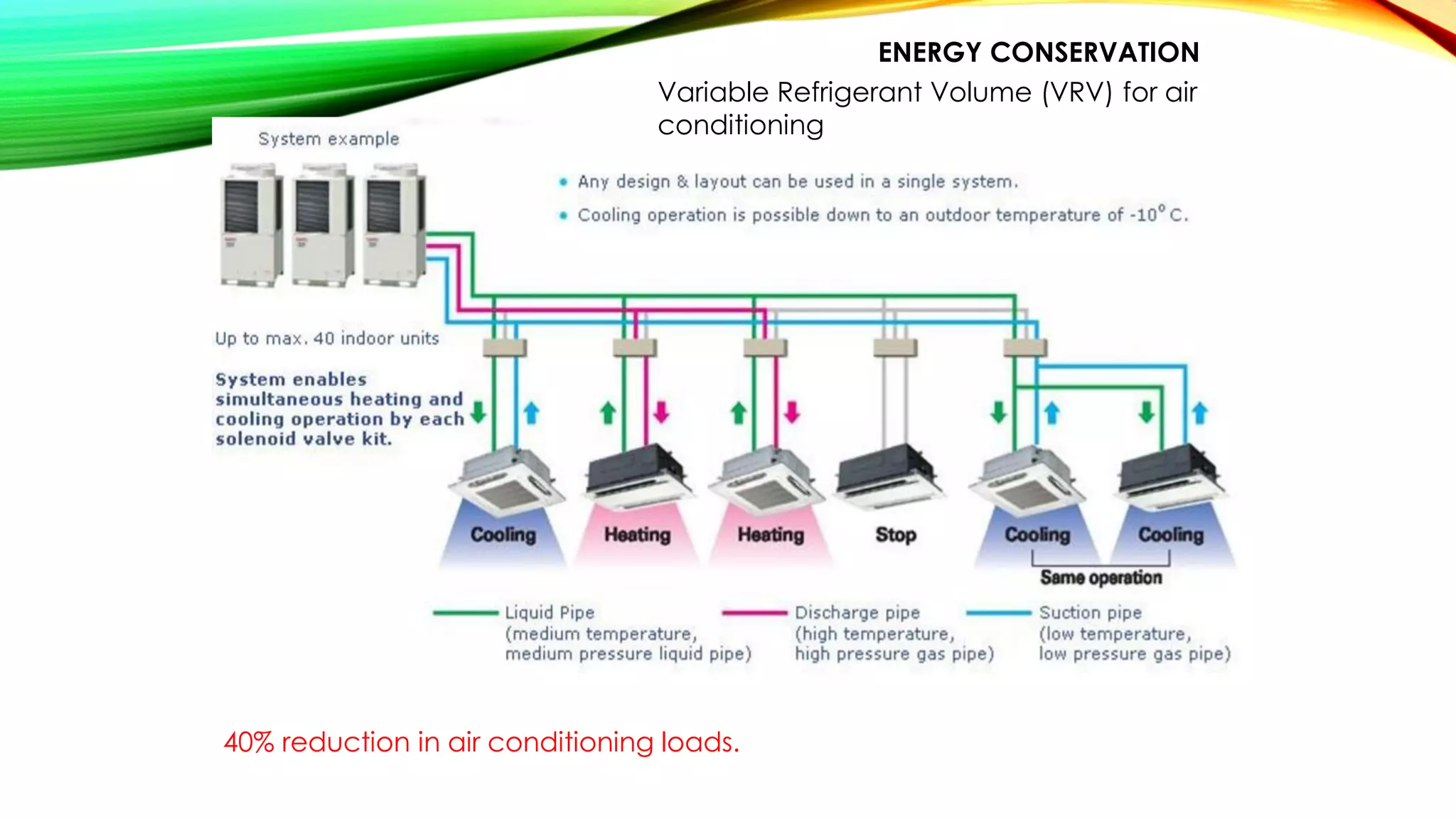

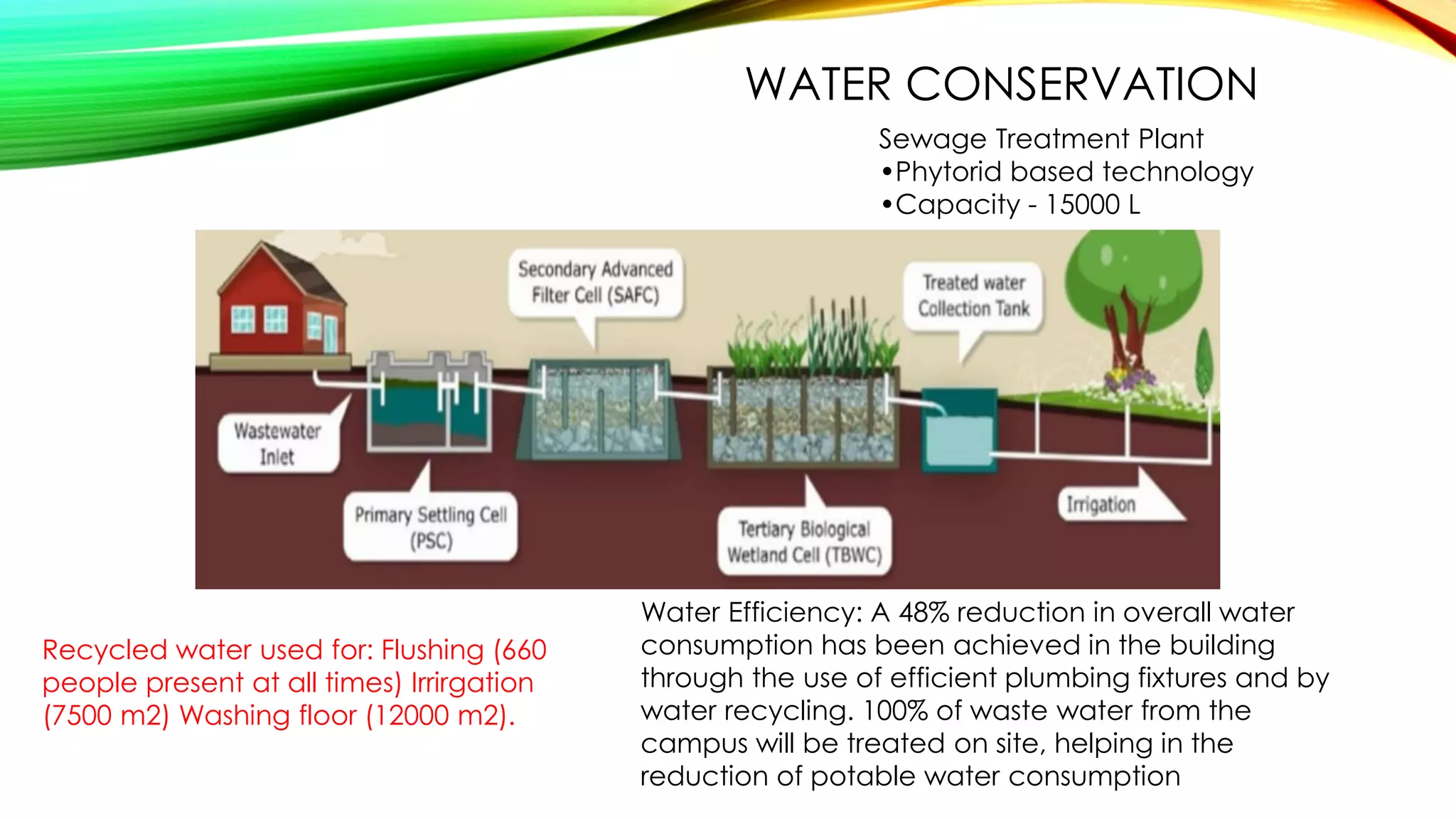

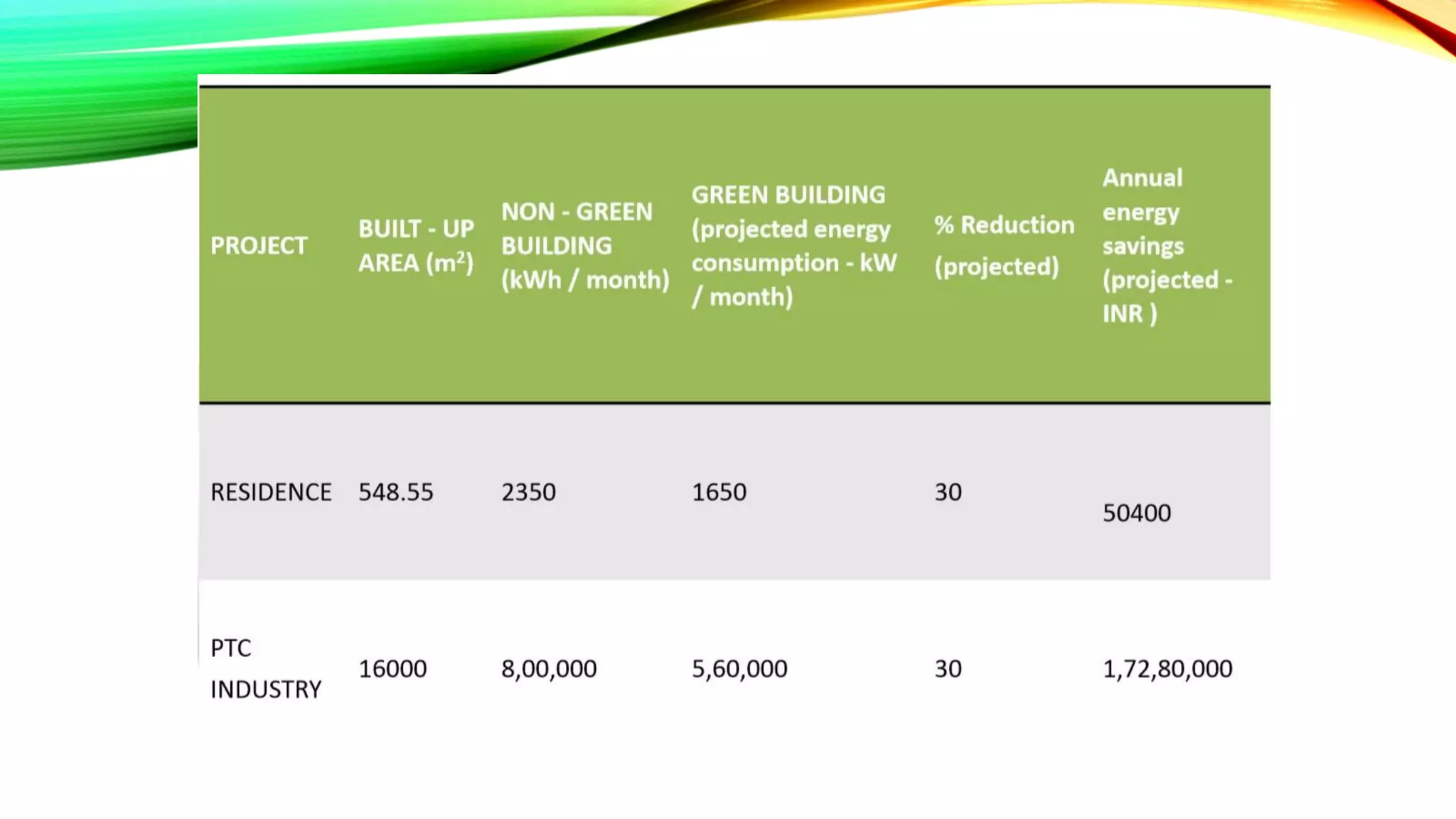

2) The Architect's House in Lucknow, India prioritized green spaces, solar power, and wastewater treatment and reuse.

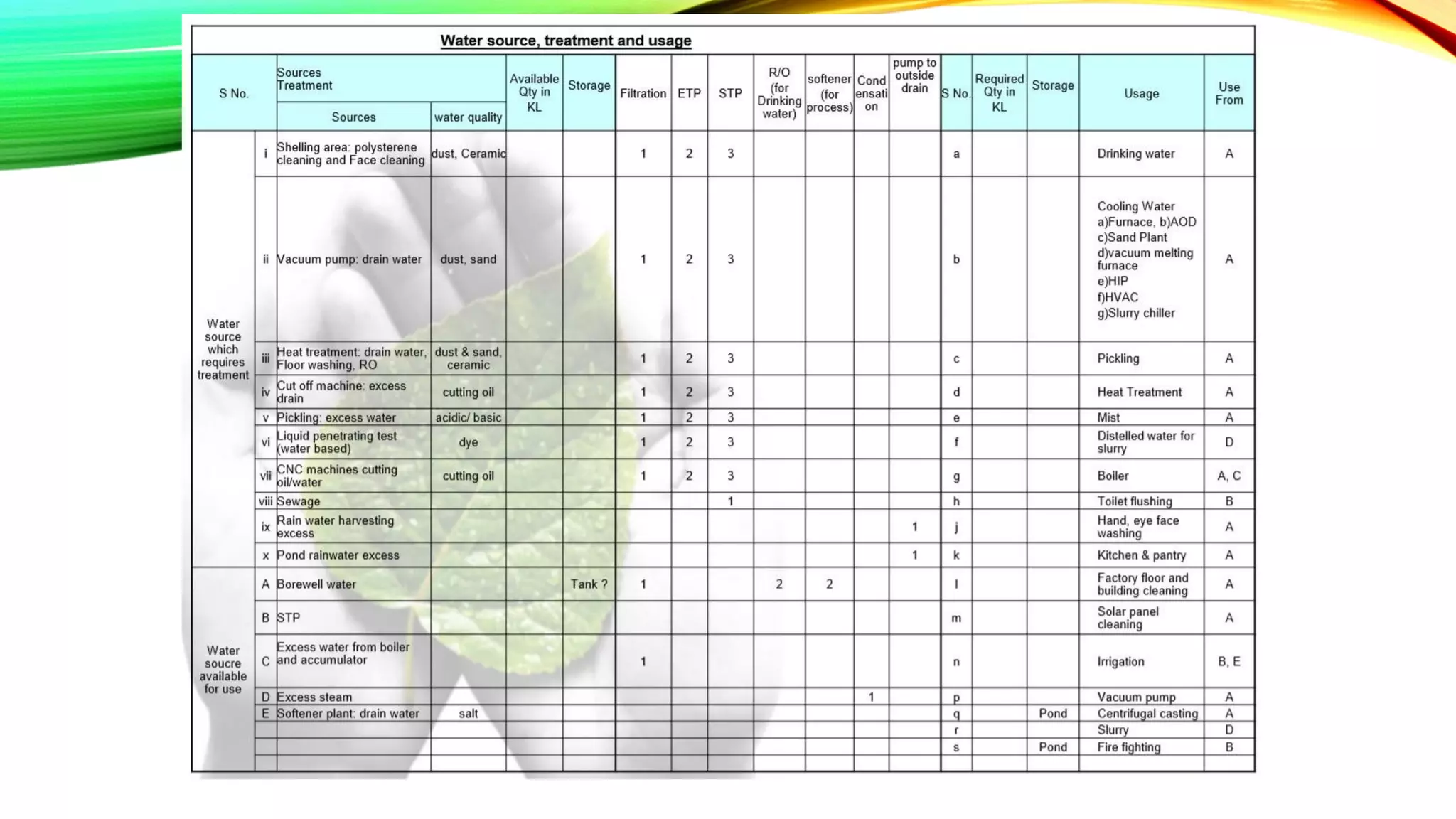

3) PTC Industries HQ aimed for LEED platinum through preserving trees, minimizing turf, harvesting rainwater, and generating solar power onsite.

4) The Mamak Recycling Center processes waste through anaerobic digestion to produce biogas and compost while recycling materials.