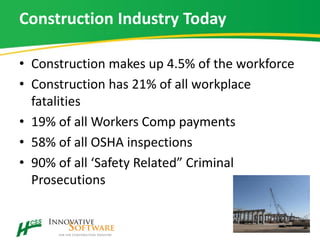

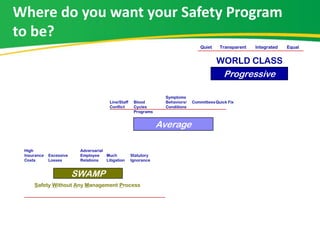

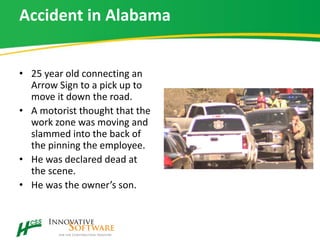

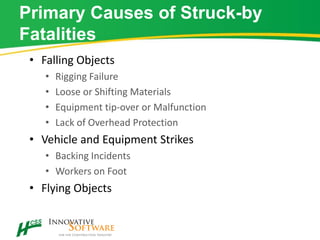

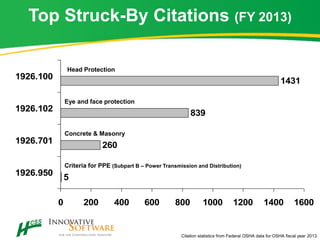

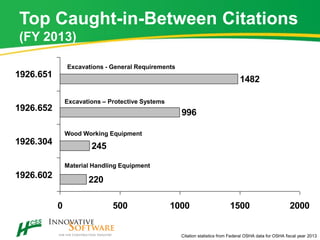

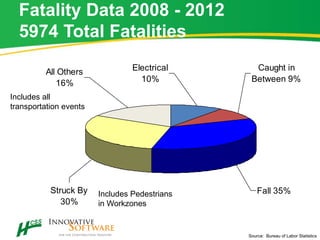

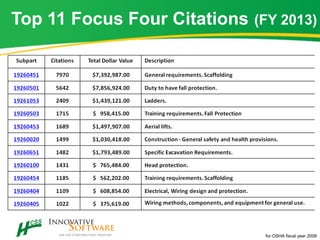

The construction industry, comprising 4.5% of the workforce, is responsible for 21% of workplace fatalities, primarily due to four key hazards: struck-by, caught-in-between, fall, and electrical hazards. Recent fatal incidents highlight the urgent need for improved safety measures, as 81% of fatalities are linked to these hazards. Best practices for enhancing safety programs include management commitment, safety training, employee involvement, and continuous learning to prevent recurrences.