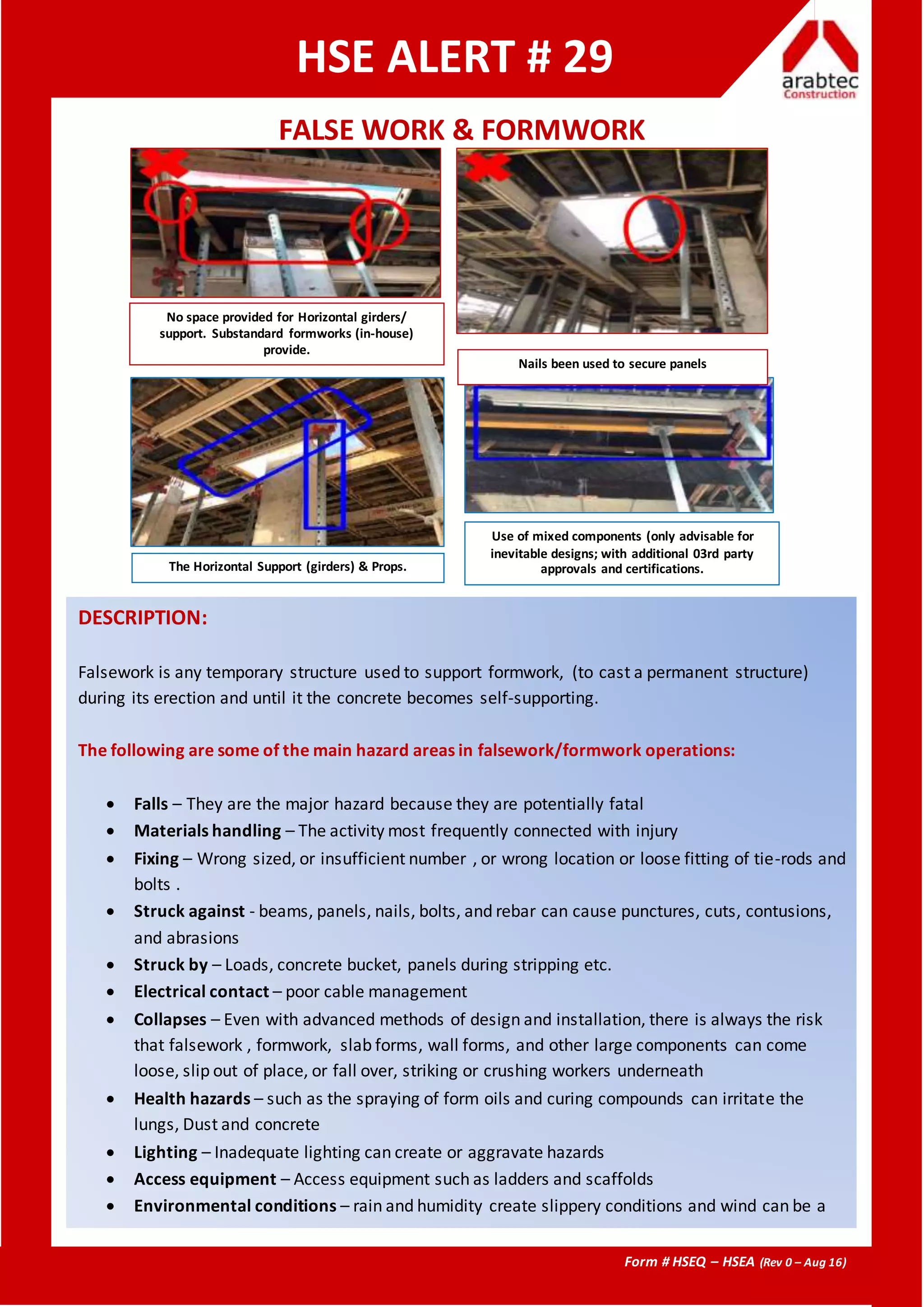

The document discusses hazards associated with falsework and formwork operations during construction projects. Some key hazards identified include falls, materials handling, being struck by objects, collapses, and health issues. Contributing factors for incidents include unauthorized modifications to the formwork without approval, shortcutting approved safety processes, early removal of formwork before concrete is set, and use of damaged or substandard components. The document recommends control measures like having the formwork designed and inspected by engineers, using permit systems, competent supervision, fall protection, barricades, lighting, and following approved safety plans.