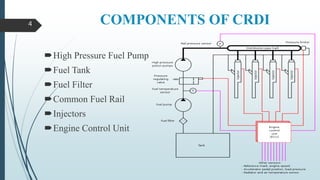

This document provides information about common rail diesel injection systems. It discusses the components of a common rail system including the high pressure fuel pump, fuel rail, injectors, and engine control unit. It explains how these components work together under electronic control to precisely inject fuel into the engine cylinders. The document also covers the construction, working, advantages and disadvantages of common rail systems compared to conventional diesel injection systems. It provides details on piezoelectric injectors and the optimization of these injectors. Overall, the document presents an overview of common rail diesel injection technology.