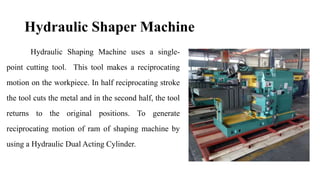

The hydraulic shaper machine uses a single-point cutting tool that makes a reciprocating motion to cut metal on the workpiece during half of its stroke and returns to its original position during the other half. A hydraulic dual-acting cylinder generates the reciprocating motion of the ram. Key parts include a fixed double-acting cylinder, spool-type DC valve, pump, and pressure relief valve. It offers advantages like the ability to change stroke length and speed while running and more uniform cutting due to constant cutting and return speeds.